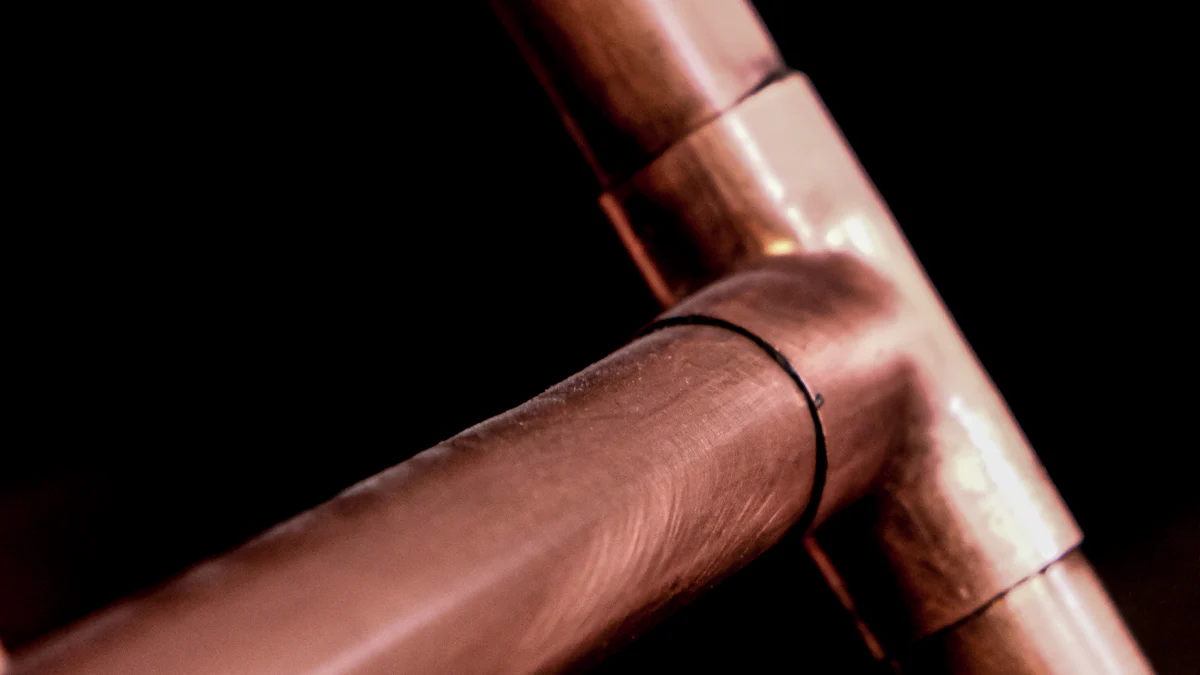

How to Avoid Common Mistakes When Reaming Copper Pipes

How to avoid common mistakes when reaming copper pipes

Reaming copper pipes is a critical step in plumbing that should never be overlooked. Licensed General Contractor emphasizes the necessity of this process, highlighting that neglecting to ream can lead to disastrous consequences over time. To avoid potential issues such as vortex formation and subsequent leaks, understanding the common mistakes associated with reaming is paramount. This blog aims to guide individuals on the proper techniques and safety measures required for effective pipe reaming, ensuring long-lasting and secure plumbing systems.

Incorrect Tool Usage

When it comes to reaming copper pipes, selecting the appropriate tool is crucial for a successful outcome. Licensed General Contractor stresses the significance of this initial step to avoid common mistakes when reaming copper pipes.

Selecting the Right Tool

To begin, using a deburring tool is the most effective method for reaming copper pipes accurately. This tool is specifically designed to remove burrs from the inside of the pipe, ensuring a smooth and clean finish. Alternatively, if a deburring tool is not available, a pipe knife can serve as a suitable substitute for delicate reaming.

Tool Maintenance

In addition to choosing the right tool, proper maintenance is essential for consistent performance. Keeping tools sharp guarantees precise reaming results without causing damage to the pipe. Moreover, storing tools correctly in a dry and secure environment prolongs their lifespan and ensures they are readily available when needed.

Inadequate Reaming Technique

Improper reaming technique can lead to significant issues in plumbing systems. To ensure a successful outcome, individuals must follow the correct reaming method meticulously.

Proper Reaming Method

To begin the reaming process, start by carefully inspecting the pipe for any irregularities. Next, select the appropriate deburring tool based on the pipe's diameter. Insert the tool into the pipe and rotate it gently to remove any burrs effectively. After completing the reaming process, inspect the inside of the pipe to verify a smooth finish.

Step-by-Step Guide

Inspect the pipe for imperfections.

Choose a suitable deburring tool.

Insert and rotate the tool gently.

Verify a smooth finish post-reaming.

Common Errors

Applying excessive force while reaming.

Neglecting to check for burrs post-reaming.

Ensuring Full Diameter

Maintaining the full diameter of copper pipes is crucial to prevent erosion-corrosion and ensure optimal functionality.

Checking for Burrs

After reaming, visually inspect the inside of the pipe to confirm that all burrs have been removed successfully. Run your fingers along the inner surface to detect any remaining imperfections.

Avoiding Erosion-Corrosion

By reaming copper pipes correctly, you eliminate potential turbulence that can lead to erosion-corrosion over time. This meticulous process guarantees a seamless flow within your plumbing system, preventing future complications.

Ignoring Safety Measures

When reaming copper pipes, safety measures are paramount to prevent accidents and ensure a secure working environment. Licensed General Contractor emphasizes the importance of prioritizing safety at all times.

Personal Protective Equipment

When handling tools for reaming, it is crucial to wear the appropriate personal protective equipment (PPE) to safeguard against potential hazards. Gloves and goggles are essential gear that shields individuals from sharp edges and debris during the reaming process. By wearing these protective items, workers can minimize the risk of injuries and maintain a safe work environment.

Gloves and Goggles

Wear sturdy gloves to protect hands from cuts.

Use goggles to shield eyes from debris.

Safe Work Environment

Creating a safe work environment is fundamental when reaming copper pipes. Ensuring that the workspace is clear of clutter and obstacles reduces the likelihood of accidents. By maintaining a tidy area, workers can focus on the task at hand without distractions or safety hazards.

Safe Handling of Tools

Properly handling tools is essential for efficient and safe reaming practices. Licensed General Contractor advises individuals on the correct techniques for tool management to avoid mishaps during the process.

Proper Grip

Maintain a firm grip on the tool while reaming.

Ensure hands are dry for better control.

Avoiding Slips

To prevent slips or accidental injuries, it is vital to handle tools with care and attention. By using tools with precision and caution, individuals can complete the reaming process smoothly without compromising safety standards.

Neglecting Pipe Preparation

When preparing the pipe for reaming, attention to detail is crucial to ensure a seamless process. Neglecting this essential step can lead to complications down the line, affecting the overall integrity of the plumbing system.

Cleaning the Pipe

Before proceeding with reaming, it is imperative to clean the pipe thoroughly to eliminate any potential obstructions that could impede the reaming process.

Removing Debris

Begin by removing any debris or foreign particles from both the interior and exterior of the pipe. This meticulous cleaning ensures a smooth reaming operation without encountering unexpected obstacles.

Polishing the Surface

After debris removal, polishing the surface of the pipe enhances its condition and facilitates a more efficient reaming process. Utilize silicon carbide sandpaper with medium to fine grit sizes for optimal results.

Inspecting the Cut

Inspecting the cut post-reaming is essential to guarantee that all necessary steps have been executed correctly, ensuring a flawless outcome.

Checking for Smooth Edges

Verify that the edges of the pipe are smooth and free from any imperfections that could hinder its functionality. Smooth edges indicate a successful reaming process and contribute to optimal performance.

Ensuring Proper Fit

Confirm that the reamed pipe fits seamlessly with other components in your plumbing system. A proper fit guarantees a secure connection and prevents potential leaks or disruptions in flow.

Revisiting the common mistakes made during copper pipe reaming serves as a valuable lesson for all. The importance of precise reaming cannot be overstated, ensuring the longevity of your plumbing system. Embrace the best practices outlined in this blog to safeguard against future complications and maintain a seamless flow within your pipes.

See Also

Steer Clear of These 5 Mistakes When Soldering Copper Pipes

Top 5 Tips for Utilizing 1/4 Copper Pipe Fittings

Basic Guide: Soldering Copper Pipes for Newbies