What Are the Top Materials for Insulating AC Pipes?

What are the best materials for insulating AC pipes? Insulating AC pipes is crucial for optimal system performance. Proper insulation not only enhances energy efficiency but also prevents heat loss, ensuring a well-regulated cooling process. By understanding the significance of insulating AC pipes, individuals can make informed decisions to improve their HVAC systems. This blog delves into the benefits of insulation, guiding readers through top materials and essential considerations for selecting the right insulation type.

Understanding the Need for Insulation

Heat Transfer in AC Systems

Conduction

Conduction, the process of heat transfer through direct contact, plays a significant role in the efficiency of AC systems. Materials with high thermal conductivity facilitate rapid heat transfer, affecting the overall performance of the system. Insulating AC pipes effectively reduces conduction, minimizing energy loss and enhancing system efficiency.

Convection

In AC systems, convection refers to heat transfer through fluid movement. Proper insulation inhibits convective heat exchange by creating a barrier between the pipe surface and the surrounding air. By reducing convective heat loss, insulation helps maintain consistent temperatures within the system, promoting optimal cooling operations.

Radiation

Radiation is another form of heat transfer that occurs through electromagnetic waves. Insulating AC pipes with suitable materials can reflect or absorb radiant heat, preventing unnecessary energy dissipation. By addressing radiation through insulation, AC systems can operate more efficiently and sustainably.

Energy Efficiency

Reducing Energy Loss

Effective insulation minimizes energy loss by limiting heat transfer mechanisms within AC systems. By mitigating conduction, convection, and radiation losses, insulation ensures that the cooling process remains efficient and cost-effective. This reduction in energy loss contributes to overall energy efficiency and environmental sustainability.

Cost Savings

Insulating AC pipes not only enhances energy efficiency but also leads to substantial cost savings for homeowners and businesses alike. By reducing the workload on HVAC systems through proper insulation practices, individuals can lower their utility bills and maintenance expenses over time. Investing in quality insulation materials translates to long-term financial benefits and improved system performance.

Preventing Condensation

Moisture Control

Condensation can pose a threat to AC systems if left unchecked. Proper insulation helps control moisture levels by creating a barrier that prevents condensation buildup on pipes. By regulating humidity and temperature variations, insulation safeguards against potential water damage and corrosion issues within the system.

Mold Prevention

In environments where moisture is prevalent, mold growth can become a serious concern for AC systems. Insulation plays a crucial role in mold prevention by maintaining consistent temperatures that discourage mold formation. By addressing condensation risks proactively with adequate insulation measures, individuals can protect their AC systems from harmful mold infestations.

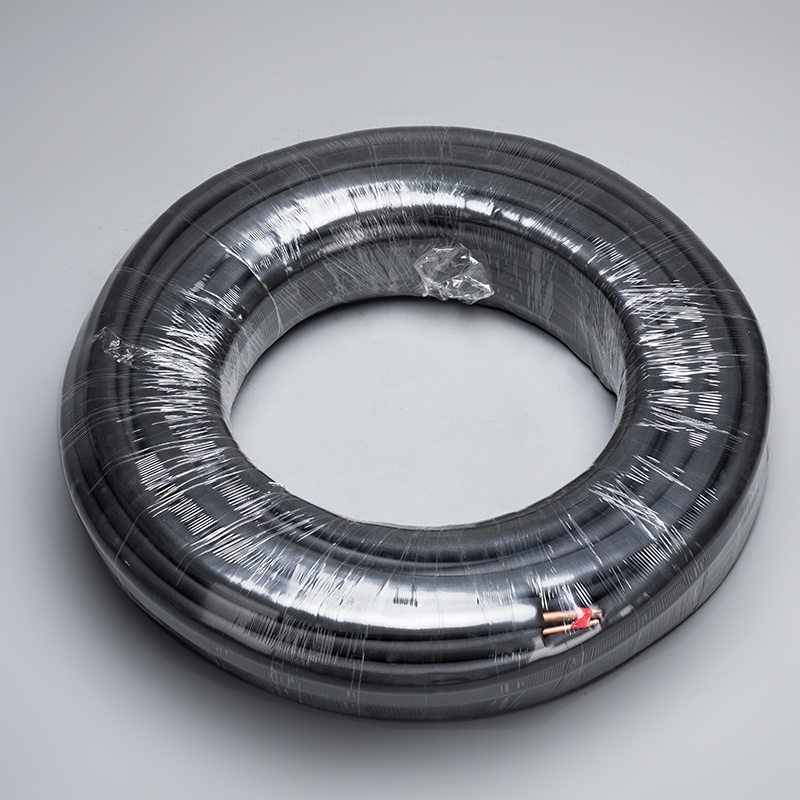

Top Materials for Insulating AC Pipes

Foam Insulation

Foam insulation is a popular choice for insulating AC pipes due to its versatility and effectiveness. Polyethylene Foam is a lightweight material that offers excellent thermal insulation properties, making it ideal for maintaining consistent temperatures within the system. This type of foam is easy to install and provides a reliable barrier against heat transfer.

When it comes to foam insulation, Elastomeric Foam stands out for its durability and moisture resistance. This material is specifically designed to prevent moisture intrusion in AC pipes, ensuring long-term protection against condensation issues. Elastomeric foam is known for its flexibility, making it easy to wrap around pipes of various shapes and sizes.

Fiberglass Insulation

Properties of Fiberglass make it a preferred choice for insulating AC pipes in both residential and commercial settings. Fiberglass insulation offers excellent thermal performance, reducing energy loss and enhancing overall system efficiency. Its lightweight nature and flexibility make it easy to work with during installation.

For those considering fiberglass insulation, Installation Tips can streamline the process and ensure optimal results. Properly cutting and fitting fiberglass insulation around AC pipes is crucial for maximizing its effectiveness. Additionally, sealing any gaps or joints in the insulation can further enhance its performance and longevity.

Rubber Insulation

Rubber insulation is another reliable option for insulating AC pipes, known for its durability and versatility. The Characteristics of Rubber include resistance to moisture, UV exposure, and extreme temperatures, making it suitable for various environmental conditions. Rubber insulation provides an effective thermal barrier while offering long-lasting protection.

When determining the best use cases for rubber insulation, consider applications where flexibility and resilience are essential. Rubber insulation is commonly used in HVAC systems where vibration dampening and noise reduction are required. Its ability to withstand harsh conditions makes it a practical choice for insulating AC pipes in diverse settings.

Reflective Insulation

How Reflective Insulation Works

Reflective foil insulation, known for its thin and lightweight properties, operates by reflecting heat away from surfaces. When installed in AC systems, Reflective Foil Insulation effectively minimizes heat transfer through its reflective surface. By bouncing radiant heat off the material, it helps maintain consistent temperatures within the pipes. This process enhances energy efficiency and prevents unnecessary heat loss.

To understand how reflective insulation works, consider its ability to create a thermal barrier. The reflective surface of the insulation deflects incoming heat, preventing it from penetrating the pipes. This mechanism reduces the workload on the AC system by minimizing heat absorption, leading to improved cooling performance.

Reflective insulation is commonly chosen for home remodels and construction projects due to its cost-effectiveness and durability. Its reflective nature not only saves money on energy bills but also ensures long-term effectiveness. By incorporating Reflective Foil Insulation into AC pipe insulation, individuals can enhance system efficiency while prolonging the lifespan of their HVAC components.

Pros and Cons

When evaluating the benefits of reflective insulation, several advantages come to light:

Reflective foil insulation offers excellent thermal resistance, reducing heat transfer significantly.

It is a cost-effective solution that provides long-lasting performance without compromising quality.

The lightweight nature of reflective insulation simplifies installation processes and handling.

By preventing moisture buildup, this type of insulation safeguards against corrosion and mold growth.

Despite its numerous advantages, reflective insulation also has some limitations:

Reflective foil may require additional support in windy conditions to prevent displacement.

Installation errors such as gaps or overlaps can diminish the effectiveness of reflective insulation.

In areas with high humidity levels, condensation may form on the outer surface of reflective foil.

Overall, Reflective Foil Insulation remains a valuable choice for insulating AC pipes, offering a balance of efficiency and affordability for optimal system performance.

How to Choose the Right Insulation Material

Climate Considerations

When selecting insulation materials for AC pipes, consideration of the climate is crucial to ensure optimal performance. In hot climates, insulation should effectively minimize heat transfer and prevent energy loss. Materials that can withstand high temperatures and UV exposure are ideal for maintaining insulation integrity in such environments. Conversely, in cold climates, insulation must provide sufficient thermal resistance to combat heat loss and condensation issues.

Pipe Material Compatibility

Compatibility with different pipe materials is a significant factor in choosing the right insulation. For metal pipes, it is essential to select materials that offer corrosion resistance and thermal stability. Insulation products designed for metal pipes should provide a secure fit and durable protection against external elements. When insulating plastic pipes, focus on materials that are compatible with plastic surfaces without causing damage or chemical reactions.

Budget and Cost-Effectiveness

Balancing budget constraints with long-term cost-effectiveness is key when deciding on insulation materials for AC pipes. While considering initial costs, evaluate the overall value and performance offered by each material. Opt for insulation solutions that not only meet budget requirements but also deliver efficient thermal protection over time. Prioritizing long-term savings ensures that investments in quality insulation pay off through energy efficiency and reduced maintenance expenses.

Insulating AC pipes is a critical step in enhancing system efficiency and reducing energy costs. By choosing the right materials, individuals can significantly impact their HVAC systems' performance. The discussed top materials, including Polyethylene Foam, Elastomeric Foam, Fiberglass Insulation, Rubber Insulation, and Reflective Foil Insulation, offer unique benefits tailored to various needs. Selecting insulation based on climate considerations, pipe material compatibility, and budget constraints ensures long-term effectiveness. Take action now to improve energy efficiency and enjoy cost savings with proper AC pipe insulation.

See Also

Uncover the Key to Improving AC Efficiency with Copper

Essential Insulation Options for Copper Pipe Knowledge

Exploring the Optimal Home Pipe Insulation