How to Choose the Right Size Copper Pipe for Your Plumbing Project

When embarking on a plumbing project, the importance of selecting the right size copper pipe cannot be overstated. Various factors come into play when determining the appropriate pipe size, influencing the efficiency and success of your endeavor. For instance, choosing between a 1 2 inch copper pipe, a 1 1/4 in copper pipe, or a 1/2 inch copper pipe can significantly impact your project. Additionally, understanding the 1 2 copper pipe od and the 3 4 inch coppe is crucial for a seamless plumbing experience. Whether you are a seasoned DIY enthusiast or a novice in the realm of plumbing, making informed decisions about copper pipe sizes is key to achieving optimal results.

Factors to Consider

Pressure and Flow Rate

Understanding Pressure

To ensure the efficiency of your plumbing system, it is vital to grasp the concept of pressure. Different pipes are made of different materials, impacting the flow rate. When calculating pipe size, consider this factor to guarantee optimal performance.

Understanding Flow Rate

The flow rate in your plumbing project is influenced by various factors, including the diameter of the copper pipe. Copper tube sizes are specific for plumbing and potable water systems, so selecting the right size is crucial for a successful installation. Be mindful of these details when determining the appropriate pipe size.

Application Type

Residential vs. Commercial

When choosing a copper pipe size, consider whether it is for residential or commercial use. The application type will dictate the required diameter to meet the demands of the specific setting. Understanding this distinction ensures a tailored and efficient plumbing solution.

Hydronic Applications

For hydronic applications, velocity and pressure drop play a significant role in sizing copper pipes correctly. The material you choose will affect the flow rate, so select wisely based on these considerations. Remember that each application type requires a unique approach to ensure optimal functionality.

Material and Durability

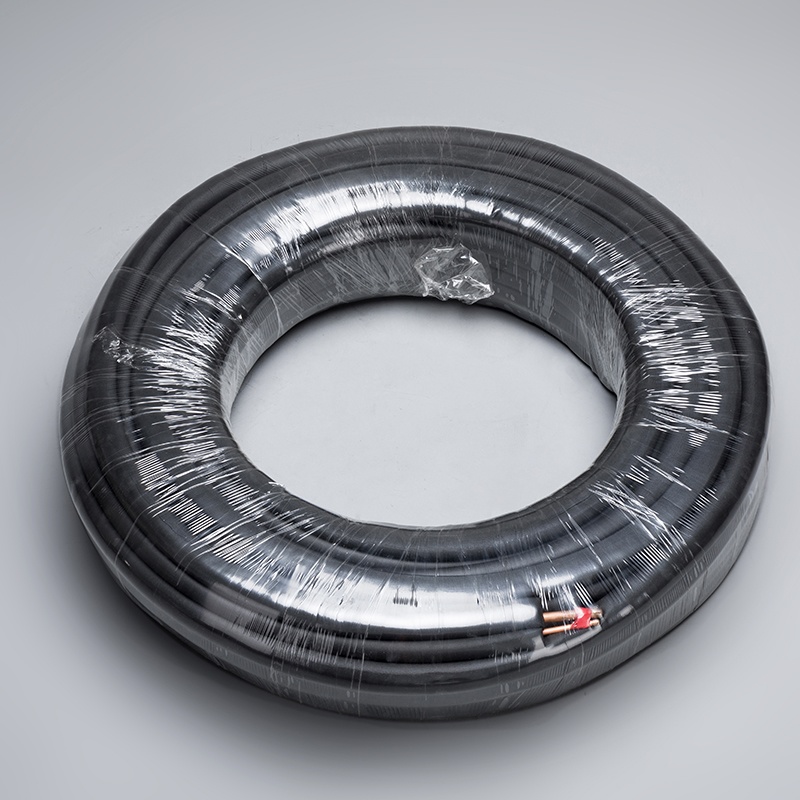

Copper Pipe Types

Selecting the right copper pipe type is essential for longevity and maintenance ease. Different types offer varying levels of durability and corrosion resistance, impacting the lifespan of your plumbing system. Consider these aspects when deciding on the material for your project.

Longevity and Maintenance

Proper maintenance is key to extending the lifespan of your copper pipes. Regular checks and upkeep can prevent issues such as leaks or corrosion, ensuring a reliable plumbing system for years to come. Choose high-quality materials that require minimal maintenance for added convenience.

Measuring and Calculating

Measuring Outer Diameter

Caliper and Measuring Tape: For smaller sizes, use a caliper to directly measure the outer diameter of the pipe. Convert this measurement to the nominal pipe diameter for accuracy.

Flexible Measuring Tape: Wrap the tape around the pipe snugly to ensure an accurate measurement. Make sure it encircles the pipe completely without any gaps or overlaps.

Tools Needed

Caliper and Measuring Tape: Directly measure the outer diameter of smaller pipes.

Flexible Measuring Tape: Wrap it around the pipe for precise measurements.

Step-by-Step Guide

Use a Caliper or Measuring Tape for small pipes.

Ensure a snug fit with the Flexible Measuring Tape.

Calculating Diameter

Tape Measure and Marker: Precision in measurements is crucial for successful DIY projects involving copper pipes. Use these tools to measure accurately.

Using the Formula

Measure with precision using a Tape Measure.

Mark measurements accurately with a Marker.

Example Calculation

Calculate circumference using a measuring tape.

Divide by 3.14 to approximate pipe diameter accurately.

Ensuring Proper Fit

Pipe Cutter: A vital tool for clean and accurate cuts on copper pipes, ensuring seamless fitting during installation.

Checking Compatibility

Verify compatibility before making any cuts.

Ensure proper size alignment for a secure fit.

Avoiding Common Mistakes

Double-check measurements before cutting.

Follow manufacturer guidelines for precise cuts every time.

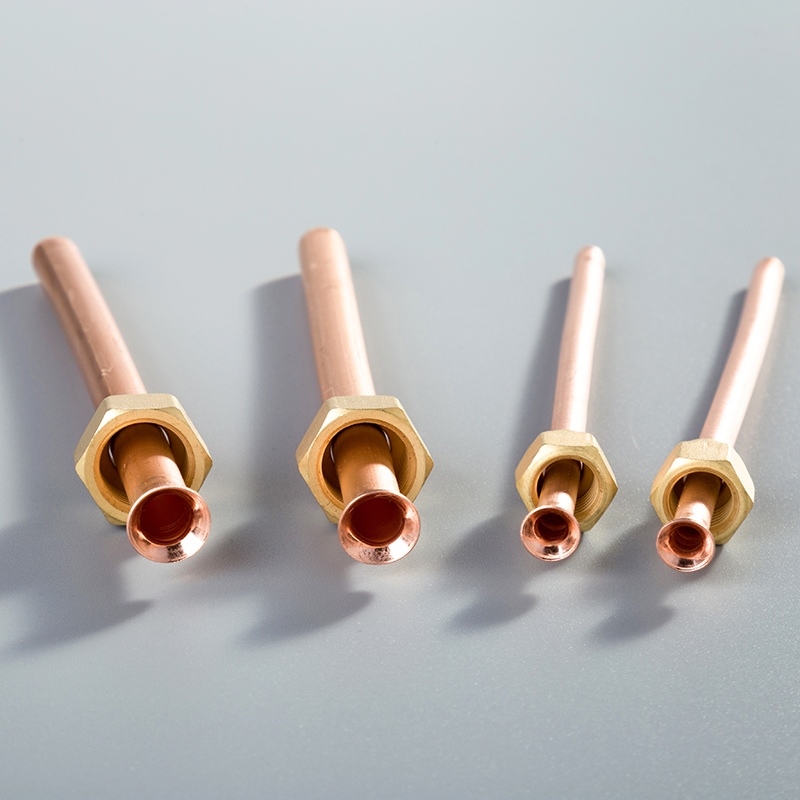

Common Pipe Sizes

1/2 Inch Copper Pipe

When considering 1/2 inch copper pipe, it is essential to understand its uses and applications. This size is commonly utilized in residential plumbing projects for water supply lines and smaller fixtures. The advantage of 1/2 inch copper pipes lies in their versatility and ease of installation. However, one disadvantage is that they may not be suitable for high-demand systems due to potential flow restrictions.

3/4 Inch Copper Pipe

Moving up to a 3/4 inch copper pipe, you'll find broader uses and applications. This size is often preferred for larger residential projects or light commercial settings where increased water flow is necessary. The advantage of 3/4 inch copper pipes is their ability to handle higher volumes of water efficiently. On the downside, they can be more challenging to install in tight spaces compared to smaller sizes.

1 1/4 Inch Copper Pipe

For more demanding applications, such as industrial or commercial projects, 1 1/4 inch copper pipes are a popular choice. These larger pipes are ideal for systems requiring substantial water flow rates or where multiple fixtures need to be supplied simultaneously. The advantage of 1 1/4 inch copper pipes lies in their capacity to handle heavy-duty tasks effectively. However, one drawback is that they may require additional support due to their weight and size.

Recap of Key Points:

Precision in measurements is paramount for successful DIY projects involving copper pipes.

Meticulous measurements are essential to ensure the efficiency and accuracy of your plumbing system.

Understanding the factors influencing pipe size selection is crucial for optimal performance.

Final Recommendations:

Prioritize accurate measurements using the recommended tools for precise results.

Consider all factors, including pressure, flow rate, and application type, when choosing the right copper pipe size.

Regular maintenance and checks are vital to prevent issues and prolong the lifespan of your plumbing system.

Encouragement to Consult Professionals if Needed:

For complex projects or uncertainties in selecting the appropriate copper pipe size, do not hesitate to seek guidance from professionals. Their expertise can provide valuable insights and ensure the success of your plumbing endeavor.

See Also

Selecting the Correct Copper Pipe Size: 5 Key Steps

Measuring Copper Pipe Size: Your Ultimate Handbook

Decoding Copper Pipe Dimensions: An Extensive Manual