Choosing the Right Copper Pipe Bender for 3/4 Inch Tubing

Selecting the appropriate tool for bending copper pipes is essential. It's important to ensure that your copper pipe bender 3/4 is compatible with the specific copper pipe diameters you are handling. This choice significantly affects the quality and accuracy of your work. Copper pipes, particularly those with a 3/4 inch diameter, are commonly used in various applications such as plumbing and HVAC systems. There is a variety of benders available, including manual, hydraulic, and electric options, each offering distinct advantages. Additionally, a copper pipe expander tool can be a valuable addition to your toolkit, providing increased versatility for certain projects.

Understanding Copper Pipe Benders

Types of Copper Pipe Benders

When it comes to bending copper pipes, you have several options. Each type of bender offers unique benefits, so it's important to know what suits your needs best.

Manual Benders

Manual benders are the simplest and most affordable option. You operate these tools by hand, which gives you control over the bending process. They're great for small projects or when you need to make quick adjustments. However, they require some physical effort, so keep that in mind if you're planning a big job.

Hydraulic Benders

Hydraulic benders use fluid pressure to bend pipes. These tools are more powerful than manual benders and can handle tougher materials with ease. If you're working on a large-scale project or dealing with thicker pipes, hydraulic benders might be your best bet. They offer precision and require less physical effort, making them a favorite among professionals.

Electric Benders

Electric benders bring automation into the mix. With the push of a button, these machines do the hard work for you. They're perfect for repetitive tasks and can save you a lot of time. If you're in a busy workshop or need to produce consistent bends, electric benders are worth considering. They might be more expensive, but the efficiency they offer can be a game-changer.

Key Features to Consider

Choosing the right bender involves more than just picking a type. You need to consider several key features to ensure you get the best tool for your needs.

Bending Capacity

First, think about the bending capacity. This refers to the maximum size and thickness of the pipe the bender can handle. Make sure the bender you choose can accommodate 3/4 inch tubing. Otherwise, you might end up with a tool that can't do the job.

Portability

Next, consider portability. If you need to move your bender around a lot, look for a lightweight and compact model. Some benders come with carrying cases or handles, making them easier to transport. Portability can be a huge advantage if you're working on multiple sites.

Durability

Finally, don't overlook durability. A good bender should withstand regular use without breaking down. Check the materials and construction quality before making a purchase. Investing in a durable bender can save you money in the long run, as you won't need to replace it frequently.

By understanding these types and features, you can make an informed decision when choosing a copper pipe bender. Whether you're a DIY enthusiast or a professional, the right tool can make all the difference in your projects.

Evaluating Benders for 3/4 Inch Tubing

When you're in the market for a copper pipe bender 3/4, it's crucial to evaluate your options carefully. You want a tool that fits your needs and handles the specific copper pipe diameters you're working with. Let's dive into some product reviews and criteria to help you make an informed choice.

Product Reviews

RIDGID Model 608 Heavy-Duty Tube Bender

The RIDGID Model 608 stands out for its robust construction and ease of use. This heavy-duty tube bender is perfect for those who need to bend 3/4 inch tubing regularly. It offers precision and durability, making it a favorite among professionals. You can rely on this tool to deliver consistent results without much effort. Its design ensures that you get smooth bends every time, which is essential for maintaining the integrity of your copper pipes.

Just Better Tools Maxi Tube Bender Set

If versatility is what you seek, the Just Better Tools Maxi Tube Bender Set might be your best bet. This set accommodates multiple copper pipe diameters, including 3/4 inch. It's an excellent choice for those who work with various sizes and need a reliable tool for each. The set's ergonomic design makes it easy to handle, reducing fatigue during long projects. You can achieve precise bends up to 90 degrees, ensuring your work meets high standards.

Spring Benders for 3/4 Inch Copper Pipes

Spring benders offer a simple yet effective solution for bending 3/4 inch copper pipes. These tools are lightweight and portable, making them ideal for quick jobs or when you're on the go. You can easily carry them in your toolkit and use them whenever needed. Spring benders provide a cost-effective option without compromising on quality. They help prevent kinks and ensure smooth bends, which is crucial for maintaining the flow in your pipes.

Criteria for Selection

Choosing the right copper pipe bender 3/4 involves more than just picking a brand. You need to consider several factors to ensure you get the best tool for your needs.

Ease of Use

You want a bender that's easy to operate. Look for tools with ergonomic designs and intuitive controls. A user-friendly bender saves you time and reduces the risk of errors. You should feel comfortable using it, even for extended periods.

Precision and Accuracy

Precision is key when working with copper pipe diameters. Your bender should deliver accurate bends every time. Check for features that enhance precision, such as clear markings and adjustable settings. Accurate bends ensure your pipes fit perfectly, preventing leaks and other issues.

Cost-effectiveness

Finally, consider the cost-effectiveness of your choice. While you don't want to skimp on quality, you also don't need to break the bank. Look for a bender that offers good value for money. Consider the tool's durability and versatility, as these factors contribute to its overall worth. Investing in a quality bender can save you money in the long run by reducing the need for replacements or repairs.

By evaluating these products and criteria, you can find the perfect copper pipe bender 3/4 for your projects. Whether you're a DIY enthusiast or a seasoned professional, the right tool makes all the difference.

Best Practices for Using Copper Pipe Benders

When you're working with copper pipe bender, following best practices ensures you get the best results. Let's dive into some essential tips to help you make the most of your copper pipe bender 3/4.

Preparation and Setup

Before you start bending, proper preparation and setup are crucial. This step sets the foundation for a successful project.

Safety Measures

Safety should always come first. Wear protective gear like gloves and safety glasses to shield yourself from potential hazards. Ensure your workspace is clean and free from obstructions. A clutter-free area reduces the risk of accidents. Always check your bender for any signs of wear or damage before use. A well-maintained tool is safer and more effective.

Proper Setup Techniques

Setting up your bender correctly is key to achieving precise bends. Secure the bender on a stable surface to prevent movement during operation. Align the copper pipe accurately within the bender's guides. This alignment ensures even pressure distribution, reducing the chance of errors. Double-check all settings and adjustments before you begin bending.

Bending Techniques

Mastering the right bending techniques can make a significant difference in your work quality. Here are some tips to help you achieve smooth and accurate bends.

Avoiding Kinks

Kinks can ruin your copper pipes, so it's important to avoid them. Use a copper pipe expander tool if necessary to ensure the pipe maintains its shape. Apply steady pressure when bending, and avoid sudden movements. This approach helps maintain the integrity of the copper pipe diameters. If you're using a manual bender, take your time and bend gradually.

Achieving Accurate Angles

Precision is key when bending copper pipes. Mark the desired angle on the pipe before you start. This marking acts as a guide, helping you achieve the exact bend you need. Use the bender's angle indicators to ensure accuracy. If your bender doesn't have these indicators, consider using a protractor for reference. Consistent practice will improve your ability to achieve precise angles.

By following these best practices, you can enhance your skills in using a copper pipe bender 3/4. Whether you're a beginner or an experienced professional, these tips will help you produce high-quality work every time.

Choosing the right copper pipe bender is crucial for achieving precise and efficient results. Investing in a quality bender offers numerous benefits, including durability and ease of use. Consider the outlined criteria and best practices to make an informed decision. This guide provides reliable information to help you select the best tool for your needs. Remember, the right bender can significantly enhance your work quality and efficiency.

See Also

Selecting the Optimal Copper Pipe Flaring Tool for 1/2 Pipe

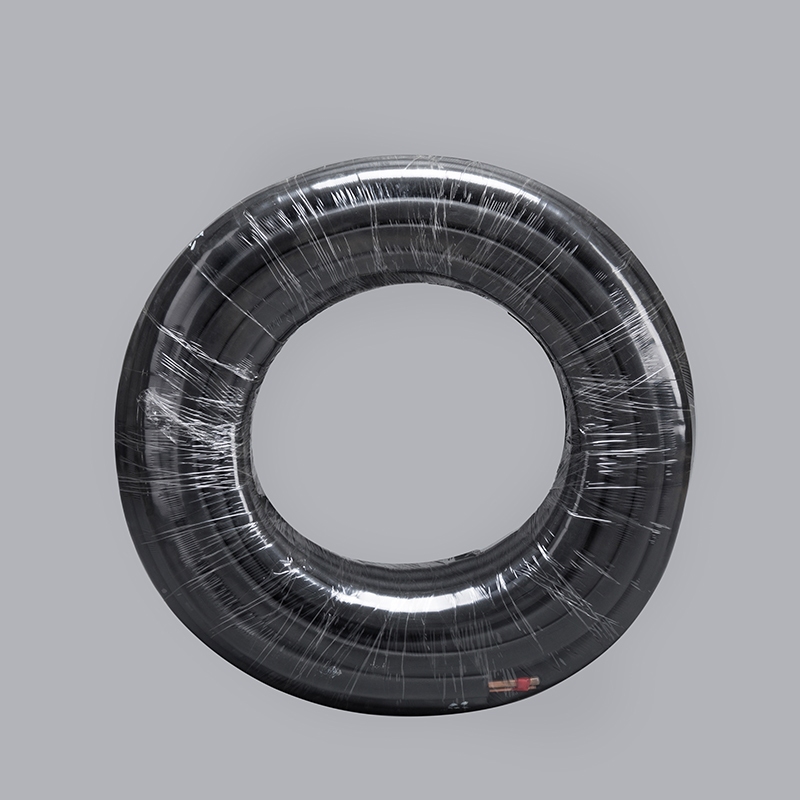

Comprehensive Tips for Choosing 1/4 3/8 Copper Pipe Coils

Key Factors in Selecting the Correct Copper Pipe Diameter

The Definitive Manual for Purchasing 1/4 3/8 Copper Pipe Coils