How to Connect Copper Pipe to PVC - A Step-by-Step Guide

When considering plumbing projects, understanding how do I connect copper pipe to PVC is essential. The seamless integration of these materials ensures durability and efficiency in your system. With various methods available, from threaded connections to compression fittings, choosing the right approach is crucial. This guide aims to simplify the process for you, providing a step-by-step walkthrough for a successful connection. By following this guide, you can confidently tackle your plumbing tasks with ease and precision, including learning how to connect copper to plastic pipe and how to connect PEX to copper.

Tools and Materials

Required Tools

Pipe Cutter

To begin the project, a Pipe Cutter is essential for accurately cutting both the Copper Pipe and PVC Pipe to the required lengths. This tool ensures precise cuts, allowing for a seamless connection between the two materials.

Wrenches

Wrenches play a crucial role in securing the fittings and adapters in place. They provide the necessary torque to tighten connections effectively, ensuring a leak-free joint between the Copper Pipe and PVC Pipe.

Soldering Kit

A Soldering Kit is necessary for creating threaded connections between the copper and PVC pipes. By using this kit, you can securely attach female fittings to the copper pipe and male adapters to the PVC pipe, enabling a durable bond.

Required Materials

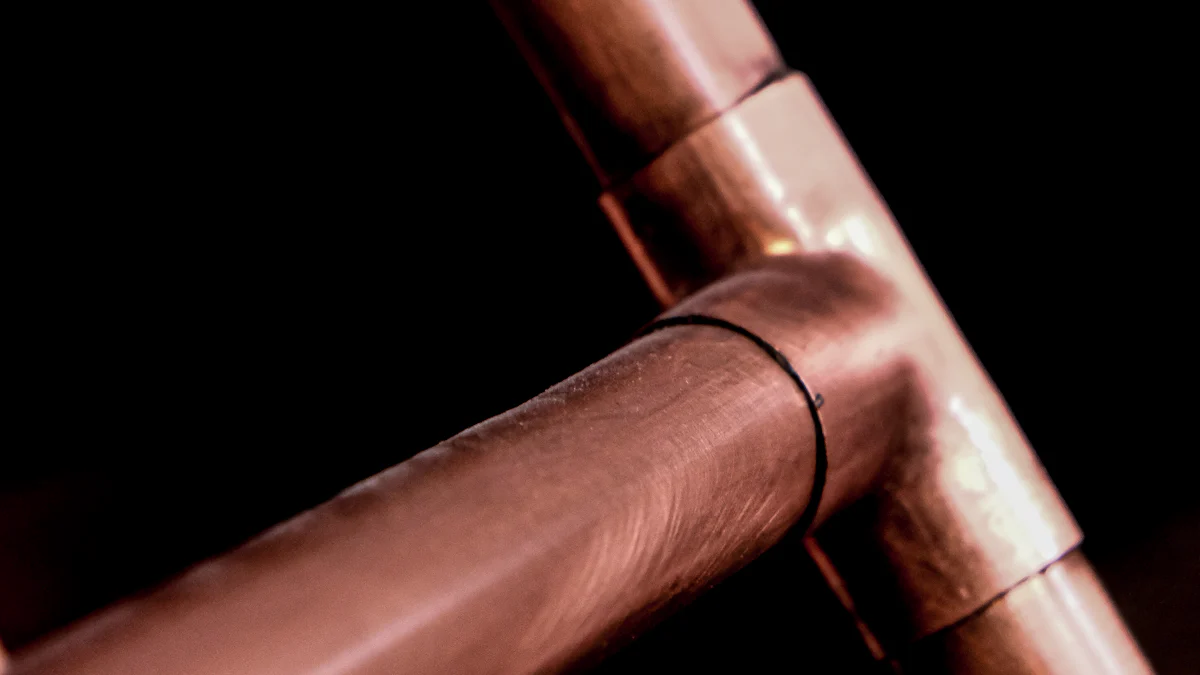

Copper Pipe

The Copper Pipe serves as a reliable material known for its durability and corrosion resistance. When connecting it to PVC, ensure that it is measured and cut precisely to fit seamlessly with the PVC pipe.

PVC Pipe

Utilize a high-quality PVC Pipe, known for its versatility and ease of installation. This material is lightweight yet sturdy, making it an ideal choice for various plumbing applications when connecting it with copper pipes.

Adapters and Fittings

Selecting the appropriate Adapters and Fittings is crucial for creating a secure joint between copper and PVC pipes. These components facilitate different connection methods, such as threaded connections or compression fittings, ensuring a tight seal.

Sealants and Tapes

Using quality Sealants and Tapes is essential to prevent leaks in your plumbing system. Apply these products at connection points to enhance the seal between the copper pipe and PVC pipe, providing added protection against potential leaks.

Preparation

Measuring and Cutting

When preparing to connect copper pipe to PVC, accuracy is key. Measure Copper Pipe precisely to ensure a seamless fit with the PVC counterpart. This step guarantees that the pipes align perfectly, setting the foundation for a secure connection. Next, Measure PVC Pipe accurately to match the dimensions of the copper pipe. This meticulous approach ensures that both pipes complement each other flawlessly. With the measurements in hand, proceed to Cut Pipes to Size with a pipe cutter. By cutting the pipes accurately, you pave the way for a successful connection without any gaps or misalignments.

Cleaning and Deburring

Before joining copper and PVC pipes, cleanliness is crucial for a reliable bond. Start by Cleaning Copper Pipe thoroughly to remove any dirt or debris that could hinder the connection. A clean surface promotes better adhesion between materials, ensuring a leak-free joint. Similarly, Clean PVC Pipe meticulously to eliminate any contaminants that might compromise the connection's integrity. Once both pipes are clean and ready, focus on Deburring Pipe Ends using appropriate tools. Removing burrs from the pipe ends prevents obstructions during assembly and guarantees a smooth transition between copper and PVC.

Connection Methods

Threaded Connections

When soldering female fitting to copper, it is crucial to ensure a clean and secure joint. Begin by heating the fitting with a soldering iron until it reaches the appropriate temperature for solder application. Apply flux to both the fitting and the copper pipe, then carefully introduce the solder to create a strong bond. Once cooled, verify the connection's integrity by conducting a pressure test.

For screwing male adapter to PVC, start by wrapping plumber's tape around the male threads of the adapter in a clockwise direction. This step helps prevent leaks and ensures a tight seal between the PVC pipe and the adapter. Using wrenches, gently tighten the male adapter into place, being cautious not to overtighten and risk damaging the threads. Confirm that the connection is secure before proceeding.

To join both pipes seamlessly, align them correctly while ensuring that both ends are clean and deburred. Insert the male end of the PVC pipe into the female copper fitting, applying gentle pressure until they fit snugly together. Use wrenches to secure any additional fittings or adapters in place, guaranteeing a leak-free connection between copper and PVC.

Compression Fittings

When installing compression ring, slide it onto either end of your pipes before connecting them together. The compression ring plays a vital role in creating a watertight seal between materials of different compositions. Position it carefully to avoid any misalignment that could compromise its effectiveness.

To tighten compression nut, use wrenches to adjust it gradually until you feel resistance indicating a secure fit. Avoid overtightening as this may damage the components or lead to leaks in your plumbing system. Conduct a thorough inspection post-installation to confirm that all connections are properly secured.

Before finalizing your work, always remember to check for leaks after completing all connections using compression fittings. Turn on water flow gradually and inspect each joint for any signs of leakage. Address any issues promptly by adjusting fittings or tightening connections further as needed.

Push-to-Connect Fittings

When inserting copper pipe into push-to-connect fittings, ensure that you push it straight into position without twisting or angling it during installation. This method provides an efficient way of joining copper pipes with other materials like PVC securely.

For inserting PVC pipe into push-to-connect fittings, follow similar guidelines by pushing it straight into place without applying excessive force or causing misalignment with other components. Confirm that both pipes are securely fitted within their respective connectors before proceeding with your plumbing project.

To guarantee an ensure secure fit, conduct a visual inspection of all connections once assembled entirely using push-to-connect fittings. Verify that each joint is tightly sealed without any gaps or signs of potential leakage, ensuring long-lasting performance from your integrated copper and PVC piping system.

Recapping the essential steps outlined in this guide ensures a seamless connection between copper and PVC pipes. The importance of secure connections cannot be overstated, as they guarantee durability and efficiency in your plumbing system. Looking ahead, future maintenance tips include regular inspections for leaks and ensuring all fittings remain tight. By following these guidelines, you can confidently tackle your plumbing projects with ease and precision, creating a reliable integrated piping system that stands the test of time.

Testimonials:

PVC pipes are used in a wide range of applications, such as agriculture, industry, housing, electricity, etc., causing the statistics we see to be very fragmented. It isn’t easy to have a general understanding of this industry.

See Also

Beginner's Guide: Soldering Copper Pipes Made Easy

Comprehensive Manual for Purchasing Copper Pipe Coils

Quick Fix: Repairing a Split Copper Pipe Yourself