Demystifying Copper Pipe Sizes: A Comprehensive Guide

Understanding 1/4 copper pipe, 1/2 copper pipe od, 1/4 in copper pipe, 2 1/2 copper pipe, and 3/8 in copper pipe sizes is essential for efficient plumbing and HVAC systems. Different sizes, such as 1/4 in, 2 1/2, and 3/8 in copper pipes, serve specific purposes based on their dimensions. This guide provides a comprehensive overview of these sizes and their applications, aiding readers in making informed decisions for their projects. By delving into the nuances of each size, individuals can optimize their installations for better performance and cost-effectiveness.

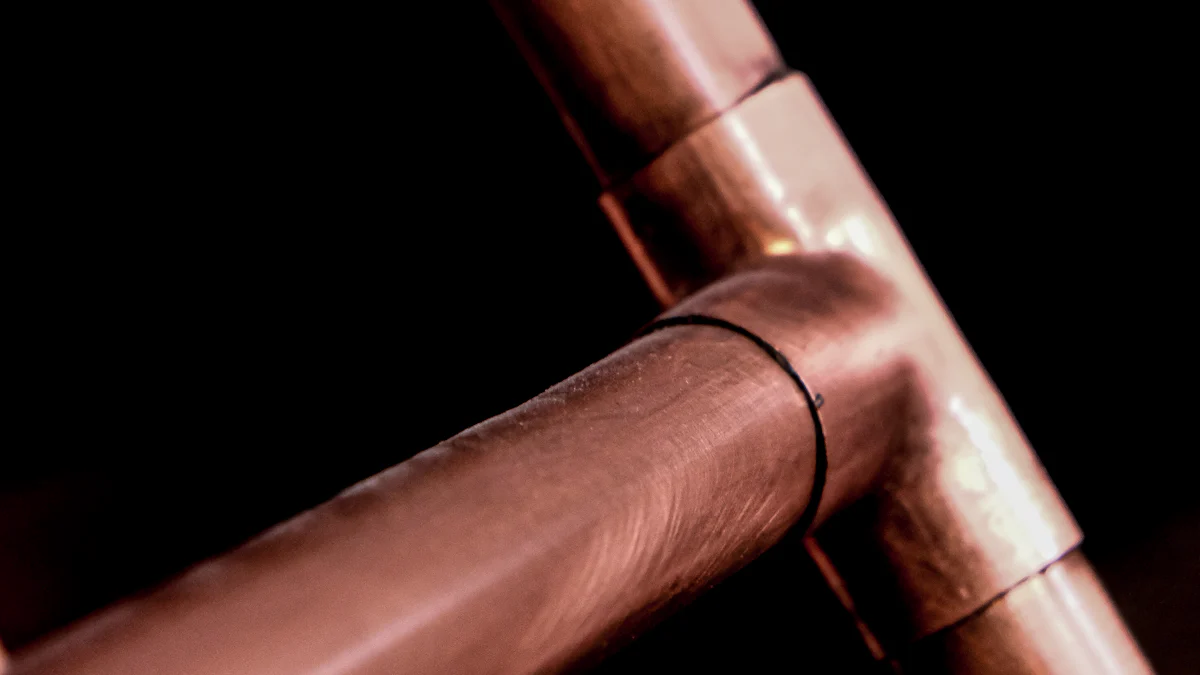

Understanding Copper Pipe Sizes

When it comes to plumbing and HVAC projects, the importance of pipe sizes cannot be overstated. The impact on plumbing projects is significant as it directly influences water flow and pressure within a system. Properly sized pipes ensure efficient water distribution, preventing issues like low pressure or blockages. Similarly, in HVAC projects, the impact of pipe sizes is crucial for maintaining optimal airflow and refrigerant circulation. Choosing the right size can enhance system performance and energy efficiency.

Exploring common copper pipe sizes provides insight into their specific roles. An overview of sizes reveals a range from smaller diameters like 1/4 inch to larger ones such as 2 1/2 inches. Each size caters to distinct requirements based on the volume and speed of fluid needed in a particular application. Understanding these variations allows for precise selection according to project demands.

The applications of each size further illustrate their versatility. Smaller pipes like 1/4 inch are ideal for compact spaces or minor installations where minimal flow is required. On the other hand, larger pipes such as 2 1/2 inches accommodate substantial volumes, making them suitable for industrial settings or high-demand systems. By matching the pipe size to the project scope, individuals can optimize functionality and avoid inefficiencies.

1/4 Copper Pipe

Dimensions and Specifications

Outer Diameter

When considering 1/4 copper pipe, it's essential to note that its outer diameter measures 1/4 inch. This diameter is suitable for specific applications where space is limited, requiring a compact yet efficient plumbing solution.

Wall Thickness

The wall thickness of a 1/4 in copper pipe is designed to complement its outer diameter effectively. Understanding this dimension ensures the durability and reliability of the pipe, especially in small-scale projects or confined spaces.

Common Uses

Small Projects

1/4 copper pipes are commonly utilized in various small projects, such as DIY home repairs or minor plumbing installations. Their compact size and manageable flow capacity make them ideal for tasks that do not demand high volumes of water.

Space-Limited Applications

In scenarios where space constraints are a concern, 1/4 in copper pipes shine due to their ability to navigate tight areas with ease. Whether it's installing a new faucet or repairing a small leak, these pipes offer flexibility and efficiency in confined spaces.

2 1/2 Copper Pipe

Dimensions and Specifications

Outer Diameter

The 2-1/2-inch copper pipe boasts a substantial outer diameter of 2-1/2 inches, making it a robust choice for demanding applications that require high fluid volumes. This diameter ensures efficient flow rates and accommodates the transportation of significant quantities of water or other fluids within plumbing or HVAC systems.

Wall Thickness

The wall thickness of the 2-1/2-inch copper pipe complements its outer diameter, providing durability and structural integrity to withstand the pressures associated with large-scale projects. This thickness ensures the pipe's longevity and reliability in various industrial or commercial settings where resilience is paramount.

Common Uses

Large-Scale Projects

Large-scale projects benefit greatly from the use of a 2-1/2-inch copper pipe due to its capacity to handle substantial fluid volumes effectively. Whether it's industrial facilities, commercial buildings, or extensive plumbing installations, this size excels in ensuring reliable fluid distribution without compromising on performance.

Specific Applications

In addition to general large-scale projects, the 2-1/2-inch copper pipe finds specific applications in scenarios requiring enhanced flow rates and efficiency. Its versatility extends to specialized systems such as high-capacity water supply lines, industrial processing units, or HVAC setups where optimized fluid circulation is essential for operational success.

3/8 in Copper Pipe

Dimensions and Specifications

Outer Diameter

The 3/8 in copper pipe features an outer diameter of 0.5 inches, providing a balance between flow capacity and space efficiency. This diameter ensures optimal fluid circulation while accommodating installations in constrained areas without compromising performance.

Wall Thickness

With a carefully designed wall thickness, the 3/8 in copper pipe guarantees durability and structural integrity for long-term usage. The thickness complements the outer diameter, reinforcing the pipe's ability to withstand varying pressures and maintain consistent functionality.

Common Uses

Water Supply Lines

3/8 in copper pipes are commonly employed in water supply lines due to their versatile nature. These pipes efficiently transport water to different fixtures, ensuring a steady flow rate for residential or commercial applications. Their reliable performance makes them a preferred choice for maintaining consistent water distribution.

Refrigerant Lines

In HVAC systems, 3/8 in copper pipes serve as essential components of refrigerant lines, facilitating the smooth circulation of refrigerants. The precise dimensions of these pipes allow for efficient cooling processes, contributing to the overall effectiveness of air conditioning and refrigeration units. By utilizing these pipes, HVAC systems can achieve optimal performance levels.

Choosing the Right Copper Pipe

Factors to Consider

Plumbers and HVAC professionals face a critical task when selecting the appropriate copper pipe for their projects. Understanding how to interpret and apply the Copper Pipe Diameter Chart empowers them to make informed decisions based on project requirements. By relying on the overview of essential sizes like 1/2 inch, 3/4 inch, and 1 inch copper pipes, these experts ensure efficient installations that meet industry standards.

In larger plumbing systems or commercial applications, the 1-inch copper pipe plays a crucial role in maintaining consistent water pressure and flow rates. Its diameter allows for optimal fluid distribution, ensuring that water reaches its destination efficiently without compromising performance. Plumbers recognize the significance of this size in sustaining reliable operations within complex systems.

Benefits of Correct Pipe Selection

The benefits of choosing the right copper pipe extend beyond mere dimensions. Project efficiency is a key consideration, as selecting an appropriately sized pipe enhances overall system performance. By matching the pipe size to specific project requirements, professionals can optimize fluid flow and prevent issues such as blockages or pressure inconsistencies.

Moreover, cost-effectiveness is another advantage of correct pipe selection. When plumbers choose pipes that align with project needs, they reduce unnecessary expenses associated with resizing or retrofitting later on. The initial investment in selecting the right copper pipe size translates into long-term savings by minimizing maintenance costs and ensuring system longevity.

To ensure efficient installations, plumbers rely on the overview of essential sizes like 1/2 inch, 3/4 inch, and 1 inch copper pipes.

A 1/2-inch diameter is commonly used in residential plumbing projects for connecting fixtures such as sinks and showers.

Monitoring water content and pressure is crucial to prolong the lifespan of copper pipes.

Remember, piping should be structured like a tree; a larger pipe reduces pressure loss and enhances water pressure at fixtures.

See Also

The Indispensable Manual: Measuring Copper Pipe Dimensions

Key Copper Pipe Sizes Every Plumber Must Understand

Becoming Proficient in Copper Pipe Connectors: An In-Depth Handbook

The Definitive Handbook on Copper Pipe Varieties and Soldering Techniques