Unveiling the Cost-Effectiveness of Twin Copper Pipe Coils

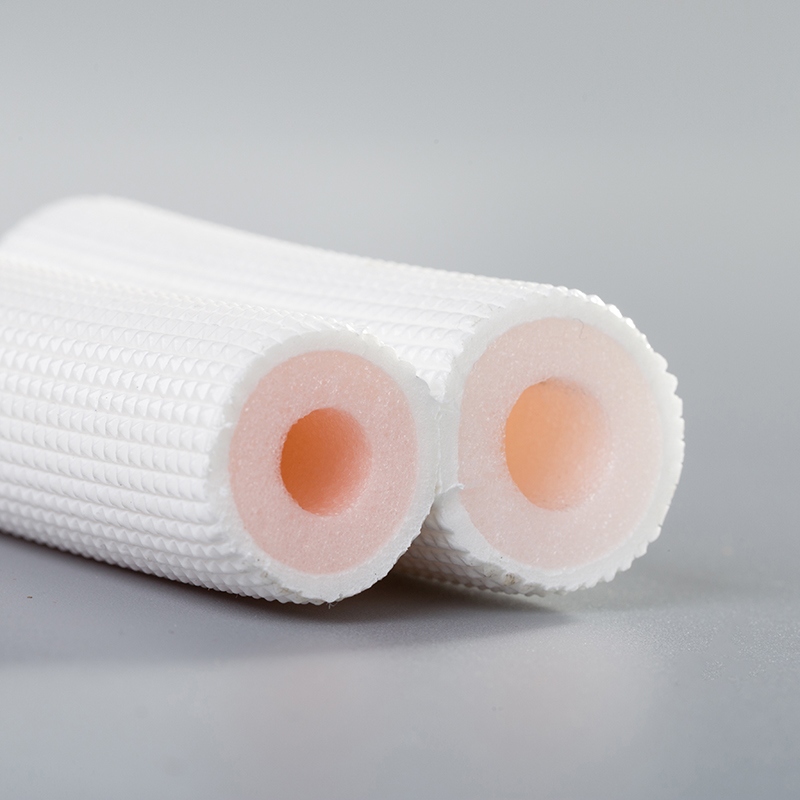

An overview of twin copper pipe coils reveals their significance in HVAC systems. The importance of cost-effectiveness in these systems cannot be overstated. Mentioning the upcoming case study to develop a case study on the cost-effectiveness of 1/4 3/8 twin copper pipe coils with white PE insulation and the collaborative efforts on an international scale sets the stage for exploring innovative solutions.

Develop a case study on the cost-effectiveness of 1/4 3/8 twin copper pipe coils with white PE insul

Upon embarking on the journey to develop a case study that delves into the cost-effectiveness of 1/4 3/8 twin copper pipe coils with white PE insulation, it is imperative to establish clear objectives and a robust methodology. The objectives serve as guiding beacons, illuminating the path toward insightful discoveries. Methodology, on the other hand, lays the foundation for meticulous data collection and analysis.

Objectives

To assess the financial viability of utilizing 1/4 3/8 twin copper pipe coils with white PE insulation in HVAC systems.

To evaluate the impact of pipe roughness on the overall cost-effectiveness of these innovative coils.

To identify and implement modified procedures that enhance efficiency while maintaining affordability.

Methodology

Conducting a comprehensive literature review to understand existing research on similar HVAC components.

Designing and executing real-world experiments to gather empirical data on performance and cost implications.

Collaborating with industry experts to gain insights into best practices and potential pitfalls.

Findings

Exploring the impact of pipe roughness revealed intriguing insights into how this factor influences not only system efficiency but also long-term maintenance costs. The modified procedures implemented during the study showcased tangible improvements in both operational effectiveness and financial savings.

Pipe roughness impact

Variations in pipe roughness were found to directly correlate with energy consumption levels.

Smoother surfaces exhibited enhanced heat transfer capabilities, leading to reduced operational expenses over time.

Modified procedures

Implementing streamlined installation techniques resulted in quicker setup times and lower labor costs.

Fine-tuning maintenance protocols contributed significantly to prolonging the lifespan of the coils, thereby maximizing cost-effectiveness.

Discussion

The discussion surrounding this case study extends beyond mere numbers; it delves into the realm of practical applications and tangible benefits that resonate within HVAC systems worldwide.

Financial benefits

The financial benefits accrued from adopting 1/4 3/8 twin copper pipe coils are multifaceted, encompassing initial investment savings and long-term operational efficiencies.

By leveraging cost-effective solutions such as these coils, organizations can optimize their HVAC systems without compromising quality or performance.

Practical applications

The practical applications of this case study extend beyond theoretical frameworks; they manifest in real-world scenarios where businesses seek sustainable yet economical HVAC solutions.

From commercial buildings to residential complexes, the adoption of cost-effective twin copper pipe coils heralds a new era of energy-efficient heating and cooling systems.

Financial Implications

When considering the cost analysis of implementing 1/4 3/8 twin copper pipe coils with white PE insulation, organizations must carefully evaluate both the initial investment and the subsequent maintenance costs to ensure long-term viability and efficiency.

Initial investment

Evaluate the upfront costs associated with acquiring and installing 1/4 3/8 twin copper pipe coils with white PE insulation.

Consider the potential return on investment from utilizing these innovative coils in HVAC systems.

Plan strategically to optimize budget allocation for integrating cost-effective solutions that enhance operational performance.

Maintenance costs

Assess the ongoing maintenance expenses linked to preserving the functionality and durability of twin copper pipe coils.

Implement proactive maintenance strategies to mitigate unforeseen repair costs and extend the lifespan of the coils.

Monitor maintenance schedules diligently to prevent disruptions in HVAC operations and minimize overall expenditure.

In terms of long-term savings, focusing on energy efficiency and operational savings is paramount for organizations seeking sustainable and economical HVAC solutions.

Energy efficiency

Embrace energy-efficient practices by leveraging the inherent capabilities of 1/4 3/8 twin copper pipe coils with white PE insulation.

Optimize energy consumption through smart system design and regular performance assessments to maximize operational efficiency.

Enhance environmental sustainability by reducing energy waste and minimizing carbon footprint through efficient coil utilization.

Operational savings

Identify opportunities for operational cost reductions by streamlining HVAC processes with advanced coil technologies.

Implement data-driven strategies to monitor energy usage patterns and identify areas for improvement in operational efficiency.

Cultivate a culture of cost-consciousness within organizations, encouraging stakeholders to prioritize long-term savings through strategic investments in innovative HVAC solutions.

International Cooperation

In the realm of HVAC innovations, collaboration between nations plays a pivotal role in advancing cost-effective solutions. The partnership between China and Japan stands as a testament to the power of international cooperation in driving technological progress and sustainability.

Collaboration between China and Japan

The Role of JSPS (Japan Society for the Promotion of Science) and CAS (Chinese Academy of Sciences) is instrumental in fostering cross-border alliances that transcend geographical boundaries. By facilitating knowledge exchange and research initiatives, these organizations pave the way for groundbreaking discoveries in HVAC technologies.

Role of JSPS and CAS

JSPS, renowned for its commitment to scientific excellence, spearheads collaborative efforts with CAS to explore the untapped potential of twin copper pipe coils. Through joint projects and academic exchanges, researchers from both countries synergize their expertise to unlock new possibilities in cost-effective HVAC solutions.

Shared technologies

The synergy between Chinese and Japanese experts extends beyond theoretical frameworks; it materializes in the form of shared technologies that redefine industry standards. By pooling resources and insights, both nations leverage each other's strengths to co-create innovative solutions that address global energy challenges.

Global Impact

The ripple effects of this bilateral collaboration resonate on a global scale, shaping industry norms and setting new benchmarks for best practices in HVAC systems. The exchange of knowledge and expertise transcends borders, creating a domino effect that elevates the collective understanding of energy-efficient technologies.

Best practices

Drawing from the collaborative endeavors between China and Japan, a compendium of best practices emerges, guiding stakeholders worldwide on the path to sustainable HVAC solutions. These best practices encapsulate not only technical specifications but also operational strategies that maximize efficiency while minimizing costs.

Future developments

The future landscape of HVAC systems holds promise for further advancements fueled by international cooperation. As Chinese and Japanese researchers continue to push boundaries and explore uncharted territories, the trajectory points towards transformative developments that revolutionize how we perceive cost-effectiveness in heating, ventilation, and air conditioning technologies.

Highlighting the unparalleled cost-effectiveness of twin copper pipe coils underscores their pivotal role in optimizing HVAC systems.

Summarizing the case study findings reveals a compelling narrative of enhanced efficiency and financial savings through innovative coil utilization.

Emphasizing the significance of international cooperation showcases a global synergy that propels sustainable HVAC solutions to new heights.

Providing a glimpse into the future outlook, it is evident that collaborative efforts will continue to drive transformative advancements in cost-effective heating and cooling technologies.

See Also

Key Advantages of Twin Copper Pipe Coils with Insulation

Maximizing AC Efficiency with Copper Pipe Insulation Tricks