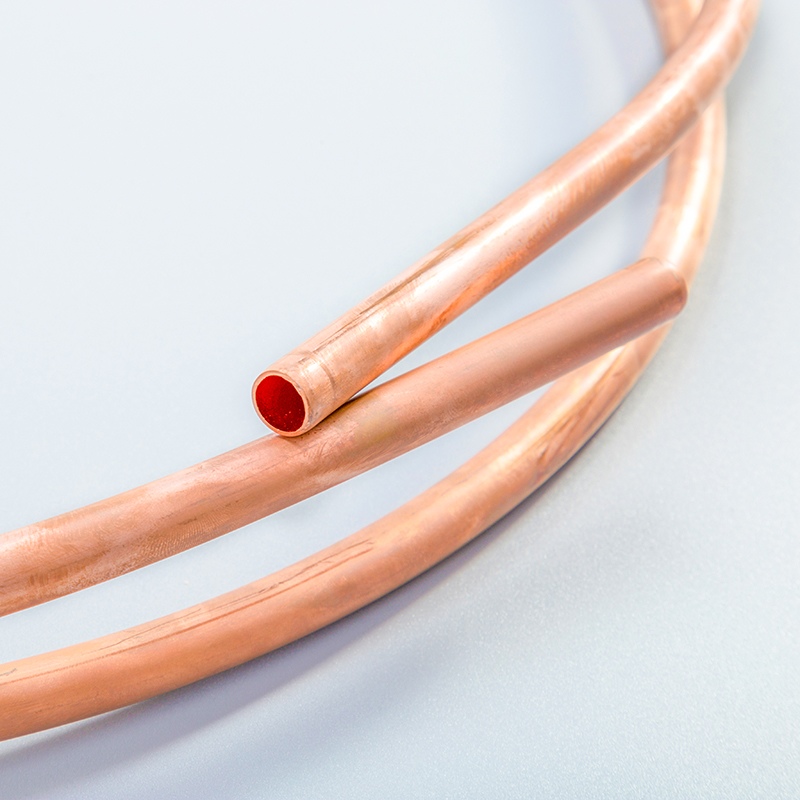

How to Cut Copper Pipes in Tight Spaces: A Step-by-Step Guide

Facing the challenge of cutting copper pipe in tight spaces is a common hurdle for both professionals and DIY enthusiasts. The precision required for this task often leads to issues like uneven cuts, misalignment, and burrs. To overcome these obstacles, it's crucial to master the techniques and tools involved in cutting copper pipe in tight spaces. This comprehensive guide will equip you with the necessary knowledge from preparation to finishing touches, ensuring your plumbing projects are leak-free and successful. Additionally, understanding copper water pipe sizes and how to deburr copper pipe using a deburring tool cop will further enhance the quality and efficiency of your work.

Tools and Preparation

Necessary Tools

When it comes to cutting copper pipes in tight spaces, having the right tools is essential for a successful job. Here are the necessary tools you should have on hand:

Compact Tubing Cutter

Superior Tool's® Large Capacity 1-1/8" O.D. Mini Tubing Cutter: This compact tool is a workhorse preferred by professionals in various fields. Its specially designed structure allows it to fit into tight spaces on larger diameter tubing, ensuring precise cuts.

Imperial 174-F 3/8″ to 1-1/8″ Compact Tube Cutter: With a spare cutting wheel included, this tool provides versatility and efficiency when working with copper pipes.

Mini Hacksaw

A versatile cutting tool suitable for cutting copper tubing in tight spaces or when a tubing cutter is unavailable.

Rotary Tool

Consider using a rotary tool with a metal-cutting blade for better accessibility when cutting copper pipes in confined areas.

Safety Gear

Prioritize safety while working with copper pipes by wearing the following safety gear:

Gloves

Protect your hands with gloves to prevent injuries while handling sharp tools and materials.

Goggles

Safeguard your eyes with goggles to shield them from any debris that may arise during the cutting process.

Copper Water Pipe Sizes

Understanding copper water pipe sizes is crucial for selecting the right materials for your project. Here are some common sizes you may encounter:

Common Sizes

Various diameters of copper pipes are available, ranging from small to large, to accommodate different plumbing needs.

Choosing the Right Size

Selecting the appropriate size of copper pipe ensures optimal water flow and pressure within your plumbing system.

Cutting Process

Cutting Copper Pipe in Tight Spaces

To begin cutting copper pipe in tight spaces, position your chosen cutting tool for the task. Ensure a steady grip on the tool to maintain precision throughout the cutting process.

Using a Compact Tubing Cutter

Start by aligning the compact tubing cutter with the copper pipe's surface. Apply gentle pressure as you rotate the cutter around the pipe, gradually deepening the incision with each turn. Continue this method until you achieve a clean and precise cut.

Using a Mini Hacksaw

When utilizing a mini hacksaw, carefully guide the blade along the marked cutting line on the copper pipe. Employ smooth and controlled strokes to avoid unnecessary vibrations that may lead to uneven cuts or jagged edges. Remember to maintain a steady hand for optimal results.

Using a Rotary Tool

Opting for a rotary tool equipped with a metal-cutting blade offers versatility in cutting copper pipes in tight spaces. With its high-speed rotation, this tool swiftly slices through the copper material, allowing for efficient and accurate cuts. Exercise caution and control when using this power tool to ensure safety and precision.

Manipulating the Pipe

After making the initial cut, it's essential to manipulate the pipe for further adjustments and accessibility within confined spaces.

Creating Flex

To create flexibility in the copper pipe post-cutting, gently manipulate it by applying light pressure in strategic areas. This flex will facilitate easier maneuverability when positioning or adjusting the pipe during installation or repairs.

Pulling Pipe Forward

For enhanced accessibility during cutting copper pipes in tight spaces, consider pulling the pipe slightly forward from its original position. This slight movement creates additional room for maneuvering your cutting tools effectively, ensuring accurate cuts without constraints.

Using a Pipe Cutter

When traditional cutting methods are not feasible due to space limitations, specialized pipe cutters offer practical solutions for precise cuts within confined areas.

Handleless Pipe Cutter

Employing a handleless pipe cutter allows you to navigate tight spaces with ease while maintaining control over your cutting actions. The compact design of this tool enables seamless operation even in challenging environments, ensuring efficient results.

Dremel Tool

In scenarios where conventional tools fall short, utilizing a Dremel tool with a metal blade provides an alternative approach to cutting copper pipes effectively. The precision and agility of this tool enable intricate cuts in restricted spaces, offering versatility and accuracy for your plumbing projects.

Finishing Touches

Deburr Copper Pipe

To achieve a professional finish when working with copper pipes, it is essential to deburr the copper pipe after cutting. This process involves removing any rough edges or burrs left on the pipe to ensure a smooth and clean surface for optimal functionality.

Using a Deburring Tool Cop

When deburring copper pipe, employing a high-quality deburring tool such as the Ridgid 35155 Model E-4546 can streamline the process. This tool features precision-ground cutting edges that efficiently remove burrs from the inside and outside of the pipe, resulting in a polished finish. By utilizing this tool correctly, you can enhance the overall appearance of your plumbing project while maintaining the integrity of the copper pipe.

Ensuring Smooth Edges

After deburring the copper pipe, it is crucial to inspect the edges for any remaining imperfections. Run your fingers along the cut area to check for smoothness and consistency. Any rough spots should be addressed promptly to prevent potential leaks or disruptions in water flow. By ensuring that the edges are smooth and free of burrs, you can guarantee a secure and reliable connection for your plumbing system.

Final Adjustments

Once you have deburred and inspected the copper pipe, it's time to make final adjustments before proceeding with installation or soldering.

Checking the Fit

Before finalizing your project, verify that the cut copper pipe fits seamlessly into its designated location. Ensure that there are no gaps or misalignments that could compromise the integrity of your plumbing system. Making necessary adjustments at this stage will save you time and effort during installation, preventing potential issues down the line.

Preparing for Soldering

If soldering is required for your plumbing project, take this opportunity to prepare the cut copper pipe accordingly. Clean both ends of the pipe thoroughly using a wire brush or emery cloth to remove any debris or oxidation. Properly preparing the surfaces will promote strong adhesion during soldering, ensuring a watertight seal for your connections.

Mastering the skill of cutting copper pipe is essential for any plumbing or DIY project.

By following the steps outlined in this comprehensive guide and utilizing the appropriate cutting method, you can achieve accurate and clean cuts with ease.

Remember to prioritize safety by wearing protective gear and using the right tools.

With practice and attention to detail, you’ll become proficient in cutting copper pipe, ensuring the success of your plumbing projects.

See Also

Effortless Process: Measuring Copper Pipe for DIY Achievement

Key Guidelines for Dealing with Unusual 1/2' Copper Pipes

Basic Guide: Soldering a Copper Pipe for Novices

Simple Manual: Measuring Copper Pipe Like an Expert

Effortless Process for Measuring Copper Pipes Like an Expert