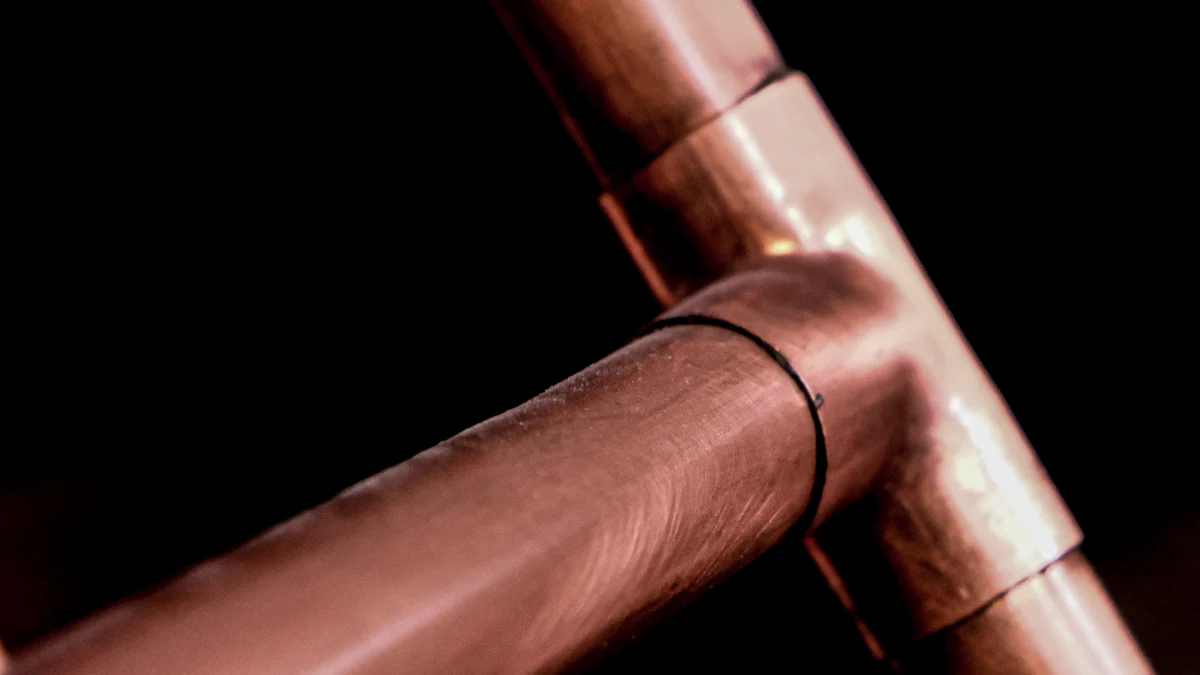

Steps to Ream Copper Pipes Effectively: A Complete Guide

Steps to ream copper pipes effectively

Properly reaming copper pipes is essential in the plumbing process to ensure a secure and long-lasting connection. By reaming the pipe, it creates a smooth surface that allows water to flow efficiently and guarantees a perfect fit into the fitting cup. Neglecting this step can lead to issues such as corrosion and jeopardize the pipe's durability. It is crucial to remove any burrs inside the pipe after cutting to maintain optimal water flow. This guide will delve into the significance of reaming copper pipes, provide an overview of the reaming process, and highlight the benefits of meticulous reaming techniques.

Step-by-Step Guide

Preparation

To begin the reaming process effectively, it is essential to first gather the necessary tools. A Pipe Reamer can be a valuable asset in deburring steel pipes before threading, ensuring optimal water flow and longevity of the connection. This tool features a unique cutting edge that makes the reaming process self-feeding and easy to operate. Additionally, utilizing a Reaming Tool post-cutting is crucial for removing any small burrs inside the copper pipe, preventing sediment build-up that could lead to blockages.

When preparing for reaming, measuring and marking the pipe accurately is key. This step ensures precision in cutting and reaming, leading to a seamless fit with the fitting cup. By employing a Deburring Tool or a separate reaming tool, you can consistently turn until the inner surface of the pipe regains its smooth quality, guaranteeing an efficient water flow.

Gather Tools:

Pipe Reamer: Ensures proper deburring of steel pipes before threading.

Reaming Tool: Essential for removing burrs inside copper pipes post-cutting.

Measure and Mark:

Accurately measure and mark the pipe for precise cutting and reaming.

Utilize a Deburring Tool or separate reaming tool for consistent turning until inner surface smoothness is achieved.

Cutting the Pipe

When it comes to cutting the pipe, using a reliable Pipe Cutter is paramount for achieving clean cuts without deformations. After cutting, it's crucial to remove any burrs present on both the inside and outside of the pipe to ensure a secure fit into the fitting cup. Properly utilizing a manual Pipe Reamer tool can significantly reduce work time while delivering optimal results in pipe reaming.

Use a Pipe Cutter:

Employ a high-quality Pipe Cutter for clean and precise cuts.

Ensure no deformations occur during cutting process.

Remove Burrs:

Eliminate any burrs on both inside and outside of cut pipe.

Opt for manual Pipe Reamer tool for efficient results in deburring process.

Cleaning and Final Steps

To ensure the integrity of the copper pipe installation, the cleaning and final steps play a crucial role in guaranteeing a secure and leak-free connection. Cleaning the pipe and joint is essential to remove any debris or contaminants that could compromise the fitting. This process involves using a suitable cleaning solution to wipe down both surfaces thoroughly, ensuring optimal adhesion during the assembly.

Inspecting the work after cleaning is imperative to verify that all steps have been executed correctly. By meticulously examining the pipe and joint, any overlooked imperfections can be identified and rectified promptly. This inspection serves as a quality control measure to confirm that the reaming process has been completed effectively, setting the stage for successful installation.

Clean the Pipe and Joint:

Utilize a suitable cleaning solution to wipe down both pipe and joint surfaces.

Ensure thorough removal of debris or contaminants for optimal adhesion.

Inspect the Work:

Meticulously examine both pipe and joint for any imperfections.

Identify and rectify any overlooked issues promptly for quality control.

Tips for Effective Reaming

Tool Maintenance

Maintaining sharp tools is essential for effective reaming of copper pipes. A dull tool can lead to uneven surfaces and hinder the proper fit of the pipe into the fitting cup. By ensuring that tools are sharp, the reaming process becomes smoother and more precise, resulting in a secure connection that minimizes the risk of leaks or malfunctions.

Keep Tools Sharp

Regularly sharpening tools like deburring tools and pipe reamers is crucial.

A sharp tool guarantees a clean cut and smooth surface for optimal water flow.

Dull tools can cause rough edges, affecting the overall integrity of the connection.

Regular Cleaning

After each use, thoroughly clean all reaming tools to prevent debris buildup.

Cleaning ensures that the tools remain efficient and ready for future projects.

Proper maintenance prolongs the lifespan of the tools, saving time and resources in the long run.

Safety Precautions

Prioritizing safety measures during the reaming process is paramount to prevent accidents and ensure a successful outcome. Protective gear shields individuals from potential hazards, while working in a well-ventilated area promotes a healthy environment free from harmful fumes or dust particles.

Wear Protective Gear

Always wear safety goggles to protect eyes from metal shavings or debris.

Gloves should be worn to safeguard hands against sharp edges or hot surfaces.

Protective clothing, including long sleeves and pants, adds an extra layer of protection.

Work in a Well-Ventilated Area

Choose a workspace with adequate ventilation to disperse any fumes generated during reaming.

Proper ventilation reduces the risk of inhaling harmful particles or gases released during the process.

Fresh air circulation enhances comfort and promotes overall well-being while working on copper pipe installations.

Common Mistakes to Avoid

When it comes to reaming copper pipes, overlooking certain steps can lead to detrimental consequences in the plumbing process. Each step in the reaming procedure plays a crucial role in ensuring a secure and long-lasting connection. Skipping any of these essential steps can compromise the integrity of the installation and result in potential issues down the line. It is imperative to understand the significance of each step involved in reaming copper pipes to avoid common mistakes that could jeopardize the overall effectiveness of the process.

Importance of Each Step

Every step in reaming copper pipes serves a specific purpose that contributes to the successful completion of the installation. From preparing the pipe for reaming to cleaning and inspecting the final work, each stage is interconnected and vital for achieving optimal results. By acknowledging the importance of each individual step, professionals can ensure that every aspect of reaming is meticulously executed, leading to a flawless connection between pipes and fittings.

Gather Tools: The initial step of gathering tools sets the foundation for a smooth reaming process. Without the proper tools such as a Pipe Reamer and Reaming Tool, achieving a clean and burr-free surface becomes challenging, potentially affecting water flow efficiency.

Measure and Mark: Accurately measuring and marking the pipe guarantees precision during cutting and reaming. This step is fundamental in ensuring that the pipe fits seamlessly into the fitting cup, eliminating any gaps or misalignments.

Use a Pipe Cutter: Utilizing a high-quality Pipe Cutter is essential for clean cuts without deformations. Neglecting this step can result in uneven edges that hinder proper fitting into fittings.

Remove Burrs: Eliminating burrs on both inside and outside surfaces post-cutting is critical for a secure fit. Failure to remove burrs can lead to blockages or leaks within the plumbing system.

Clean Pipes and Joints: Thoroughly cleaning both pipes and joints removes debris that could compromise adhesion. Clean surfaces are essential for ensuring leak-free connections between pipes and fittings.

Inspect Work: Conducting a detailed inspection after cleaning ensures that all steps have been correctly executed. Identifying any imperfections allows for immediate rectification, guaranteeing a flawless reaming process.

By understanding and adhering to each step's significance within the reaming process, professionals can avoid common mistakes that may arise due to oversight or negligence. Prioritizing attention to detail at every stage ensures an efficient installation with minimal room for errors or complications.

Reiterate the importance of meticulous reaming to ensure a secure connection and optimal water flow.

Emphasize the critical role of proper reaming in achieving a leak-free joint during soldering copper pipes.

Encourage adherence to the comprehensive guide for successful installation and long-lasting durability.

By highlighting the significance of each step, professionals can execute flawless reaming processes that guarantee efficient plumbing systems. Remember, attention to detail in reaming is key to impeccable connections and sustained performance. Stay committed to precise preparation for soldering copper pipes, ensuring safety and reliability in every installation project.

See Also

Maximizing Efficiency: The Ultimate Copper Pipe Maintenance Guide

Becoming a Pro: The Complete Copper Pipe Fittings Mastery

Beginner's Guide: Mastering Copper Pipe Soldering in Easy Steps