Your Essential Guide to 3-Inch Copper Pipe Fittings

Copper pipe fittings play a crucial role in plumbing systems, offering durability and corrosion resistance. Among these fittings, 3-inch copper pipe fittings stand out for their versatility and reliability. This guide aims to provide a comprehensive overview of 3-inch copper pipe fittings, shedding light on their uses and benefits. Additionally, 4 copper pipe and 5/8 copper pipe fittings are also essential components in various plumbing applications. By exploring the nuances of these fittings, including the copper pipe cap and copper pipe coupling, readers will gain valuable insights into how they can enhance plumbing systems efficiently.

Types of Copper Pipe Fittings

When it comes to plumbing systems, selecting the right copper pipe fittings is essential for ensuring efficiency and leak-free operations. Among the various types available, 3-inch copper pipe fittings are versatile and reliable components. These fittings offer a comprehensive solution for both residential and commercial plumbing needs. Additionally, 4 copper pipe fittings and 5/8 copper pipe fittings play crucial roles in different applications, providing flexibility and durability.

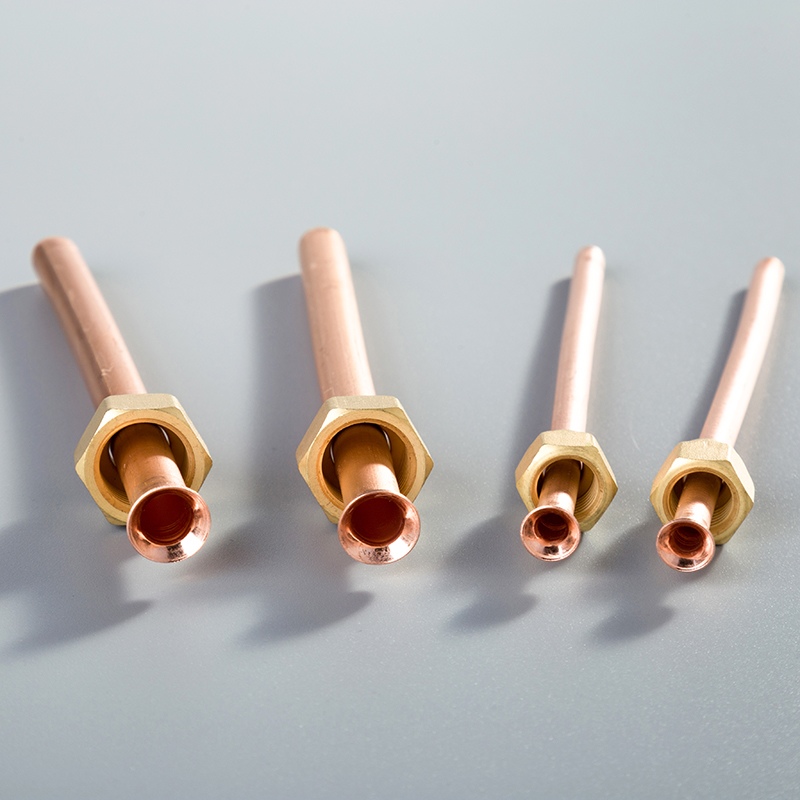

To meet specific requirements in plumbing projects, various types of copper fittings are utilized. These include compression fittings, end feed fittings, solder ring fittings, push fit fittings, and press fittings. Each type serves a unique purpose in joining copper pipes effectively without compromising on quality or performance.

Copper fittings such as tees, elbows, couplings, reducers, and adapters are commonly used in different plumbing applications to ensure seamless connections and optimal flow within the system.

Copper Pipe Cap

Overview:

Copper pipe caps are essential components in plumbing systems, designed to seal the end of a copper pipe permanently. They are commonly used in above-ground potable water supply systems to prevent leaks and ensure the integrity of the pipeline. Copper pipe caps come in various sizes, including 1/4 inch and 3/8 inch, made of durable Wrot copper. These caps are suitable for soldering applications and provide a secure closure for pipes.

Installation Tips:

Ensure the copper pipe cap matches the size of the pipe for a proper fit.

Clean the end of the copper pipe thoroughly before installing the cap to remove any debris or contaminants.

Apply flux to both the inside of the cap and the outside of the pipe to promote solder adhesion.

Heat the joint evenly while soldering to create a strong bond between the cap and the pipe.

Allow sufficient cooling time after soldering before pressurizing the system to avoid damage.

Installation Tips

Preparing the Pipes

Cleaning

To ensure a proper connection and prevent potential leaks, cleaning the pipes is a crucial step in the installation process. Here are some essential steps to follow:

Use a pipe cleaning brush to remove any dirt, debris, or oxidation from the outer surface of the copper pipe.

Apply a small amount of emery cloth or sandpaper to scrub the pipe gently and create a clean surface for soldering.

Wipe down the pipe with a clean cloth to remove any remaining residue before proceeding with the installation.

Measuring

Accurate measurements are key to a successful plumbing project. Follow these steps to measure your pipes correctly:

Use a tape measure or ruler to determine the length of the pipes needed for your project.

Mark the cutting points on the pipes using a pencil or marker for precision.

Double-check your measurements before cutting to avoid any errors that could impact the fit of your copper fittings.

Soldering Techniques

Tools Needed

When it comes to soldering copper pipes, having the right tools is essential for achieving secure and leak-free connections. Here are some tools you'll need:

Soldering Iron: A high-quality soldering iron with adjustable temperature settings is ideal for precise control during soldering.

Flux: Flux helps clean and prepare the surfaces of the copper pipes and fittings for soldering.

Solder Wire: High-quality lead-free solder wire ensures strong and durable connections between copper components.

Pipe Cutter: A pipe cutter allows you to make clean and precise cuts on copper pipes for accurate fitting installations.

Step-by-Step Guide

Follow these steps for successful soldering of copper pipes:

Clean both ends of the pipes thoroughly using emery cloth or sandpaper.

Apply flux to both surfaces that will be joined together.

Heat the joint evenly using a soldering iron until it reaches the appropriate temperature for solder application.

Apply solder around the joint, allowing it to flow smoothly into the connection through capillary action.

Let the joint cool naturally without disturbing it to ensure a solid bond between the pipes.

Safety Precautions

Protective Gear

Prioritize safety by wearing appropriate protective gear during plumbing work:

Safety Glasses: Protect your eyes from debris, flux, and hot metal particles while working on plumbing installations.

Gloves: Wear heat-resistant gloves to shield your hands from burns when handling hot materials like solder and piping.

Ventilation

Maintain proper ventilation in your workspace when soldering copper pipes:

Work in a well-ventilated area or use an exhaust fan to prevent inhaling harmful fumes released during soldering.

Avoid breathing in smoke or fumes by positioning yourself so that they move away from your face while working on plumbing connections.

By following these installation tips and techniques, you can ensure efficient and reliable plumbing systems using 3-inch copper pipe fittings along with other essential components like compression fittings, end caps, and various types of couplings tailored for different applications.

Applications and Benefits

Residential Plumbing

Copper plumbing fittings are a staple in residential plumbing, offering unparalleled durability and efficiency. The durability of copper fittings ensures long-lasting performance in home plumbing systems. These fittings are resistant to corrosion, providing homeowners with peace of mind knowing that their plumbing infrastructure is built to last. In terms of efficiency, copper fittings facilitate optimal water flow within the system, reducing the risk of clogs or leaks that can disrupt daily activities.

Commercial Plumbing

In large-scale commercial projects, copper plumbing fittings play a vital role in ensuring the success and cost-effectiveness of plumbing installations. The robust nature of copper fittings makes them ideal for handling the demands of extensive plumbing systems in commercial buildings. Whether it's a high-rise office complex or a bustling shopping center, copper fittings provide reliable connections that withstand heavy usage and maintain efficiency over time. Additionally, the cost-effectiveness of copper fittings contributes to overall project savings by minimizing maintenance needs and ensuring long-term performance.

DIY Projects

For DIY enthusiasts embarking on custom builds or home improvement projects, copper fittings offer a versatile and user-friendly solution. Custom builds often require specific configurations and precise connections, which can be easily achieved with copper fittings. Their ease of use simplifies the installation process for DIYers, allowing them to create tailored plumbing solutions without extensive professional assistance. Whether it's crafting a unique fixture or enhancing an existing system, copper fittings provide the flexibility and reliability needed for successful DIY endeavors.

Copper pipe fittings, including 3-inch copper pipe fittings, are essential components in plumbing systems due to their durability and corrosion resistance. The versatility of copper fittings makes them suitable for various applications in residential and commercial settings. Moving forward, considering the benefits of copper fittings such as excellent corrosion resistance, durability, and thermal conductivity, it is evident that they will continue to be a preferred choice for professionals in the plumbing industry. As technology advances, the adaptability of compression fittings for copper pipes will play a crucial role in meeting specific requirements across different sectors.

See Also

The Definitive Guide to Premium Copper Pipe Fittings

Top 5 Tips for Utilizing 1/4 Copper Pipe Fittings

The Comprehensive Manual for Choosing 1/4 3/8 Copper Pipe Coils

The Ultimate Handbook for Purchasing 1/4 3/8 Copper Pipe Coils