Essential Tips for Insulating Copper Pipes in AC Units

Tips for insulating copper pipes in residential AC units

Insulating copper pipes in residential AC units is essential for optimal performance. By enhancing energy efficiency, preventing condensation, and extending the unit's lifespan, proper insulation ensures a well-functioning system. This blog will guide you through the logical sequence of preparation, material selection, and installation to help you insulate your copper pipes effectively.

Preparation

Cleaning the Pipes

To initiate the insulation process effectively, cleaning the pipes is a crucial first step. This ensures proper adhesion of the insulation material and enhances its performance.

Why Cleaning is Essential

Removing dirt and grease from the copper pipes prevents any hindrances during insulation.

Clean surfaces promote better contact between the pipes and insulation, maximizing efficiency.

Tools and Materials Needed for Cleaning

Use a soft cloth or sponge to wipe down the pipes.

Mild detergent or cleaning solution to eliminate stubborn residues.

Ensure you have a bucket of water for rinsing off any cleaning agents.

Step-by-Step Cleaning Process

Dampen the cloth with the cleaning solution.

Gently scrub the pipes to remove dirt and grime thoroughly.

Rinse with clean water to ensure all residues are washed away.

Inspecting the Pipes

After cleaning, it's essential to inspect the pipes meticulously to identify any potential issues that could affect the insulation process.

Identifying Potential Issues

Look for signs of corrosion, dents, or leaks on the surface of the copper pipes.

Check for any irregularities that may compromise the integrity of the insulation once applied.

Ensuring Pipes are Dry and Free of Debris

Use a dry cloth to wipe down the pipes after cleaning to remove excess moisture.

Inspect closely to ensure there are no remaining debris or particles on the surface.

Selecting the Appropriate Materials

Types of Insulation Materials

Foam Insulation

Foam insulation is known for its compatibility with copper pipes.

It provides excellent thermal protection and is easy to install.

The material ensures a snug fit around the pipes, minimizing heat loss.

Rubber Insulation

Rubber insulation stands out for its flexibility and durability.

It offers reliable protection against temperature changes.

This type of insulation is suitable for varying pipe diameters.

Fiberglass Insulation

Fiberglass insulation excels in providing thermal resistance.

It is a cost-effective option that offers long-term efficiency.

The material is ideal for insulating pipes in diverse environmental conditions.

Factors to Consider When Choosing Insulation

Climate and Environmental Conditions

Consider the climate where the AC unit operates to select suitable insulation.

Evaluate the environmental conditions to ensure the longevity of the chosen material.

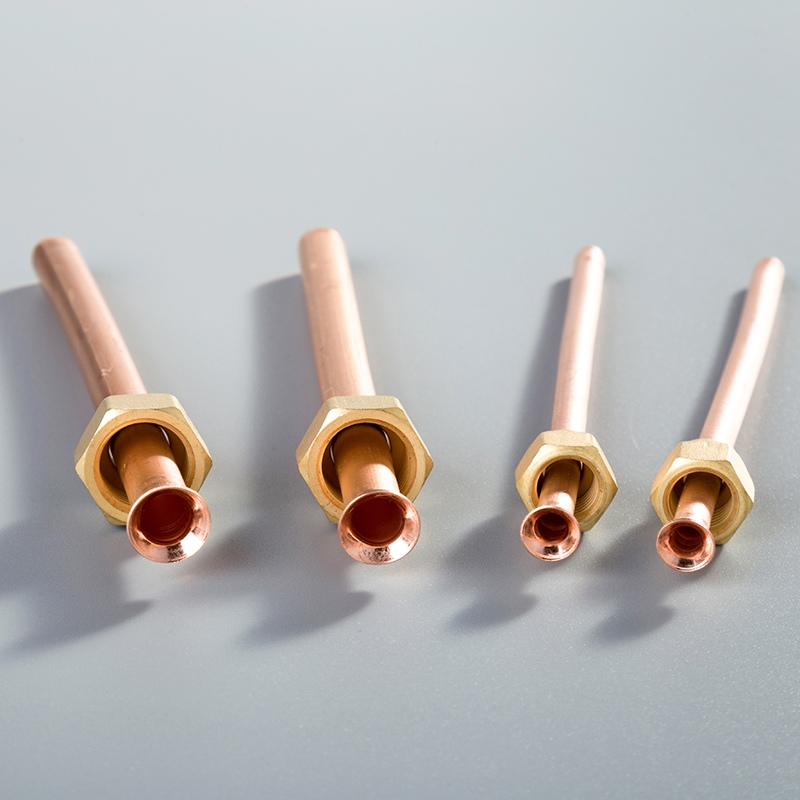

Pipe Diameter and Length

Assess the diameter and length of the copper pipes for precise insulation fitting.

Choose an insulation type that accommodates the specific dimensions effectively.

Budget Considerations

Determine your budget constraints before selecting an insulation material.

Compare different options based on cost-effectiveness and long-term benefits.

Benefits of Each Insulation Type

Energy Efficiency

Each type of insulation contributes to enhancing energy efficiency in AC units.

Foam insulation minimizes heat transfer, reducing energy consumption.

Rubber insulation maintains consistent temperatures, optimizing performance.

Fiberglass insulation provides reliable thermal protection, improving overall efficiency.

Durability

The durability of the selected insulation impacts its long-term effectiveness:

Foam insulation offers lasting protection without deterioration over time.

Rubber insulation withstands temperature variations, ensuring prolonged use.

Fiberglass insulation maintains its structural integrity for extended periods.

Ease of Installation

Simplify your installation process by choosing an appropriate material:

Foam insulation's flexibility allows for easy application on various pipe shapes.

Rubber insulation's adaptability simplifies fitting around bends or curves in pipes.

Fiberglass insulation's lightweight nature facilitates quick and efficient installation.

Installing the Insulation Properly

Measuring and Cutting the Insulation

Tools Required

Sharp utility knife for precise cuts.

Measuring tape to determine the length needed.

Marker for marking the insulation accurately.

Accurate Measurement Techniques

Begin by measuring the length of the pipe.

Mark the insulation material accordingly with a marker.

Use a sharp utility knife to make a clean, straight cut.

Cutting Tips for Different Materials

For foam insulation, ensure a smooth cut without jagged edges.

Rubber insulation may require a slightly angled cut for better fitting.

Fiberglass insulation should be cut with a sharp blade to prevent any fraying.

Applying the Insulation

Wrapping Techniques

Start at one end of the pipe and wrap the insulation in a spiral motion.

Ensure each layer slightly overlaps for complete coverage.

Press down gently to secure the insulation in place.

Securing the Insulation

Use adhesive tape to hold overlapping sections together firmly.

Check for any gaps or loose ends that may need additional securing.

Confirm that the insulation is snug and won't shift easily.

Ensuring a Tight Fit

Double-check that there are no gaps between the pipe and insulation material.

Press along the entire length to guarantee a secure fit.

Test by gently tugging on the insulation to ensure it stays in place securely.

Sealing and Finishing

Using Adhesive Tapes and Sealants

Apply adhesive tape over any exposed seams or joints for added security.

Consider using sealants for extra protection against moisture or air leaks.

Inspecting for Gaps or Loose Areas

Run your hand along the entire length of the insulated pipe to detect any irregularities.

Look closely for gaps, tears, or areas where the insulation might be loose.

Final Touches for a Professional Finish

Trim any excess material neatly with a sharp utility knife for a clean appearance.

2.. Step back and visually inspect your work to ensure all areas are properly covered and sealed off from external elements.

Remember, proper installation of insulation plays a vital role in maximizing energy efficiency and maintaining optimal performance in your AC unit!

Proper insulation is key to enhancing AC unit performance. By following the steps of preparation, material selection, and installation meticulously, homeowners can achieve optimal efficiency and cost savings. A well-insulated system ensures consistent temperatures throughout, leading to lower utility bills and improved comfort levels. Remember, investing time in insulation now can result in long-term benefits for your home's energy consumption and overall climate control.

Testimonials:

Homeowner

"The final product: A sufficiently insulated, air-sealed attic which resulted in fewer drafts, lower utility bills, and even temperatures throughout."

See Also

Enhance Air Conditioner Performance with Copper Pipe Insulation

Exploring Optimal Insulation Solutions for Copper Tubing

Benefits of Selecting Copper Tubing for Air Conditioners