Essential Tips for Maintaining Copper Pipes in Your AC System

Tips for maintaining copper pipes in air conditioning systems

Maintaining copper pipes in AC systems is paramount for ensuring their longevity and efficiency. Well-maintained copper pipes can last anywhere from 25 to 50 years, providing reliable performance throughout. The benefits of regular upkeep extend beyond durability; they guarantee clean and safe water distribution due to copper's exceptional corrosion resistance. In this blog, a series of expert tips will be shared to assist in the proper care and maintenance of copper pipes within air conditioning systems.

Understanding Copper Pipes in AC Systems

Role of Copper Pipes

Copper pipes stand out for their exceptional durability and longevity, ensuring a reliable performance that can last for decades. Their heat transfer efficiency is unmatched, making them the top choice for air conditioning systems.

Heat Transfer Efficiency

The heat transfer efficiency of copper pipes surpasses that of alternative plastic materials commonly used in HVAC systems. This advantage results in better cooling performance and energy efficiency, ultimately leading to cost savings for homeowners.

Durability and Longevity

Compared to other materials in water supply and distribution systems, copper pipes are renowned for their longevity and low maintenance requirements. Their corrosion-resistant properties guarantee clean water delivery without the risk of contamination or leaks.

Common Issues with Copper Pipes

Despite their many benefits, copper pipes are not immune to issues over time. Two common problems that can arise include corrosion and leaks/cracks, which can compromise the integrity of the entire AC system if left unaddressed.

Corrosion

One key difference between copper pipes and alternative plastic materials is their superior resistance to corrosion. Regular inspection and maintenance are essential to detect any signs of corrosion early on and prevent further damage to the system.

Leaks and Cracks

When compared to other materials in HVAC systems, copper pipes are more susceptible to developing leaks or cracks if not properly maintained. Addressing these issues promptly is crucial to avoid water damage and ensure the efficient operation of the air conditioning system.

Regular Inspection and Maintenance

When maintaining copper pipes in air conditioning systems, regular inspection and maintenance are crucial to ensure optimal performance and longevity. By conducting visual inspections, cleaning the copper pipes, and testing various components, you can prevent potential issues and maintain a well-functioning AC system.

Visual Inspection

Checking for Corrosion

To start the inspection process, visually examine the copper pipes for any signs of corrosion. Look for greenish or bluish spots on the surface, indicating oxidation. Addressing corrosion early can prevent further damage to the copper pipes and extend their lifespan.

Identifying Leaks

Another essential aspect of visual inspection is identifying leaks along the copper pipes. Check for any moisture accumulation or water stains near joints or bends. Detecting leaks promptly can help avoid water damage and maintain the efficiency of your air conditioning system.

Cleaning Copper Pipes

Using Appropriate Cleaning Agents

Cleaning plays a significant role in maintaining copper pipes. Choose appropriate cleaning agents that are safe for copper materials to remove dirt and grime effectively. Avoid harsh chemicals that can damage the copper pipes and opt for gentle solutions recommended for copper surfaces.

Steps for Cleaning

Begin by preparing a cleaning solution suitable for copper pipes, such as a mild detergent diluted in water. Use a soft cloth or brush to gently scrub the surface of the copper pipes, focusing on areas with visible dirt or residue. Rinse thoroughly with clean water to ensure no cleaning agent remains on the pipes.

Testing and Monitoring

Checking Water Pressure

Regularly test the water pressure within your AC system to ensure proper flow through the copper pipes. Low water pressure may indicate blockages or leaks that need attention. Monitoring water pressure helps identify issues early and prevents potential disruptions in your cooling system.

Inspecting Fittings and Supports

In addition to inspecting the copper pipes themselves, pay close attention to fittings and supports along the pipeline. Loose connections or damaged supports can lead to stress on the pipes, causing leaks or cracks over time. Tighten fittings as needed and replace any damaged supports to maintain structural integrity.

Preventive Measures

Using Protective Coatings

Installing protective coatings on copper pipes is a proactive measure to safeguard them against external elements and potential damage. There are various types of coatings available, each offering unique benefits for enhancing the longevity and performance of the pipes.

Epoxy Coatings: Provide a durable protective layer that resists corrosion and abrasion.

Polyethylene Sleeves: Offer insulation and protection against physical damage.

Zinc Coatings: Act as a sacrificial barrier, preventing corrosion by sacrificing themselves.

The application process for protective coatings involves thorough cleaning of the copper pipes, followed by applying the coating evenly to ensure complete coverage. Proper application is essential to maximize the protective benefits of the coating and extend the lifespan of the pipes.

Ensuring Proper Installation

Proper installation of copper pipes is critical to their long-term functionality and efficiency within air conditioning systems. Correct sizing and fitting ensure optimal water flow and prevent issues such as leaks or blockages that can compromise system performance.

Sizing Considerations: Selecting the appropriate diameter for copper pipes based on water flow requirements.

Fitting Techniques: Utilizing professional-grade fittings and tools for secure connections that minimize the risk of leaks.

Acidic Water Prevention: Avoiding acidic water exposure that can corrode the interior of copper pipes, leading to premature deterioration.

Professional installation tips from industry experts emphasize precision, cleanliness, and adherence to best practices. By following these guidelines, you can maintain the integrity of your AC system's copper pipes for years to come.

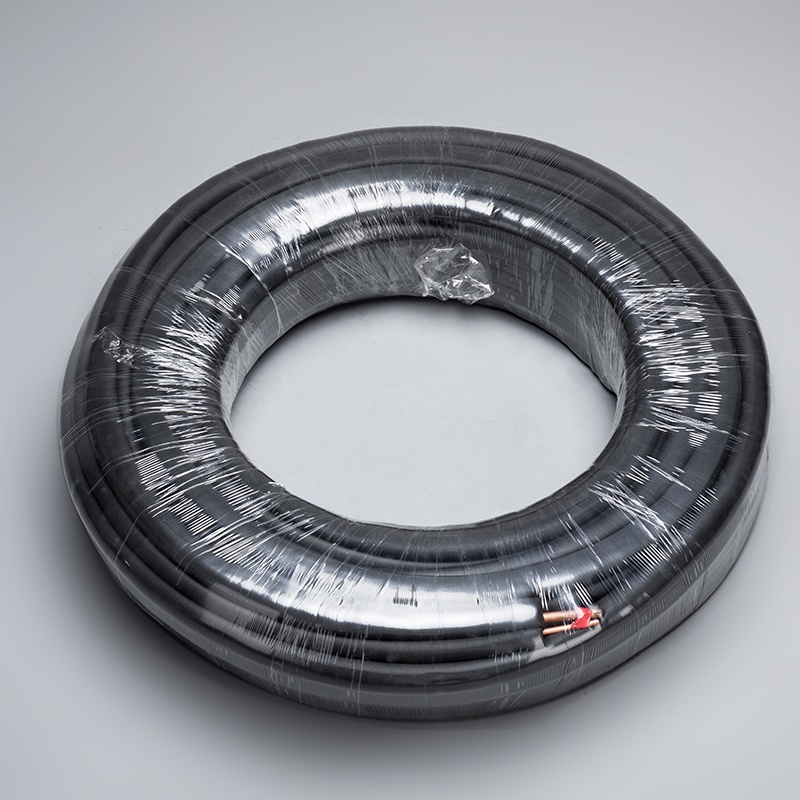

Insulating Copper Pipes

Insulating copper pipes offers multiple advantages in maintaining their efficiency and structural integrity. The benefits of insulation extend beyond temperature stabilization to include protection against condensation-related corrosion and freezing damage.

Temperature Stability: Insulation helps regulate heat transfer, ensuring consistent performance in varying environmental conditions.

Corrosion Prevention: Minimizing condensation on copper pipes reduces moisture exposure, mitigating the risk of corrosion over time.

Materials Selection: Choosing suitable insulation materials compatible with copper surfaces ensures optimal protection without causing adverse reactions.

Methods for insulating copper pipes involve wrapping them with insulating sleeves or foam tubes, securing them tightly to maintain coverage. Proper insulation enhances energy efficiency, prevents thermal losses, and prolongs the lifespan of your AC system's components.

Addressing Common Problems

When addressing common issues with copper pipes in air conditioning systems, it is crucial to be proactive in identifying and resolving potential leaks and corrosion. By implementing effective strategies for fixing leaks, dealing with corrosion, and preventing future problems, you can ensure the longevity and efficiency of your AC system.

Fixing Leaks

Temporary Fixes

In the event of a leak in your copper pipes, temporary solutions can help mitigate immediate damage. One approach is to apply a high-quality epoxy putty over the leaking area to seal it temporarily. This quick fix can provide a temporary solution until a more permanent repair can be conducted.

Permanent Solutions

For long-term leak prevention, replacing damaged sections of copper pipes with new fittings or soldered joints is essential. Properly cleaning the affected area and using professional-grade materials during the replacement process ensures a secure connection that minimizes the risk of future leaks. Investing in permanent solutions guarantees the continued efficiency of your air conditioning system.

Dealing with Corrosion

Identifying Corrosion Early

Early detection of corrosion on copper pipes is key to preventing extensive damage. Conduct regular visual inspections to identify any signs of discoloration or pitting on the surface of the pipes. Addressing corrosion early allows you to take corrective measures promptly and safeguard the integrity of your AC system.

Methods to Remove Corrosion

To effectively remove corrosion from copper pipes, start by cleaning the affected areas with a mild detergent solution and a soft brush. For stubborn corrosion, consider using a commercial metal polish specifically designed for copper surfaces. Thoroughly rinse the pipes after cleaning to eliminate any residue and restore their original shine.

Preventing Future Issues

Regular Flushing

Regularly flushing out copper pipes within your air conditioning system helps prevent mineral buildup and clogs that can impede water flow. Flushing involves running clean water through the pipes at high pressure to dislodge any debris or sediment accumulated inside. This maintenance practice promotes optimal performance and extends the lifespan of your AC system.

Avoiding Harsh Chemicals

When cleaning or maintaining copper pipes, it is essential to avoid harsh chemicals that can corrode or damage the material. Opt for gentle cleaning agents recommended for copper surfaces, such as vinegar or mild soap solutions. Harsh chemicals can accelerate corrosion and compromise the structural integrity of the pipes over time.

In conclusion, the significance of maintaining copper pipes in air conditioning systems cannot be overstated. By following the expert tips shared in this blog, homeowners can ensure the longevity and efficiency of their AC systems. Regular inspection, cleaning, and preventive measures such as using protective coatings and proper installation techniques are key to avoiding common issues like leaks and corrosion. Implementing these tips for maintaining copper pipes will not only enhance the performance of your AC system but also contribute to a more sustainable and cost-effective home environment.

See Also

Essential Tips for Keeping Copper Pipes Efficient

Best Practices for Maintaining Copper Pipe Coils

Discovering the Advantages of Copper Pipes in AC Systems