Essential Tips for Maintaining Copper Pipes in Your AC System

Tips for maintaining copper pipes in air conditioning systems

Maintaining copper pipes in air conditioning systems is essential for ensuring the longevity and efficiency of your HVAC setup. Neglecting these vital components can lead to costly repairs and potential system failures. By understanding the common issues that arise with copper pipes, you can proactively address them before they escalate. Regular maintenance not only extends the lifespan of your copper pipes but also enhances the overall performance of your AC system. Let's delve into the world of copper pipe maintenance to equip you with the knowledge needed to keep your system running smoothly.

Understanding Copper Pipes in AC Systems

Types of Copper Pipes

Soft Copper Pipes

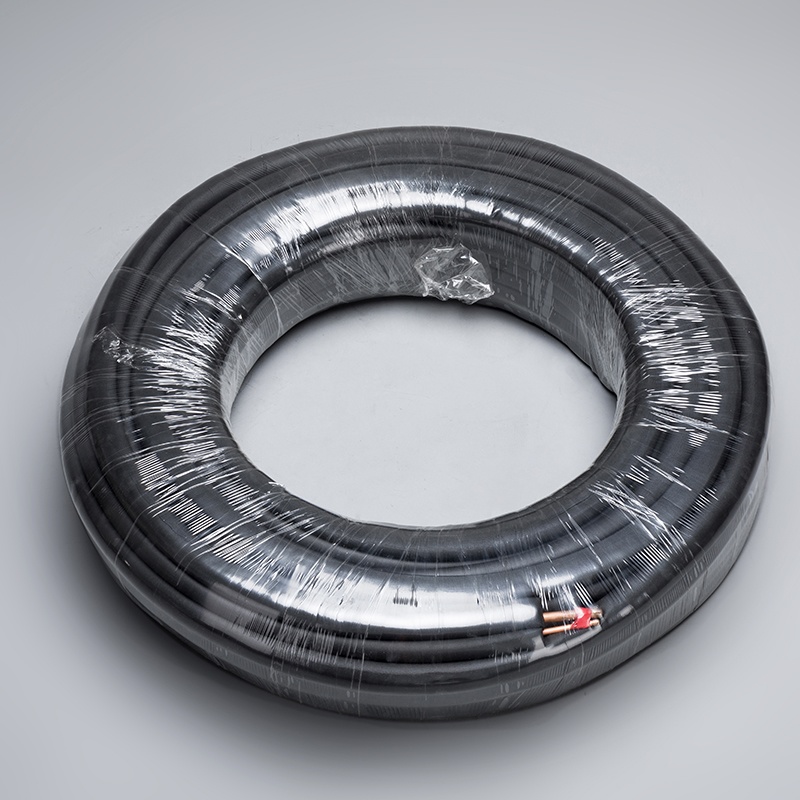

Soft copper pipes are known for their flexibility and ease of bending, making them ideal for intricate installations.

These pipes are commonly used in tight spaces where a more adaptable material is required.

Hard Copper Pipes

Hard copper pipes, on the other hand, are rigid and sturdy, suitable for long straight runs without the need for additional support.

They are often utilized in exposed areas or where the pipe needs to maintain its shape over long distances.

Role of Copper Pipes in AC Systems

Heat Exchange

Copper pipes play a crucial role in facilitating heat exchange within an air conditioning system.

The thermal conductivity of copper allows for efficient transfer of heat, aiding in the cooling process.

Refrigerant Flow

Another vital function of copper pipes is to ensure the smooth flow of refrigerant throughout the AC system.

The durability and corrosion resistance of copper make it an excellent choice for maintaining consistent refrigerant circulation.

Common Issues with Copper Pipes

Corrosion

Causes of Corrosion

Acidic Water: Water that has a pH below 6.5 can lead to corrosion in copper pipes.

High Oxygen Levels: Elevated levels of dissolved oxygen in water can also contribute to the corrosion of copper pipes.

Salt or Rust Contamination: Presence of salt or rust in the water can accelerate the corrosion process.

Corrosion occurs due to various factors such as water chemistry, flow rate, and improper installation.

Signs of Corrosion

Drop in Water Pressure: A sudden decrease in water pressure may indicate the presence of pinhole leaks caused by pipe corrosion.

Teal Stains: Teal stains in showers or tubs are visual indicators of copper pipe corrosion.

Excessive Water Pressure: Excessive pressure on small-diameter piping can be a sign of underlying corrosion issues.

Leaks

Identifying Leaks

Visual Inspection: Look for any visible signs of moisture, discoloration, or staining around the pipe joints.

Water Testing: Conduct tests to check for any unexpected drops in water pressure which could signify leaks.

Pinholes can form due to high chloramine levels, leading to accelerated pipe failure.

Preventing Leaks

Regular Maintenance: Perform routine inspections and maintenance to catch potential issues early.

Proper Insulation: Insulate copper pipes to prevent temperature fluctuations that may contribute to leaks.

Essential Maintenance Tips

Regular Inspections

To ensure the longevity of your air conditioning system, maintaining copper pipes in air conditioning systems is crucial. Here are some essential maintenance tips to help you keep your system running smoothly.

Visual Inspections

Begin by visually inspecting all exposed copper pipes for any signs of corrosion or leaks.

Look for discoloration, green oxidation, or moisture around the pipe joints as potential indicators of issues.

Check for any unusual bends or kinks in the pipes that could affect their performance.

Professional Inspections

Schedule regular inspections with a professional HVAC technician to assess the overall condition of your copper pipes.

Professionals can conduct more in-depth tests and evaluations to identify any hidden problems early on.

Seek expert advice on preventive measures and maintenance routines tailored to your specific AC system.

Cleaning Copper Pipes

Proper cleaning of copper pipes is essential to maintain their efficiency and prevent potential issues down the line.

Tools Needed

Gather white vinegar, baking soda, a soft-bristled brush, and clean cloths for the cleaning process.

Ensure you have protective gloves and goggles to safeguard yourself from any cleaning solutions used.

Have a spray bottle filled with vinegar ready for application on affected areas.

Step-by-Step Cleaning Process

Create a paste using baking soda and water, then apply it to areas with green oxidation or patina buildup.

Let the paste sit for a few minutes before gently scrubbing it off with a soft-bristled brush.

Spray white vinegar on stubborn spots and wipe them clean with a cloth to reveal shiny copper surfaces.

Preventing Corrosion

Protecting your copper pipes from corrosion is vital for maintaining their structural integrity and performance over time.

Protective Coatings

Apply a thin coat of gloss spray-on clear lacquer to create a protective barrier against environmental elements.

Regularly check the condition of the coating and reapply as needed to ensure continuous protection.

Consider using commercial metal polish for additional shine and protection against corrosion.

Environmental Controls

Monitor humidity levels in areas where copper pipes are installed to prevent condensation buildup that can lead to corrosion.

Implement temperature controls to stabilize the operating conditions around copper pipes and reduce thermal stress.

Keep surrounding areas clean and free from debris that could potentially damage or corrode the copper piping material.

Insulating Copper Pipes

Benefits of Insulation

Enhances energy efficiency by reducing heat loss during the cooling process, optimizing the overall performance of the AC system.

Minimizes the risk of condensation buildup on copper pipes, preventing potential corrosion and water damage.

Stabilizes the temperature of the pipes, ensuring consistent operation and extending their lifespan.

Protects surrounding structures from temperature fluctuations, maintaining a comfortable indoor environment.

How to Insulate

Begin by selecting appropriate insulation materials such as foam sleeves or fiberglass wraps designed for copper pipes.

Measure the length of the pipes accurately to cut the insulation to the correct size for a snug fit.

Wrap the insulation around the copper pipes securely, ensuring there are no gaps or exposed areas left uncovered.

Use adhesive or tape to seal any seams or joints in the insulation to maximize its effectiveness.

Pay special attention to areas where pipes are exposed to external elements or fluctuating temperatures for comprehensive coverage.

Professional Maintenance Services

When to Call a Professional

Signs You Need Professional Help

Notice any sudden increase in energy bills without a clear cause.

Experience inconsistent cooling performance or uneven temperature distribution in different areas of your space.

Detect unusual noises coming from your AC system during operation, indicating potential issues.

Observe water leaks around the base of your air conditioner or near the copper pipes.

Smell strange odors like musty or burning scents when your AC is running, signaling possible internal problems.

Choosing a Reliable Service

Research local HVAC companies with positive reviews and a good reputation for quality service.

Inquire about the technicians' certifications and experience in handling copper pipe maintenance for AC systems.

Request quotes from multiple providers to compare pricing and services offered before making a decision.

Verify that the chosen service provider offers warranties on their workmanship and parts for added peace of mind.

Seek recommendations from friends or family members who have previously used professional maintenance services for their air conditioning systems.

Maintaining copper pipes in your AC system is a crucial task to ensure optimal performance and longevity. By following the key maintenance tips provided, you can prevent costly repairs and system failures. Remember to conduct regular inspections, clean the pipes effectively, and protect them from corrosion. Whether you choose DIY maintenance or seek professional help, taking action now will benefit your AC system in the long run. Start your maintenance routine today to enjoy a well-functioning air conditioning setup for years to come.

See Also

Essential Tips for Efficient Copper Pipe Maintenance

Best Practices for Maintaining Copper Pipe Coils

Discovering the Advantages of Copper Pipes in AC Systems