Essential Tips for Proper Flaring of Copper Pipes in Air Conditioners

Write a 'Tips' blog post on 'Tips for Proper Flaring of Copper Pipes in Air Conditioners'

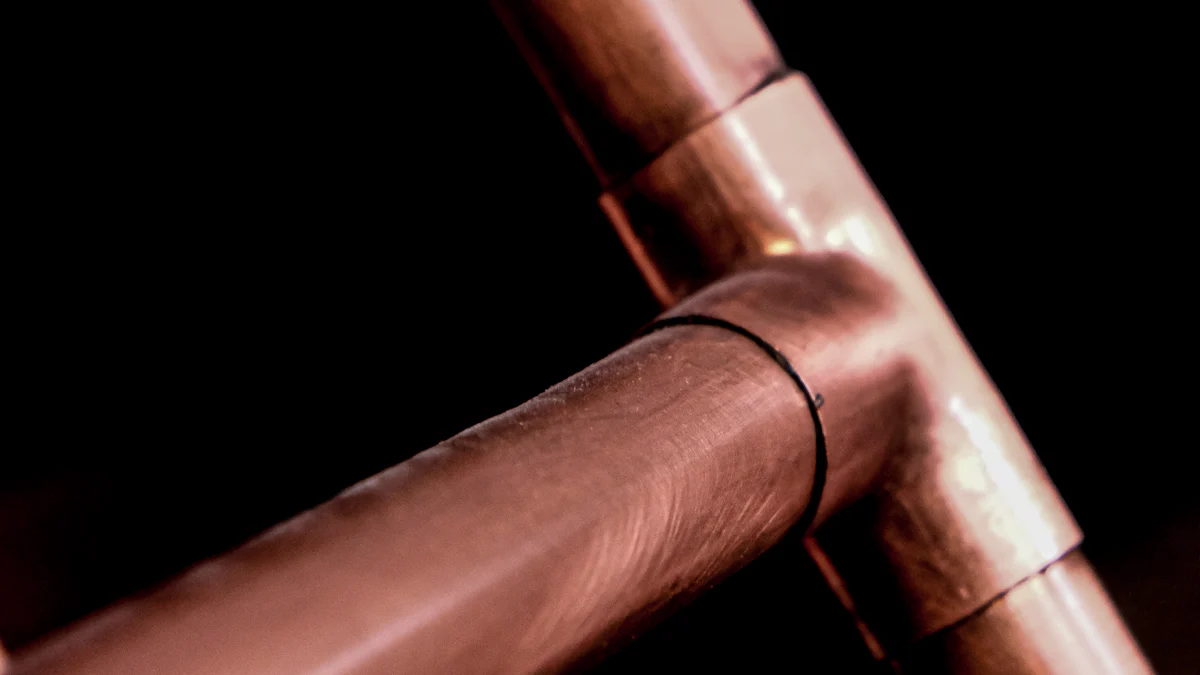

Proper flaring in air conditioners is crucial for ensuring a secure connection and preventing leaks. Understanding the key tips and techniques can significantly enhance system efficiency and avoid damage to pipes. Flare fittings, essential for transporting refrigerants and high-pressure fluids, rely on quality flaring tools to form tight fits. These tools, with their ability to create robust mechanical joints, play a vital role in HVAC systems. By following expert advice on pipe preparation and tool selection, professionals and enthusiasts alike can achieve optimal results.

Importance of Proper Flaring

When flaring copper pipes in air conditioners, the primary focus lies on ensuring a secure connection and preventing leaks. This process is not merely about joining pipes; it's about creating a robust, leak-free junction that can withstand the pressures of HVAC systems. The significance of proper flaring cannot be overstated, especially when considering the long-term integrity of the entire system.

Ensuring a Secure Connection

To prevent leaks effectively, professionals emphasize the importance of using high-quality flaring tools. These tools play a crucial role in enlarging pipe ends to create flares that provide a tight fit. By utilizing these tools correctly, individuals can ensure that the connection points are sealed efficiently, reducing the risk of refrigerant leaks and system inefficiencies.

Avoiding Damage to Pipes

Maintaining pipe integrity is essential for the longevity and performance of air conditioning systems. Improper flaring techniques can lead to structural damage within the pipes, compromising their functionality over time. By extending the pipe lifespan through proper flaring practices, HVAC specialists can guarantee optimal system operation and minimize maintenance requirements.

The use of flare fittings in HVAC applications has been extensively studied for their role in creating secure connections and preventing leaks. Flare tools are indispensable for professionals and amateurs alike when it comes to achieving leak-free junctions in air conditioning systems.

Step-by-Step Flaring Tips

Preparing the Pipe

To start the flaring process, the first step involves reaming the end of the copper pipe. This crucial step ensures a smooth and clean surface for creating a proper flare. By using a reaming tool, professionals can remove any imperfections or burrs that may affect the quality of the flare.

Following reaming, the next essential task is deburring the pipe. This process involves removing any sharp edges or irregularities left on the pipe after reaming. A deburred pipe guarantees a precise and secure fit during the flaring process, reducing the risk of leaks and ensuring optimal system performance.

Using the Flaring Tool

Selecting the appropriate flaring tool is paramount to achieving a successful flare. Professionals must choose a tool that matches the diameter of the copper pipe to ensure an accurate and secure connection. By using high-quality tools, individuals can create consistent flares that meet industry standards.

Once the tool is selected, it is crucial to maintain stability throughout the flaring process. Keeping the flare steady while operating the tool prevents any distortions or deformations in the flare shape. This practice guarantees a uniform and reliable connection between pipes and fittings.

Finalizing the Flare

After forming the flare, it is essential to verify its shape for accuracy and precision. Inspecting the flare ensures that it meets specifications and will provide a leak-free connection in air conditioning systems. Any deviations from the correct shape should be addressed promptly to avoid future issues.

To complete this step, professionals must ensure a tight fit between components. A secure connection minimizes potential leaks and enhances system efficiency by maintaining consistent pressure levels within HVAC systems. Properly fitting components contribute to overall system reliability and longevity.

Common Mistakes to Avoid

When flaring copper pipes in air conditioners, professionals must be vigilant to avoid common errors that could compromise the integrity of the system. Overflaring the pipe can lead to unnecessary stress on the material, potentially causing leaks and reducing overall efficiency. It is crucial to exercise caution and precision during this process to ensure a secure connection without damaging the pipe.

Skipping the annealing process is another critical mistake that individuals should avoid when working with copper tubing. Annealing involves heating the tube to make it more malleable before flaring, especially for hard temper tubes. By skipping this step, technicians risk creating weak connections that may fail under pressure, leading to leaks and system malfunctions.

To prevent these errors, professionals should adhere strictly to industry best practices and guidelines for proper flaring techniques. By recognizing and avoiding these common mistakes, individuals can enhance the longevity and performance of air conditioning systems while minimizing the need for costly repairs.

Recap of Essential Tips:

Implementing proper flaring techniques is essential for creating secure connections and preventing leaks in air conditioning systems.

By following step-by-step procedures, professionals can ensure the longevity and efficiency of copper pipes.

Emphasis on the Importance of Proper Technique:

HVAC professionals rely on fundamental tools like multimeters, refrigerant leak detectors, and tube cutters to maintain optimal system performance.

Maintaining these tools ensures the ability to identify and resolve issues effectively, guaranteeing reliable HVAC operation.

Suggestions for Future Maintenance and Care:

Swastik Electrotech Pvt Ltd offers descaling services to remove mineral buildup and restore HVAC efficiency.

Regular maintenance, including descaling, is crucial for preserving system performance and ensuring comfort throughout the year.

See Also

Best Flaring Equipment for Copper Piping Projects

Selecting the Top Flaring Tool for 1/2 Copper Pipe

Importance of Copper Pipes for Effective Air Conditioning