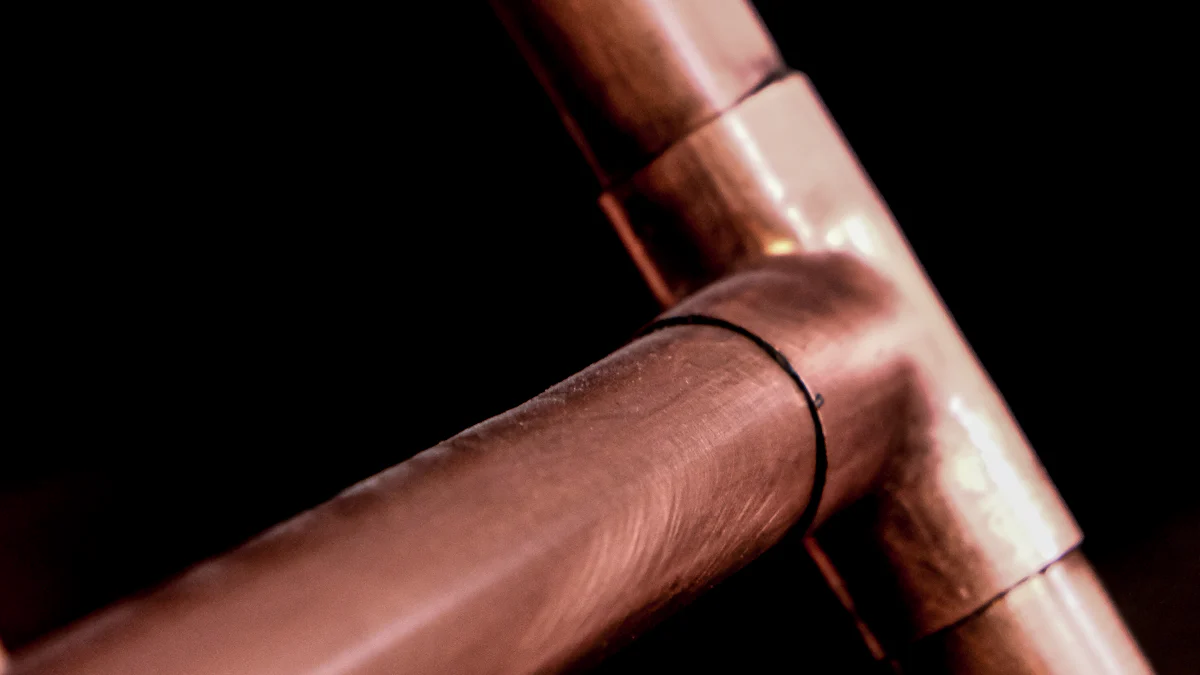

Essential Tools for Reaming Copper Pipes: A Guide

Guide: Tools needed for reaming copper pipes

Reaming copper pipes is a crucial step in ensuring precise and uniform holes for various applications. By using reamers, professionals can enlarge holes with high accuracy, creating a smooth surface finish that is essential in industries like automotive and aerospace. Reamers remove small amounts of material from the inside walls of the hole, guaranteeing a perfect diameter. These tools are versatile, compatible with all metals, from soft brass to hard stainless steel. Understanding the importance of reaming tools and their role in achieving precision is key to successful pipe work.

Tools Overview

Purpose of Reaming

Reamers, the highest-precision tools in use, ensure holes are within a tolerance of 0.0002 inches. The grinding process with a reamer cutting tool expands the hole by no more than 10%, creating precise fits for various purposes. The 'hole basis' tolerance system allows shaft sizes to be adjusted, from 'free running fits' to 'force fit', meeting assembly needs with tight precision.

Reducing Turbulence

By using reamers, turbulence inside copper pipes is minimized, ensuring a smooth flow of liquids through the lines. This reduction in turbulence prevents disruptions in fluid movement and optimizes the efficiency of the piping system.

Ensuring Smooth Connections

Reaming copper pipes guarantees that connections are secure and leak-free. The precise enlargement of holes with reamers ensures that fittings and joints fit perfectly, eliminating any gaps or irregularities that could compromise the integrity of the pipe network.

Types of Tools

Reaming tools come in two main categories: manual tools and power tools. Each type offers unique advantages based on the specific requirements of the project at hand.

Manual Tools

Manual reaming tools provide control and precision when working on copper pipes. They are ideal for projects that require a hands-on approach and meticulous attention to detail. Common manual tools include half-round or round files, which allow for gradual material removal while maintaining accuracy.

Power Tools

Power reaming tools offer efficiency and speed in larger-scale projects or when dealing with harder materials. These tools are powered by electricity or batteries, providing consistent performance and reducing manual effort during the reaming process.

Specific Tools

Half-Round and Round Files

Hand reamers, such as half-round and round files, are essential tools for reaming copper pipes. These precision-ground cutting tools are designed to expand pre-drilled holes to an exact diameter by hand. The straight or slightly twisted flutes of the files ensure accurate sizing, while the slight bevel at the tip allows for a precise start at the desired angle. Half-round and round files are versatile tools that can correct imperfectly rounded or irregular holes in copper pipes with ease.

Usage

Begin by inserting the file into the hole you want to ream.

Rotate the file gently in a clockwise direction to remove any burrs or imperfections.

Continue this process until you achieve the desired smoothness and diameter.

Benefits

Half-round and round files provide manual control over the reaming process, ensuring precision.

These tools are ideal for small-scale projects that require attention to detail.

They allow for gradual material removal, resulting in accurately sized and smooth holes in copper pipes.

Pocket Knife

A pocket knife is a versatile tool that can also be used for deburring copper pipes after cutting. While not specifically designed for reaming, a sharp pocket knife can effectively remove burrs from the inside of tubing, ensuring a clean finish before connecting pipes. Pocket knives are handy additions to any toolkit for quick deburring tasks on-site.

Usage

Carefully run the blade of the pocket knife along the inside edges of the cut pipe.

Apply gentle pressure to shave off any burrs or rough edges effectively.

Benefits

Pocket knives offer portability and convenience for deburring tasks in tight spaces.

They provide a quick solution for minor burr removal on copper pipes without requiring additional specialized tools.

Deburring Tools

Types of Deburring Tools

Deburring tools come in various types, including hand reamers and specialized deburring pens like Milwaukee 48224255 Reaming & Deburring Pen. These tools are designed to remove burrs efficiently from copper pipes, ensuring smooth connections and optimal flow through the lines.

Usage

Select an appropriate deburring tool based on the pipe diameter.

Run the tool along the inner edges of the pipe to remove any burrs or sharp edges effectively.

Benefits

Deburring tools help maintain proper flow within copper pipes by eliminating obstructions.

They ensure secure connections between pipes, reducing leaks and enhancing system efficiency.

Pen Reamers

Pen reamers are essential tools for professionals working with copper pipes. These precision tools are designed to peel off decent-sized chunks of material, making it easier to keep up with and remove burrs effectively. By using pen reamers, workers can ensure that the inner walls of copper pipes are smooth and free from obstructions, allowing for optimal fluid flow through the lines.

Usage

Start by selecting the appropriate pen reamer based on the diameter of the pipe.

Insert the pen reamer into the pipe and rotate it gently to remove any burrs or imperfections.

Continue this process until the inner surface of the pipe is clean and smooth.

Benefits

Pen reamers offer precision in removing burrs from copper pipes, ensuring a consistent inner diameter.

These tools make deburring tasks efficient and manageable, saving time during pipe preparation.

Using pen reamers results in clean and smooth pipe surfaces, promoting better connections and reducing turbulence in fluid flow.

Rerounding Tools

Professionals often utilize rerounding tools when working with Type K copper tubing to ensure a secure fit for compression fittings. Rerounding tools enable workers to quickly reshape tubing that may have deformed during handling or installation, guaranteeing a proper seal for connections.

Usage

Choose an appropriate rerounding tool based on the size of the copper tubing.

Gently insert the tool into the tubing and apply slight pressure to reshape any irregularities.

Verify that the tubing has been properly rerounded before proceeding with fitting connections.

Benefits

Rerounding tools help maintain the integrity of Type K copper tubing by correcting deformations without compromising its structural strength.

Using these tools ensures a snug fit for compression fittings, reducing the risk of leaks or connection failures.

Rerounding tools promote efficiency in plumbing projects by quickly resolving tubing deformities without requiring extensive manual labor.

Best Practices

Tool Maintenance

Regularly inspect Reamers for signs of wear, such as chipping or dullness.

Keep Reamers clean and free from debris to maintain their precision and effectiveness.

Store Reamers in a dry and secure place to prevent damage and ensure longevity.

Use appropriate lubrication when operating Reamers to reduce friction and extend their lifespan.

Sharpen Reamers when necessary to maintain optimal cutting performance.

Safety Tips

Always wear protective gear, including gloves and safety goggles, when using Reaming tools to prevent injuries.

Ensure proper ventilation in the workspace to avoid inhaling metal particles or dust during the reaming process.

Secure workpieces firmly in place before reaming to prevent slippage or accidents.

Follow manufacturer guidelines and recommendations for operating Reaming tools safely and effectively.

Keep hands away from cutting edges while using Reaming tools to avoid cuts or lacerations.

By following these best practices for tool maintenance and implementing essential safety tips, professionals can enhance the efficiency and safety of their copper pipe reaming projects.

Recapping the essential tools for reaming copper pipes is crucial to ensure precise and smooth connections. Proper reaming with tools like half-round and round files, pocket knives, and deburring tools guarantees secure fittings and reduces turbulence in fluid flow. Understanding the significance of maintaining these tools regularly and following basic safety measures is paramount for preventing severe injuries during pipe work. By prioritizing tool maintenance and safety, professionals can enhance project efficiency and promote a safe working environment. Remember, precision in reaming leads to reliable connections and optimal performance in various applications.

See Also

Becoming an Expert in Copper Pipe Fittings: The Complete Manual

The Indispensable Handbook for 3-Inch Copper Pipe Fittings

Mastering Copper Pipe Fittings: The Ultimate Handyman's Manual