The Evolution of Quality Control in Copper Pipe Coils

The significance of maintaining quality control in copper piping cannot be overstated. Ensuring the reliability and safety of water services is paramount, especially considering that low levels of copper are naturally present in all water sources. When transitioning from lead pipes to copper plumbing, experts initially believed that copper pipes would last significantly longer, up to 20 to 25 years. However, two crucial factors were overlooked: the quality of the copper pipes and the quality of the water they carry. This blog will delve into the evolution of quality control techniques in modern 1/4 3/8 twin copper pipe coils manufacturing, shedding light on advanced inspection methods and industry standards.

Historical Overview

Early Uses of Copper Pipes

Ancient Egyptian Plumbing

Copper pipes have a rich history dating back to ancient civilizations. In Egypt, copper piping was utilized in plumbing systems, showcasing the durability and reliability of this metal. The intricate network of copper pipes found in archaeological excavations highlights the advanced plumbing practices of that era.

Post-WWII Developments

Following World War II, there was a significant shift in the materials used for plumbing systems. Copper emerged as the material of choice due to its superior quality and longevity. This transition marked a pivotal moment in the evolution of plumbing, emphasizing the importance of quality control measures to ensure the efficiency and safety of water services.

Initial Quality Control Measures

Basic Inspection Techniques

In the early stages of copper pipe production, basic inspection techniques were employed to assess the quality and integrity of the pipes. Visual inspections and manual testing were conducted to identify any defects or imperfections in the copper material. These fundamental measures laid the foundation for more advanced quality control practices in the future.

Transition from Lead to Copper

The transition from lead pipes to copper was driven by a growing awareness of the health risks associated with lead contamination. Copper's superior properties, including its resistance to corrosion and microbial growth, made it an ideal alternative for water distribution systems. This shift underscored the need for stringent quality control measures to guarantee that copper pipes met industry standards and regulations.

By embracing these initial quality control measures and transitioning from lead to copper piping, early plumbers paved the way for advancements in modern plumbing systems. The evolution of quality control techniques continues to play a crucial role in ensuring the reliability and safety of copper pipe coils in contemporary manufacturing processes.

Modern Quality Control Techniques

Advanced Inspection Methods

Copper, as the best nonprecious conductor of heat and electricity, plays a crucial role in ensuring the efficiency of electricity generation and delivery. Using inferior conductors can result in wasted energy, higher utility bills, and increased greenhouse-gas emissions. To maintain quality standards, advanced inspection methods are employed to assess the integrity of copper pipes without causing damage.

Non-Destructive Testing

Non-destructive testing techniques are essential for evaluating the quality of copper pipe coils. These methods allow inspectors to identify any defects or imperfections in the material without altering its structure. By utilizing innovative technologies such as ultrasound testing and eddy current testing, manufacturers can ensure that only high-quality copper pipes enter the market.

Automated Quality Control Systems

Automated quality control systems have revolutionized the manufacturing process of copper pipe coils. These systems use cutting-edge technology to monitor every stage of production, from raw material inspection to final product testing. By automating quality control processes, manufacturers can enhance efficiency, reduce human error, and guarantee consistent product quality.

Standards and Certifications

Maintaining industry standards and certifications is paramount in the production of copper pipe coils. Adhering to established guidelines ensures that all products meet regulatory requirements and deliver optimal performance.

Industry Standards

Industry standards dictate the specifications that copper pipe coils must meet to be considered safe and reliable for various applications. These standards cover aspects such as material composition, dimensions, and performance characteristics. By following industry standards set by organizations like ASTM International and ANSI, manufacturers can produce high-quality copper pipe coils that meet customer expectations.

Certification Processes

Certification processes involve rigorous testing and evaluation procedures to verify that copper pipe coils comply with industry standards. Third-party certification bodies assess product quality through independent testing and auditing. Achieving certifications such as NSF/ANSI 61 demonstrates a manufacturer's commitment to producing safe and environmentally friendly products.

Investigate the evolution of quality control techniques in modern 1/4 3/8 twin copper pipe coils man

Investigating the evolution of quality control techniques in modern 1/4 3/8 twin copper pipe coils manufacturing reveals a commitment to enhancing product reliability and safety through specialized approaches.

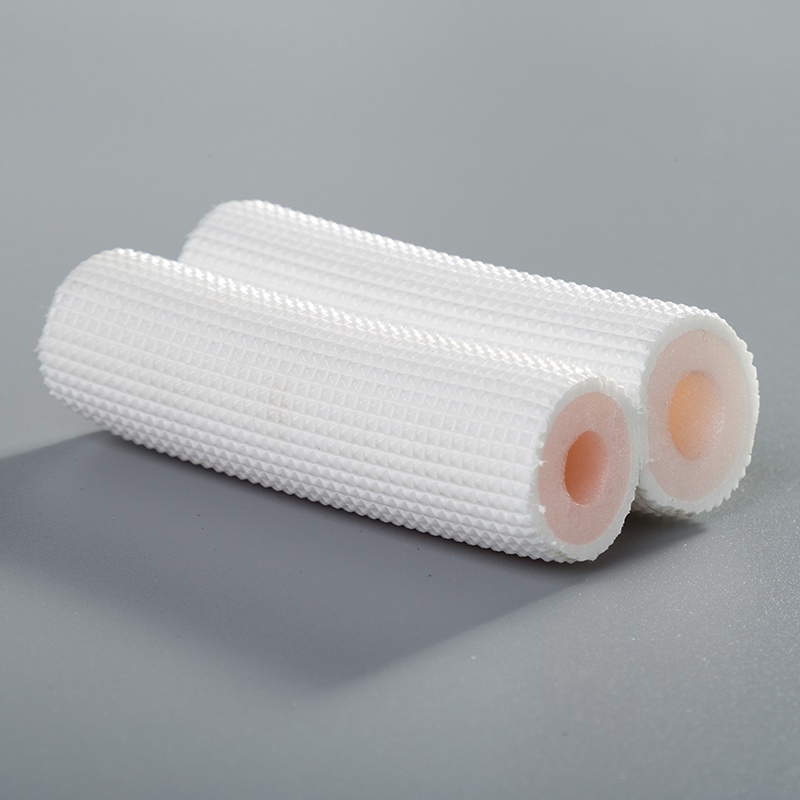

Specific Techniques for Twin Copper Pipe Coils

Specific techniques tailored for twin copper pipe coils focus on ensuring uniformity in dimensions, wall thickness, and surface finish. Precision manufacturing processes coupled with stringent quality control measures guarantee that twin copper pipe coils meet exact specifications for compatibility with diverse plumbing systems.

Case Studies and Examples

Examining case studies and examples from leading manufacturers showcases innovative practices adopted in modern 1/4 3/8 twin copper pipe coil production. Real-world scenarios highlight how advanced inspection methods, automation technologies, and adherence to industry standards have elevated the quality control process in manufacturing facilities.

Future Trends

Emerging Technologies

The future of copper pipe technology looks promising, with advancements on the horizon. Various methods like rolling, extrusion, and casting are currently used in production operations. Further technological improvements are anticipated, aiming to reduce production costs while enhancing product quality. Nikita Shagov predicts that these advancements will revolutionize the industry, making copper piping even more efficient and reliable.

Incorporating AI and Machine Learning into quality control processes is one such advancement. These technologies enable real-time monitoring of production lines, identifying potential defects or irregularities before they impact the final product. By leveraging AI algorithms and machine learning models, manufacturers can streamline their operations and ensure consistent quality across all 1/4 3/8 twin copper pipe coils.

Another trend on the horizon is the implementation of Predictive Maintenance strategies. By analyzing data from sensors embedded in manufacturing equipment, predictive maintenance systems can forecast when maintenance is required before breakdowns occur. This proactive approach minimizes downtime, reduces repair costs, and prolongs the lifespan of machinery used in copper pipe coil production.

Sustainability and Environmental Considerations

The increasing demand for environmentally friendly materials has put a spotlight on copper pipes as a sustainable choice. Unlike some materials that harm the environment during production, copper pipes align with sustainable development goals due to their eco-friendly manufacturing process. The minimal environmental impact of producing copper pipes makes them an attractive option for environmentally conscious consumers.

Copper's versatility extends beyond plumbing; it is a vital component in various everyday items and industries. From pots and pans to water pipes in homes, copper's role in electronics, appliances, construction, and even cars cannot be overstated. Its conductivity properties make it indispensable in modern technology while its durability ensures longevity in various applications.

Regulatory changes are also shaping the future landscape of copper pipe manufacturing. As environmental regulations become more stringent worldwide, manufacturers must adapt their practices to meet compliance standards. Embracing eco-friendly materials and sustainable production methods will not only ensure regulatory adherence but also position companies as leaders in environmentally responsible manufacturing practices.

Ensuring the quality of copper piping is essential for long-lasting plumbing systems. Understanding water chemistry and preventing issues like buildup and leaks are crucial factors in maintaining reliable water services. Copper pipes, with their sustainable properties and aesthetic appeal, continue to be in demand across various industries. Recognizing the presence of lead and copper in plumbing materials is vital to safeguard against potential health risks.

See Also

Exploring the Precision of Copper Pipe Coil Inspection

Revealing the Hidden Techniques of Copper Pipe Coil Production

Innovative Approaches to Ensuring Copper Pipe Coil Quality

Discovering the Progression of Copper Tubing in HVAC

Anticipating the Advancements in Copper Pipe Coil Technology