How to Extend the Lifespan of Copper Pipe Coils

To Discover effective strategies for prolonging the lifespan of 1/4 3/8 twin copper pipe coils, one must grasp the significance of maintaining these vital components. With a typical lifespan ranging from 50 to 70 years, copper pipe coils play a crucial role in plumbing systems. However, various factors can diminish their longevity. Frequent water pressure fluctuations, extreme temperatures, and subpar installation practices can all contribute to premature wear and tear. This blog delves into preventive maintenance techniques, best installation practices, and troubleshooting tips to empower homeowners in safeguarding their copper pipe coils.

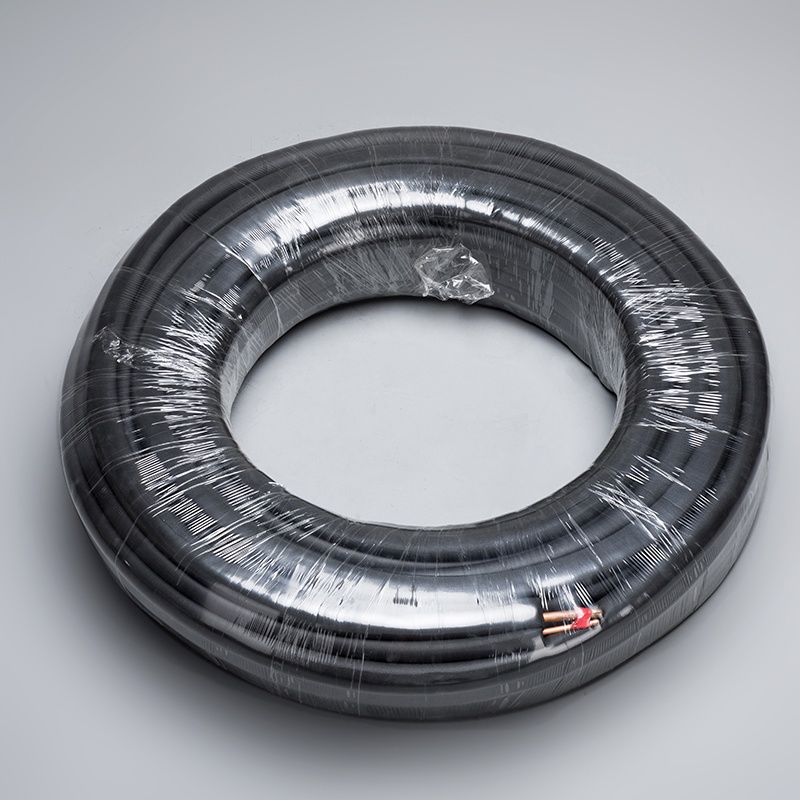

Understanding Copper Pipe Coils

Copper Pipe Coils, known for their versatility, are utilized in various industries worldwide for different applications such as induction energy exchange and heating/cooling. These coils, made of durable copper, offer several advantages over other materials. Let's delve into the common uses and benefits of Copper Pipe Coils.

Common Uses

RF induction for endometriosis brazing procure device in the medical industry

RF heat transfer or induction unit device-part for auto-parts assembly-line industry

RF matching, cleaning, and processing on a semiconductor resonator

Liquid/air transfer coil for cooling or heating liquid/air in manufacturing machining devices

Benefits of Copper

Copper tube coils are more resistant to damage compared to aluminum coils.

They are easier to clean and maintain.

The durability of copper ensures longevity in various applications.

Preventive Maintenance

To ensure the longevity of 1/4 3/8 twin copper pipe coils, homeowners must prioritize Discover effective strategies for prolonging the lifespan of 1/4 3/8 twin copper pipe coils through diligent preventive maintenance. Regular inspections play a pivotal role in identifying early signs of wear and addressing potential issues promptly. Cleaning and flushing procedures are essential to maintain optimal performance, while protective measures like insulation and anti-corrosion coatings safeguard the integrity of the copper pipe coils.

Regular Inspections

Inspecting copper pipe coils regularly is paramount in maintaining their efficiency and durability. By identifying early signs of wear, homeowners can intervene before minor issues escalate into major problems. Utilizing tools and techniques for inspection enhances the thoroughness of assessments, ensuring that no potential concerns go unnoticed.

Cleaning and Flushing

Regular cleaning using recommended agents is crucial for preventing buildup that can compromise the functionality of copper pipe coils. Proper flushing techniques help remove debris and sediment that may accumulate over time, preserving the smooth flow of liquids through the coils. This maintenance routine contributes significantly to extending the lifespan of the plumbing system.

Protective Measures

Implementing protective measures such as insulation shields copper pipe coils from external stressors that could lead to premature deterioration. Additionally, applying anti-corrosion coatings acts as a barrier against chemical reactions that may compromise the structural integrity of the pipes. These proactive steps fortify the longevity of 1/4 3/8 twin copper pipe coils, ensuring sustained performance over time.

Best Practices for Installation

When it comes to Discover effective strategies for prolonging the lifespan of 1/4 3/8 twin copper pipe coils, proper installation practices are paramount. Homeowners can ensure the longevity of their plumbing system by adhering to best practices during the installation process.

Proper Handling

To begin, avoiding physical damage is crucial when working with copper pipe coils. Mishandling can lead to dents or bends that compromise the integrity of the pipes. By exercising caution and using appropriate tools, homeowners can prevent unnecessary damage and maintain the quality of the coils.

Correct bending techniques are equally essential for preserving the structural stability of copper pipe coils. Improper bending can weaken the material and result in leaks or cracks over time. Following manufacturer guidelines and utilizing bending tools effectively are key steps in ensuring a secure and durable installation.

Correct Installation Procedures

Ensuring secure connections is a fundamental aspect of installing copper pipe coils effectively. Properly sealed connections prevent leaks and maintain consistent water flow throughout the plumbing system. Homeowners should double-check fittings and joints to guarantee a tight seal that withstands pressure variations.

Avoiding common mistakes during installation is also critical for maximizing the lifespan of copper pipe coils. Errors such as overtightening fittings or using incompatible materials can lead to premature wear and potential failures. By following industry standards and seeking professional guidance when needed, homeowners can avoid costly mistakes and enjoy a reliable plumbing system.

Troubleshooting and Repairs

Common Issues and Solutions

Leaks

Inspect the entire length of the copper pipe coils for any signs of moisture or water stains.

Utilize a pressure gauge to identify fluctuations that may indicate a leak in the system.

Apply a high-quality epoxy resin specifically designed for plumbing repairs to seal any leaks effectively.

Corrosion

Implement routine water quality tests to monitor pH levels and detect any imbalances that could accelerate corrosion.

Consider installing a water softener if your area has hard water, as this can reduce the risk of corrosion in copper pipes.

Apply a protective coating to the affected areas using anti-corrosion paint to prevent further degradation.

When to Replace vs. Repair

Cost-Benefit Analysis

Calculate the total repair costs, including materials and labor, versus the expense of replacing the entire section of copper pipe coils.

Evaluate the remaining lifespan of the coils after repairs to determine if replacement would be more cost-effective in the long run.

Long-term Considerations

Consult with a professional plumber to assess the overall condition of your copper pipe coils and receive expert advice on whether repair or replacement is the optimal choice.

Factor in future maintenance expenses and potential risks associated with continued use of deteriorating coils when making your decision.

Prioritize long-term durability and efficiency to ensure a reliable plumbing system for years to come.

Benefits of using custom copper coils:

Lightweight: Custom copper coils are easy to handle and install.

Strong: They provide durability and structural integrity.

High thermal conductivity: Efficient heat transfer for optimal performance.

Long-lasting: Ensures extended lifespan with minimal maintenance required.

Anti-microbial: Resistant to microbial growth, maintaining cleanliness.

Corrosion resistant: Protection against deterioration over time.

Easily formed into a shape: Versatile design options for various applications.

Reusable and recyclable: Sustainable choice for eco-friendly solutions.

Implement these benefits by prioritizing regular maintenance and proper installation techniques. Follow best practices diligently to ensure the longevity of your copper pipe coils. Start today for a reliable plumbing system tomorrow!

See Also

Maximize Copper Pipe Coil Longevity with This Comprehensive Guide

Best Practices for Extending Lifespan of 1/4 3/8 Copper Pipe Coils

Essential Maintenance Guidelines for Copper Pipe Coils

Uncover the Lifespan of Copper Pipes Buried Underground

Effortless DIY Guide to Professional Copper Pipe Coil Installation