Unveiling the Green Impact of Twin Copper Pipe Coils

The shift towards sustainable energy solutions has propelled the HVAC industry to prioritize environmentally friendly practices. Exploring the environmental impact of using 1/4 3/8 twin copper pipe coils with white PE insulation reveals a significant step towards energy efficiency and reduced carbon footprint. These coils, designed for air conditioning units, play a crucial role in enhancing sustainability within HVAC systems. This blog aims to delve into the benefits and implications of incorporating these innovative components, highlighting their pivotal role in advancing eco-conscious practices.

Environmental Impact Overview

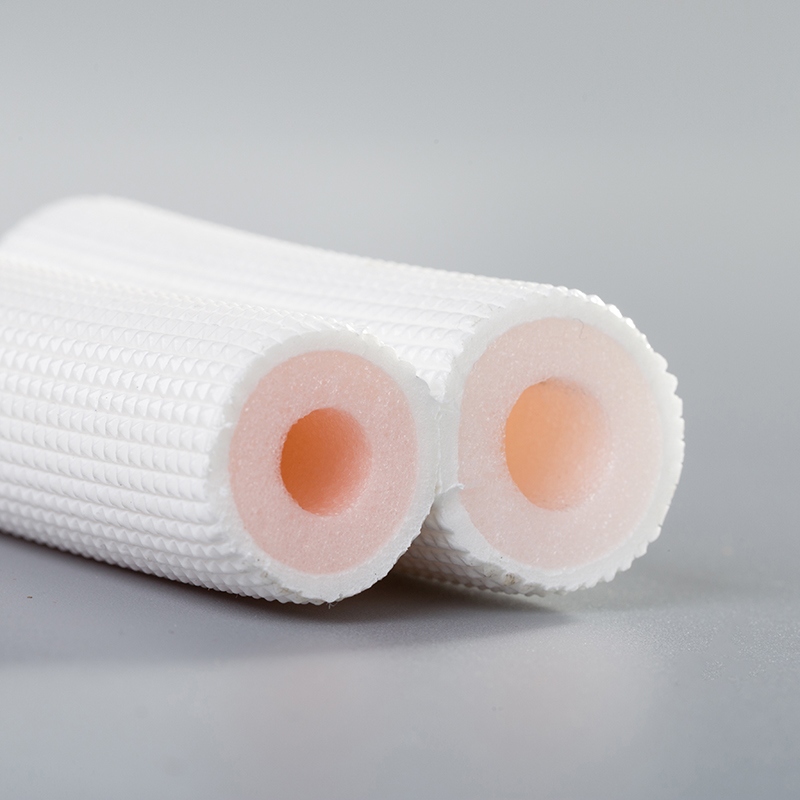

Exploring the environmental impact of using 1/4 3/8 twin copper pipe coils with white PE insulation

When considering the energy efficiency benefits of utilizing 1/4 3/8 twin copper pipe coils with white PE insulation, it becomes evident that these components play a crucial role in enhancing the overall sustainability of HVAC systems. By efficiently transferring heat and maintaining optimal performance levels, these coils contribute significantly to reducing energy consumption and operational costs.

In comparison with other materials, the environmental advantages of copper stand out prominently. Copper is known for its exceptional conductivity and durability, making it a preferred choice for HVAC applications. The use of copper pipe coils ensures longevity and reliability, thereby minimizing the need for frequent replacements and reducing waste generation in the long run.

Moreover, the impact of PE insulation on the environmental footprint of HVAC systems cannot be overlooked. White PE insulation not only enhances the thermal efficiency of copper pipes but also adds a layer of protection against external elements, prolonging the lifespan of the entire system. This combination results in a sustainable solution that aligns with modern eco-conscious practices.

Real-world applications and case studies further emphasize the significance of incorporating twin copper pipe coils with white PE insulation in both residential and commercial HVAC systems. For instance, in residential settings, these coils enable homeowners to achieve optimal indoor comfort while minimizing energy consumption. On the other hand, commercial establishments benefit from improved operational efficiency and reduced maintenance costs by leveraging these innovative components.

Material Properties

High-temperature resistance

Performance under extreme conditions

Copper pipe coils with white PE insulation exhibit remarkable high-temperature resistance characteristics, ensuring optimal performance even in the most demanding environments. The inherent properties of copper enable these coils to withstand elevated temperatures without compromising efficiency or structural integrity. This resilience is essential for maintaining consistent HVAC operations and preventing potential system failures due to thermal stress.

When subjected to extreme conditions, such as fluctuating temperatures or prolonged exposure to heat sources, copper pipe coils with white PE insulation demonstrate exceptional durability and reliability. Their ability to adapt to varying environmental factors while maintaining peak performance levels highlights the superior quality of these components. This reliability factor is crucial for ensuring long-term operational efficiency and minimizing maintenance requirements in HVAC systems.

UV resistance

Longevity and durability

The UV resistance of copper pipe coils with white PE insulation plays a vital role in enhancing their longevity and overall durability. Exposure to ultraviolet radiation can degrade materials over time, leading to premature wear and reduced effectiveness. However, the UV-resistant properties of these coils mitigate such risks by providing a protective barrier against harmful sun exposure.

This enhanced longevity and durability translate into extended service life for HVAC systems utilizing copper pipe coils with white PE insulation. By minimizing the effects of UV radiation on the components, these coils maintain their structural integrity and functional performance over an extended period. This longevity ensures sustained operational efficiency and cost-effectiveness for both residential and commercial air conditioning applications.

Recyclability

End-of-life disposal and recycling processes

The recyclability of copper pipe coils with white PE insulation underscores their eco-friendly design and sustainable impact on the environment. At the end of their service life, these coils can undergo efficient recycling processes that recover valuable materials for reuse in various industries. This closed-loop approach minimizes waste generation and supports circular economy principles.

During end-of-life disposal, proper recycling procedures ensure that copper pipe coils with white PE insulation are processed in an environmentally responsible manner. By separating recyclable components from non-recyclable elements, waste management facilities can maximize resource recovery while minimizing environmental impact. These recycling processes contribute to reducing overall carbon footprint associated with HVAC system components, aligning with sustainable practices in the construction industry.

Sustainability Practices

Manufacturing processes

Implementing environmentally friendly production methods is paramount in the HVAC industry to uphold sustainable practices. By integrating eco-conscious approaches into manufacturing processes, companies can minimize their environmental impact and promote resource efficiency. Utilizing advanced technologies and renewable energy sources during production enhances the overall sustainability of twin copper pipe coils with white PE insulation.

Incorporating sustainable materials and reducing carbon emissions are key objectives in environmentally friendly production methods. By sourcing raw materials responsibly and optimizing manufacturing techniques, HVAC manufacturers can contribute to a greener future. Implementing energy-efficient practices and waste reduction strategies further solidify the commitment to sustainable manufacturing processes.

Installation and maintenance

Adhering to best practices for reducing environmental impact is essential when installing and maintaining HVAC systems. Proper installation procedures ensure optimal performance and energy efficiency, ultimately reducing the system's overall environmental footprint. Regular maintenance checks help identify potential issues early on, preventing unnecessary energy consumption and promoting system longevity.

Prioritizing energy-efficient installations and routine maintenance schedules minimizes resource wastage and supports sustainable HVAC operations. By following industry guidelines and utilizing eco-friendly products, technicians can enhance system performance while lowering environmental impact. Educating consumers on sustainable usage practices also plays a crucial role in maintaining eco-conscious HVAC systems.

Future developments

Innovations in HVAC technology continue to drive advancements towards improved sustainability in the industry. From smart thermostats to energy-efficient cooling solutions, technological innovations offer new opportunities for enhancing environmental performance. Embracing these advancements paves the way for more sustainable HVAC systems that prioritize energy conservation and eco-friendliness.

The potential for improved sustainability lies in ongoing research and development efforts focused on eco-friendly HVAC solutions. By exploring alternative materials, enhancing system efficiency, and integrating renewable energy sources, the future of HVAC technology holds promising prospects for sustainability. Collaborative initiatives between industry stakeholders further accelerate progress towards greener heating and cooling solutions.

Highlighting the historical shift towards sustainable HVAC practices underscores the industry's commitment to eco-conscious solutions.

Embracing geothermal HVAC systems showcases a progressive approach to energy efficiency and reduced environmental impact.

Incorporating ERV systems not only enhances indoor air quality but also optimizes energy consumption for a greener future.

See Also

Key Advantages of Twin Copper Pipe Coils with Insulation

Maximize AC Efficiency with Copper Pipe Insulation Tips