Guide to Choosing Air Conditioning Copper Pipes

Enhancing air conditioning systems with the right copper pipes is crucial for optimal performance. This Guide blog post on Choosing the Right Air Conditioning Copper Pipes will delve into the nuances of selecting the ideal copper piping, catering to various HVAC needs. Copper pipes stand out for their durability, efficient heat conductivity, and compatibility with refrigerants, making them a top choice in the industry.

Understanding Copper Pipes

When it comes to Copper Pipes, understanding the various types and properties is essential for making informed decisions in HVAC systems. Let's explore the distinct characteristics that make Copper Pipes a preferred choice in air conditioning applications.

Types of Copper Pipes

Type K Copper Pipes

Type K Copper Pipes are known for their durability and high pressure handling capabilities, making them suitable for demanding HVAC environments.

Type L Copper Pipes

Type L Copper Pipes are recognized for their thick walls, providing excellent strength and reliability, ideal for refrigeration and air conditioning systems.

Type M Copper Pipes

With slightly thinner walls than Type L, Type M Copper Pipes offer versatility while maintaining robust performance in various HVAC settings.

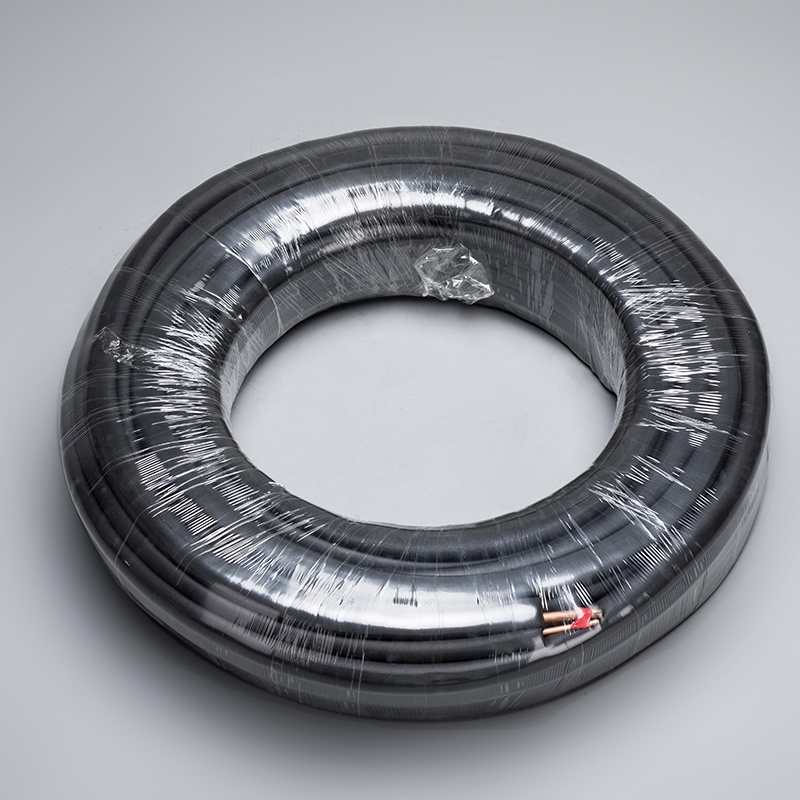

ACR Copper Pipes

ACR Copper Pipes are specifically designed for air conditioning and refrigeration applications, ensuring efficient heat transfer and long-term functionality.

Properties of Copper Pipes

Durability

The inherent strength of Copper Pipes ensures longevity and resilience against environmental factors, contributing to the overall reliability of HVAC systems.

Corrosion Resistance

Copper Pipes exhibit exceptional resistance to corrosion, safeguarding against degradation over time and maintaining consistent performance levels.

Thermal Conductivity

The superior thermal conductivity of Copper Pipes enables efficient heat transfer within air conditioning units, enhancing overall energy efficiency.

Common Applications in HVAC

Residential Air Conditioning

In residential settings, Copper Pipes are widely used for air conditioning installations due to their durability and compatibility with varying refrigerants.

Commercial Air Conditioning

Commercial HVAC systems benefit from the reliability of Copper Pipes, ensuring consistent performance under heavy usage demands in large-scale environments.

Industrial Air Conditioning

Industrial air conditioning units rely on the robust nature of Copper Pipes to withstand high pressures and temperatures, supporting continuous operation in industrial facilities.

Factors to Consider When Choosing Copper Pipes

Pipe Size and Diameter

Importance of Correct Sizing

Proper sizing of copper pipes is crucial for efficient air conditioning systems. Selecting the right diameter ensures optimal flow rates and pressure levels, contributing to the overall performance of HVAC units.

How to Measure Pipe Diameter

Measuring the diameter of copper pipes accurately is essential for determining the appropriate size for your air conditioning system. Utilize conversion tables or consult industry standards to identify the correct dimensions based on your specific requirements.

Wall Thickness

Impact on Durability

The thickness of copper pipes directly influences their durability and longevity in HVAC applications. Thicker walls provide enhanced strength and resistance to external factors, prolonging the lifespan of the piping system.

Choosing the Right Thickness for Your Needs

When selecting copper pipes, consider the environmental conditions and operating pressures within your air conditioning setup. Opt for a wall thickness that aligns with your system's demands, ensuring reliable performance under varying circumstances.

Compatibility with Refrigerants

Common Refrigerants Used

Understanding the compatibility of copper pipes with different refrigerants is essential for preventing chemical reactions or leaks within the system. Familiarize yourself with industry-approved refrigerants to make informed decisions regarding pipe selection.

Ensuring Compatibility

Prioritize selecting copper pipes that are specifically designed to work harmoniously with the refrigerants used in your air conditioning unit. Verify compatibility guidelines provided by manufacturers to maintain system efficiency and prevent potential issues.

Installation Environment

Indoor vs. Outdoor Use

Copper pipes are versatile components suitable for both indoor and outdoor applications, adapting to various environmental conditions effortlessly.

When considering indoor use, copper pipes excel in residential settings, ensuring reliable water supply and efficient HVAC systems without compromising on durability.

In contrast, outdoor environments pose unique challenges where copper pipes demonstrate resilience against harsh weather conditions and external elements.

The adaptability of copper pipes makes them ideal for diverse installations, guaranteeing consistent performance whether indoors or outdoors.

Environmental Factors to Consider

Environmental considerations play a crucial role in determining the suitability of copper pipes for specific applications, emphasizing the importance of assessing factors like temperature variations and exposure to moisture.

Understanding the impact of environmental elements on copper piping helps in selecting the right type and thickness to withstand varying conditions effectively.

Whether installed in humid climates or exposed to extreme temperatures, copper pipes offer exceptional resistance to environmental stressors, ensuring long-term functionality with minimal maintenance requirements.

By evaluating environmental factors meticulously, users can maximize the longevity and performance of their air conditioning systems with the appropriate selection of copper pipes.

Installation and Maintenance Tips

Proper Installation Techniques

To ensure the longevity and efficiency of your air conditioning system, proper installation techniques for copper pipes are paramount. Expertly executed installations not only guarantee optimal performance but also minimize the risk of potential issues down the line.

Begin by meticulously cutting and bending copper pipes to fit the specific requirements of your HVAC setup. Precision in these initial steps is crucial for seamless integration and functionality.

When it comes to joining methods, options like soldering and brazing offer reliable connections that withstand the demands of air conditioning systems. These techniques ensure secure fittings that promote efficient operation.

Maintenance Best Practices

Regular maintenance is key to preserving the integrity of your copper piping system and preventing costly repairs. By implementing consistent upkeep practices, you can extend the lifespan of your air conditioning unit significantly.

Conduct regular inspections to identify any signs of wear, leaks, or damage in your copper pipes. Timely detection allows for prompt intervention, mitigating potential issues before they escalate.

Emphasize cleaning and preventing corrosion as part of your maintenance routine. Keeping copper pipes free from debris and corrosion buildup enhances their performance and safeguards against operational disruptions.

Troubleshooting Common Issues

Inevitably, air conditioning systems may encounter challenges that require swift resolution to maintain optimal functionality. Familiarizing yourself with common issues enables proactive troubleshooting measures for uninterrupted cooling comfort.

Start by identifying leaks promptly to prevent water damage or refrigerant loss within your HVAC system. Pinpointing the source of leaks facilitates targeted repairs, ensuring continued efficiency.

Address blockages effectively by determining the cause and implementing appropriate solutions to restore proper airflow in your air conditioning setup. Swift action minimizes disruptions and preserves system performance.

Expert Testimony:

Benjamin Franklin Plumbing

When most people get a leaky or broken copper pipe in their house, they call a plumber without a second thought. After all, using a soldering gun to patch the water supply line back together is a lot trickier than simple plumbing repair jobs like replacing a faucet. However, with the right tools and some DIY handy-person skills, you can take care of the job yourself and save the cost of a repair bill. Read on for tips on how to solder copper pipes together.

In conclusion, ensuring the correct selection of copper pipes is paramount for optimal air conditioning performance. The durability and efficiency of copper piping significantly impact HVAC systems' functionality. By applying the provided insights on types, properties, and installation considerations, readers can enhance their air conditioning setups effectively. Remember, choosing the right copper pipes tailored to specific requirements is key to long-term system reliability and performance excellence. Your informed decisions today will pave the way for efficient cooling comfort tomorrow. Feel free to share your thoughts or inquire further!

See Also

Benefits of Opting for Copper Tubing in Air Conditioning

The Importance of Copper Piping for Effective Air Conditioning

Transforming Air Conditioning with Copper Piping