Your Guide to Choosing the Best Air Conditioning Pipe Materials

Selecting the appropriate pipe materials for air conditioning systems is crucial in ensuring optimal performance and longevity. With a variety of materials available, including copper, aluminum, PVC, and PEX, understanding their unique properties is essential. This Guides blog post on Using Copper Pipes in Air Conditioning Systems aims to empower readers with the knowledge needed to make well-informed decisions when choosing air conditioning pipe materials.

Understanding Air Conditioning Pipe Materials

When considering the types of pipe materials for air conditioning systems, it is essential to evaluate the unique properties and advantages they offer. Here, we delve into the characteristics of Copper Pipes, Aluminum Pipes, PVC Pipes, and PEX Pipes to provide a comprehensive overview for informed decision-making.

Types of Pipe Materials

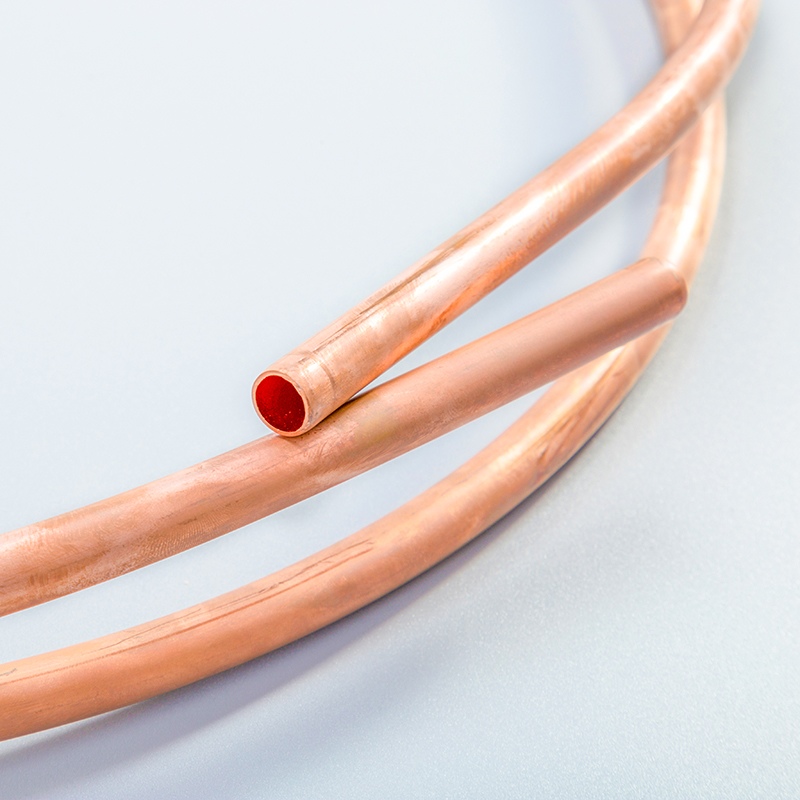

Copper Pipes

Copper Pipes are renowned for their versatility in various HVAC applications, including transporting hot water, chilled water, and refrigerants. They exhibit exceptional corrosion resistance, making them ideal for long-term use.

The strength of Copper allows for flexibility without compromising durability. This feature is particularly beneficial in installations where bending is required without risking pipe integrity.

Aluminum Pipes

Information on Aluminum Pipes is limited; however, it is worth noting that aluminum is a lightweight material with decent thermal conductivity properties.

PVC Pipes

PVC Pipes, a cost-effective alternative to traditional materials like copper, offer practicality in underground applications due to their corrosion-resistant nature. While not as robust as copper, they serve well in specific environments.

PEX Pipes

Details on PEX Pipes were not found; however, PEX tubing has gained popularity in replacing copper tubing for cold and hot water applications due to its flexibility and ease of installation.

Factors to Consider When Choosing Pipe Materials

Durability

The durability of pipe materials directly impacts the longevity and reliability of an air conditioning system. Opting for materials like copper ensures resilience against environmental factors and wear over time.

Cost

While cost plays a significant role in decision-making, it is crucial to balance initial expenses with long-term benefits. Materials like PVC may offer cost savings upfront but could require more frequent maintenance compared to copper.

Ease of Installation

Considering the ease of installation can streamline the construction process and reduce labor costs. Copper pipes are known for their malleability, allowing for straightforward installations even in complex configurations.

Compatibility with Refrigerants

Ensuring that chosen pipe materials are compatible with specific refrigerants used in air conditioning systems is paramount. Copper's chemical stability makes it an excellent choice for various refrigerant types commonly employed today.

Environmental Impact

Evaluating the environmental impact of pipe materials involves assessing factors such as recyclability and sustainability. Opting for eco-friendly options like PVC can contribute positively to green initiatives within HVAC projects.

Comparing Different Pipe Materials

Performance Comparison

Thermal Conductivity

Copper pipes exhibit superior thermal conductivity compared to other materials commonly used in air conditioning systems.

Aluminum pipes, while lightweight, may not offer the same level of thermal efficiency as copper.

PVC pipes have lower thermal conductivity than both copper and aluminum, impacting their heat transfer capabilities.

Corrosion Resistance

Copper pipes are highly resistant to corrosion, making them a durable choice for air conditioning applications.

Aluminum pipes are more susceptible to corrosion than copper, especially in environments with high humidity levels.

PVC pipes excel in corrosion resistance when exposed to moisture or chemicals, ensuring long-term reliability.

Flexibility

Copper pipes provide excellent flexibility without compromising strength, allowing for easy installation in various configurations.

Aluminum pipes offer moderate flexibility but may be prone to damage if bent repeatedly during installation.

PVC pipes are inherently flexible, making them suitable for applications that require bending around obstacles or tight spaces.

Cost Analysis

Initial Costs

Copper pipes typically have higher initial costs due to the material's quality and durability benefits.

Aluminum pipes are generally more cost-effective upfront but may incur higher maintenance expenses over time.

PVC pipes are the most budget-friendly option initially, making them attractive for projects with strict financial constraints.

Long-term Maintenance Costs

Copper pipes boast minimal maintenance requirements, reducing long-term costs associated with repairs or replacements.

Aluminum pipes may require more frequent maintenance due to their lower corrosion resistance compared to copper.

PVC pipes often necessitate periodic inspections and potential replacements over time, increasing maintenance expenses.

Installation Considerations

Required Tools and Equipment

Installing copper pipes may require specialized tools such as pipe benders and cutters to ensure precise fittings and connections.

Aluminum pipe installations typically involve standard plumbing tools but may need additional care during handling to prevent damage.

Working with PVC pipes demands basic cutting and solvent welding equipment for secure joints and leak-free installations.

Installation Time

The installation of copper pipes can be time-consuming due to the precision required for fittings and soldering processes.

Installing aluminum pipes is relatively quicker than copper installations but still requires attention to detail for proper alignment and sealing.

3.* PVC* pipe installations are known for their quick setup times thanks to simple jointing methods like solvent welding or compression fittings.

Skill Level Required

1.* Copper* pipe installations demand a higher skill level due to soldering techniques needed for secure connections and leak prevention.

2.* Aluminum* pipe installations can be managed by individuals with intermediate plumbing skills given proper guidance on handling the material safely.

3.* PVC* pipe installations are beginner-friendly, requiring basic knowledge of cutting and joining methods for successful setups.

Practical Tips for Selecting Pipe Materials

When deciding on the most suitable pipe materials for air conditioning systems, it is essential to assess specific needs accurately. By considering Climate Considerations and System Size and Capacity, individuals can make informed choices that align with their requirements.

Assessing Your Specific Needs

To begin, evaluating Climate Considerations is crucial in determining the optimal pipe material for air conditioning systems. Understanding the environmental factors such as temperature variations and humidity levels can guide the selection process effectively. By analyzing these elements, individuals can choose materials that withstand the climate challenges and ensure long-term performance.

In addition to climate factors, assessing System Size and Capacity plays a significant role in selecting pipe materials. The size of the air conditioning system and its cooling capacity influence the type of pipes needed for efficient operation. By considering these aspects, individuals can match the pipe materials to the system specifications, promoting seamless functionality and performance.

Consulting with Professionals

Seeking guidance from HVAC Technicians is highly recommended when choosing pipe materials for air conditioning systems. HVAC experts possess specialized knowledge and experience in selecting materials that best suit specific requirements. Consulting professionals ensures that individuals receive expert advice tailored to their unique needs, leading to optimal outcomes in system performance and longevity.

Furthermore, engaging with reputable Suppliers and Manufacturers can provide valuable insights into the latest advancements in pipe materials for air conditioning applications. Suppliers offer access to a wide range of products, allowing individuals to explore various options based on quality, durability, and compatibility with their systems. Collaborating with manufacturers ensures access to high-quality materials that meet industry standards and regulations.

Real-life Examples and Case Studies

Examining Residential Installations offers practical insights into the application of different pipe materials in home air conditioning systems. Real-life examples showcase how specific materials perform under varying conditions, highlighting their advantages and considerations for residential settings. By studying residential installations, individuals can gain a better understanding of which pipe materials best suit their home cooling needs.

Similarly, exploring Commercial Installations provides valuable case studies on utilizing different pipe materials in large-scale air conditioning projects. Commercial settings present unique challenges that require durable and efficient piping solutions to maintain optimal indoor comfort levels. Analyzing successful commercial installations offers lessons on selecting appropriate materials for complex HVAC systems, ensuring reliability and performance in commercial environments.

Recap of Key Points Discussed:

Copper and steel are the primary metals used for HVAC piping, with copper favored for smaller pipes due to its corrosion resistance and durability.

Understanding the unique properties of Copper Pipes, Aluminum Pipes, PVC Pipes, and PEX Pipes is crucial for informed decision-making.

Factors like Durability, Cost, and Compatibility with Refrigerants play significant roles in selecting the best pipe materials.

Final Recommendations for Choosing the Best Pipe Materials:

Prioritize durability and corrosion resistance when selecting pipe materials to ensure long-term reliability.

Consider the initial costs versus long-term maintenance expenses to make cost-effective choices.

Opt for materials like copper that offer superior thermal conductivity and flexibility for efficient air conditioning systems.

Encouragement to Consult with Professionals:

Seek advice from HVAC technicians and suppliers to receive personalized recommendations based on your specific needs. Professional guidance ensures optimal performance and compatibility with your air conditioning system requirements.

Invitation for Readers:

Share your experiences in choosing air conditioning pipe materials and feel free to ask questions or seek further clarification on any aspect discussed in this guide. Your feedback contributes to a collaborative learning environment within the HVAC community.

See Also

Benefits of Opting for Copper Tubing in Air Conditioning

The Importance of Copper Piping for Effective Air Cooling

Expert Tips for Copper Pipe Connections: A DIY Handbook