Guide to Technical Standards for Copper Aluminum Pipe Connections

In the realm of HVAC components, adhering to technical standards for copper aluminum connecting pipes is paramount. Understanding the evolution of these connections provides insight into their significance. This guide delves into the properties and applications of copper and aluminum pipes, emphasizing the challenges posed by compatibility issues. By exploring international and national standards, this comprehensive resource aims to enhance your knowledge of connection methods like compression fittings and brazing techniques. Join us on a journey through testing procedures, quality assurance measures, and insightful comparisons in the world of pipe connections.

Materials and Systems Involved

Copper Pipes

Properties and Characteristics

Copper tubing is renowned for its exceptional thermal conductivity, making it ideal for various applications.

Its malleability allows for easy shaping and bending without compromising structural integrity.

The inherent antimicrobial properties of copper contribute to a hygienic environment in water distribution systems.

Common Applications

Water Distribution Systems

Oil Fuel Transfer Lines

Non-flammable Medical-gas Systems

Refrigerant Line in HVAC Systems

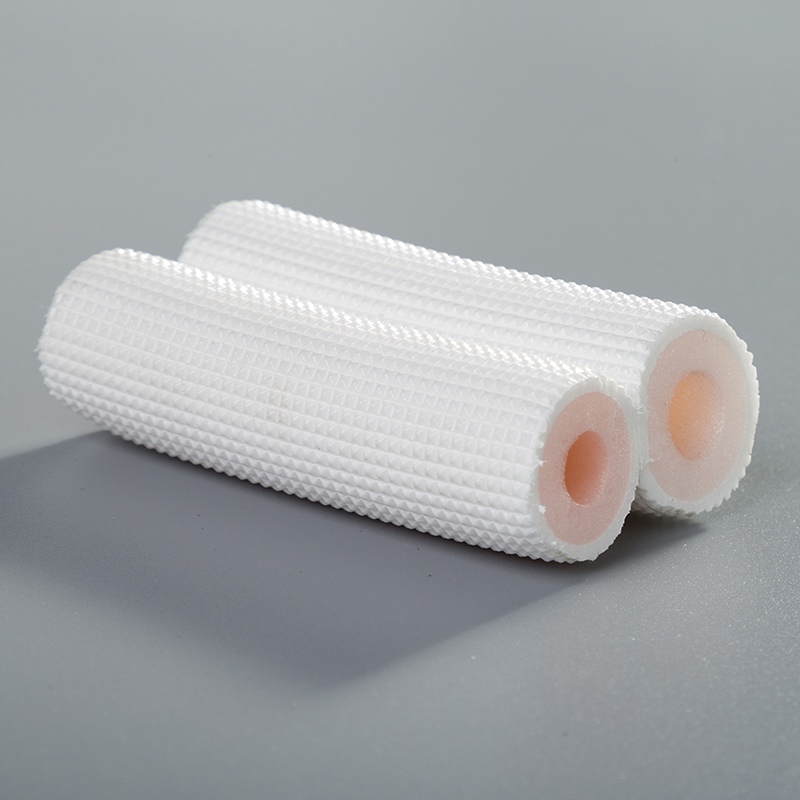

Aluminum Pipes

Properties and Characteristics

Aluminum pipes are lightweight yet durable, providing a corrosion-resistant solution for diverse environments.

Their high strength-to-weight ratio makes them suitable for applications requiring both reliability and efficiency.

The excellent thermal conductivity of aluminum ensures optimal heat transfer in HVAC components.

Common Applications

Air Conditioning Systems

Heat Exchangers

Refrigeration Units

Compatibility and Challenges

Corrosion Issues

"HVAC manufacturers evaluating the use of aluminum components need to consider the best method for joining parts-such as evaporator and condenser coils-to secondary copper lines or assemblies."

Thermal Expansion Differences

Several joining methods can be used, including adhesives, mechanical joining, ultrasonic joining, soldering, and brazing.

Technical Standards and Guidelines

International Standards

ISO Standards

ISO standards play a crucial role in ensuring the quality and compatibility of copper aluminum pipe connections. These standards cover a wide range of specifications for pipe, tube, and fittings, catering to various applications in HVAC systems.

The ISO 9001 certification signifies adherence to stringent quality management practices, guaranteeing reliability and performance in copper aluminum connections.

Implementing ISO standards fosters consistency and efficiency in the production and installation of these essential components.

ASTM Standards

ASTM standards, such as those for pipes, valves, and fittings, provide comprehensive guidelines on pressure-temperature ratings, materials, dimensions, testing procedures, and marking requirements.

The ASTM B42 specification ensures uniformity in the dimensions of seamless copper pipes, promoting interchangeability and ease of use in diverse applications.

By following ASTM standards, manufacturers can enhance product safety, durability, and overall system integrity.

National Standards

ANSI Standards

ANSI standards establish critical benchmarks for the design, construction, and performance of copper aluminum pipe connections. These standards encompass a wide array of technical aspects to ensure compliance with industry best practices.

Adhering to ANSI requirements guarantees that installations meet safety regulations while optimizing operational efficiency within HVAC systems.

The adoption of ANSI standards reflects a commitment to excellence and precision in the fabrication and assembly of copper aluminum components.

Local Building Codes

Local building codes serve as essential references for regulating the installation and maintenance of copper aluminum pipe connections within specific geographic regions.

Compliance with local codes is imperative to uphold structural integrity, prevent hazards, and promote environmental sustainability in HVAC applications.

By aligning with local building regulations, stakeholders can mitigate risks associated with non-compliance while upholding community safety standards.

Connection Methods and Techniques

Mechanical Connections

Compression Fittings

Compression fittings provide a reliable method for connecting copper and aluminum pipes without the need for soldering or brazing.

The compression fitting consists of three parts: a compression nut, a compression ring (ferrule), and the body.

To create a leak-proof joint, insert the pipe into the fitting, ensuring it reaches the tube stop, then tighten the nut securely.

Flare Fittings

Flare fittings are commonly used to connect copper tubing in HVAC systems due to their secure and durable design.

The flare fitting process involves flaring the end of the pipe at a 45-degree angle to create a sealing surface.

Once flared, the pipe is connected to another component by threading it into place, providing a tight seal against leaks.

Brazing and Soldering

Suitable Alloys

Brazing and soldering are essential techniques for joining copper and aluminum pipes effectively.

Commonly used alloys include silver-based solders or brazing materials with flux cores for improved bonding.

These alloys offer high strength joints that withstand thermal stresses in HVAC applications.

Process Steps

Prepare the surfaces to be joined by cleaning them thoroughly with a wire brush or emery cloth.

Apply flux to both surfaces to prevent oxidation during heating and promote alloy flow.

Heat the joint evenly using a torch until the solder or brazing material melts and flows into the connection.

Welding Techniques

TIG Welding

TIG welding, also known as Gas Tungsten Arc Welding (GTAW), is suitable for precise welding of thin copper and aluminum components.

This technique uses a non-consumable tungsten electrode to create an arc that fuses the base metals together.

TIG welding provides clean welds with minimal spatter, ideal for intricate joints in HVAC systems.

MIG Welding

MIG welding, or Gas Metal Arc Welding (GMAW), offers a faster welding process suitable for thicker sections of copper and aluminum pipes.

In MIG welding, a consumable wire electrode feeds through a welding gun, creating an arc that melts both the wire and base metals.

This method is efficient for high-volume production while maintaining strong weld integrity.

Testing and Quality Assurance

Pressure Testing

Procedures

Conducting pressure tests is essential to validate the integrity of technical standards for copper aluminum connecting pipes.

Begin by isolating the section to be tested and securely closing all access points to prevent leaks.

Gradually increase the pressure using a hydraulic pump while monitoring for any fluctuations or drops that may indicate leaks.

Maintain the pressure for a specified duration as per industry guidelines to assess the system's stability.

Record and analyze the test results meticulously, noting any deviations from expected values for further investigation.

Safety Precautions

Prioritize safety measures during pressure testing to mitigate potential hazards associated with high-pressure systems.

Equip personnel with appropriate personal protective equipment, including safety goggles and gloves, to prevent injuries.

Ensure that all testing equipment is in optimal condition and regularly calibrated to guarantee accurate readings.

Implement clear communication protocols among team members involved in the testing process to coordinate actions effectively.

Establish emergency response procedures in case of unexpected incidents, emphasizing swift action and prioritizing personnel well-being.

Leak Detection

Methods

Detecting leaks in copper aluminum pipe connections demands precision and thoroughness to uphold technical standards effectively.

Utilize advanced leak detection technologies such as ultrasonic sensors or thermal imaging cameras for efficient identification of potential leak points.

Conduct visual inspections along with pressure decay tests to pinpoint areas of concern accurately.

Employ tracer gases or leak detection solutions that react when exposed to escaping fluids, aiding in locating even minor leaks swiftly.

Tools and Equipment

Invest in high-quality leak detection tools like electronic leak detectors or bubble solutions that enhance accuracy during inspection processes.

Use pressure gauges and flow meters to monitor system performance continuously while conducting leak detection assessments.

Leverage acoustic listening devices that amplify sound variations caused by escaping fluids, enabling precise localization of leaks within intricate piping systems.

Inspection and Certification

Visual Inspection

Visual inspections serve as fundamental assessments ensuring compliance with established technical standards for copper aluminum pipe connections.

Inspectors should examine joints, fittings, and pipe surfaces for signs of corrosion, deformation, or irregularities that may compromise system integrity.

Document findings systematically through photographs or detailed reports to facilitate comprehensive analysis and decision-making processes.

Certification Requirements

Obtaining certification signifies adherence to rigorous quality assurance protocols governing copper aluminum pipe connections within HVAC systems.

Certification bodies evaluate installations based on predetermined criteria related to material quality, installation practices, and system performance benchmarks.

Compliance with certification requirements demonstrates a commitment to excellence in maintaining industry best practices for safe and reliable piping systems.

Results and Comparisons

Performance Metrics

Durability

Copper and aluminum pipes exhibit exceptional durability in various HVAC applications, ensuring long-term reliability.

Aluminum's corrosion-resistant properties enhance the longevity of pipe connections, reducing maintenance needs.

The durability of copper pipes is renowned for withstanding high temperatures and pressures, making them a robust choice for critical systems.

Efficiency

When comparing copper and aluminum pipes, efficiency plays a crucial role in determining the optimal choice for specific applications.

Aluminum's lightweight nature contributes to energy efficiency by reducing the overall weight of HVAC components.

Copper's superior thermal conductivity enhances system efficiency by facilitating rapid heat transfer, improving overall performance.

Cost Analysis

Material Costs

Copper Pipes:

The initial cost of copper pipes may be higher than other materials; however, their long lifespan and minimal maintenance requirements offset this expense over time.

Investing in high-quality copper tubing ensures reliability and longevity, reducing the need for frequent replacements.

Aluminum Pipes:

Aluminum piping offers cost-effective solutions due to its lightweight construction, which simplifies installation processes and reduces labor costs.

While initial material costs may be lower compared to copper, aluminum's durability ensures long-term savings through reduced maintenance expenses.

Labor Costs

Installation Efficiency:

Copper and aluminum pipes differ in terms of installation complexity, impacting labor costs associated with system assembly.

Copper's malleability allows for easy shaping and bending during installation, potentially reducing labor hours required for intricate configurations.

Maintenance Expenses:

Aluminum's corrosion resistance minimizes the need for frequent maintenance checks or replacements, leading to lower labor costs over the system's lifecycle.

Efficient installation methods such as press-connect fittings can further streamline labor expenses by accelerating assembly processes.

Case Studies

Successful Implementations

In a recent case study comparing different pipe materials for HVAC applications, copper emerged as the preferred choice due to its superior durability and thermal conductivity.

Several successful implementations showcased how copper aluminum pipe connections met stringent technical standards while delivering reliable performance in diverse environments.

Lessons Learned

Through extensive industry research and practical applications, professionals have learned valuable insights about optimizing joint integrity in copper aluminum pipe connections.

Emphasizing proper testing procedures and adherence to technical standards is essential to prevent leaks or structural failures in HVAC systems over time.

In the ever-evolving Pipe Fittings Market, technological advancements and sustainability goals are shaping the landscape. The market's growth trajectory aligns with the demand for customized solutions, driving seamless connectivity in modern infrastructure worldwide. As consumer behavior analysis and market dynamics provide crucial insights, adherence to technical standards for copper aluminum connecting pipes remains paramount. Technological innovation will further optimize product performance, expanding its utility in downstream applications. The future holds promising trends and advancements that will enhance joint integrity and system efficiency, ensuring a robust foundation for HVAC components.

See Also

The Definitive Copper Pipe Types and Soldering Handbook

Key Safety Rules for Installing Copper Pipe Coils

Key Safety Rules for Twin Copper Pipe Installations