How Copper Market Trends Shape Air Conditioning System Prices

Copper stands as a cornerstone in the HVAC industry, pivotal for various applications due to its exceptional thermal conductivity and durability. This blog delves into the intricate relationship between copper market trends and air conditioning system prices. By analyzing the impact of fluctuating copper prices on HVAC manufacturers, we aim to provide valuable insights into the dynamics shaping product costs. The blog structure will navigate through the significance of copper, current price trends, manufacturer responses, material shifts, and future projections. This comprehensive guide will help you understand How Copper Price Changes Influence Air Conditioning System Costs.

The Role of Copper in Air Conditioning Systems

Copper, renowned for its exceptional properties, plays a vital role in air conditioning systems. Its conductivity and efficiency are unmatched, allowing for optimal heat transfer within HVAC units. Moreover, the durability and longevity of copper components ensure the longevity and reliability of air conditioning systems.

Essential Properties of Copper

Conductivity and Efficiency: Copper's high thermal conductivity enables efficient heat exchange, contributing to the overall performance of air conditioning systems.

Durability and Longevity: The robust nature of copper ensures that HVAC components made from this material have a long lifespan, reducing maintenance costs over time.

Copper Components in HVAC Systems

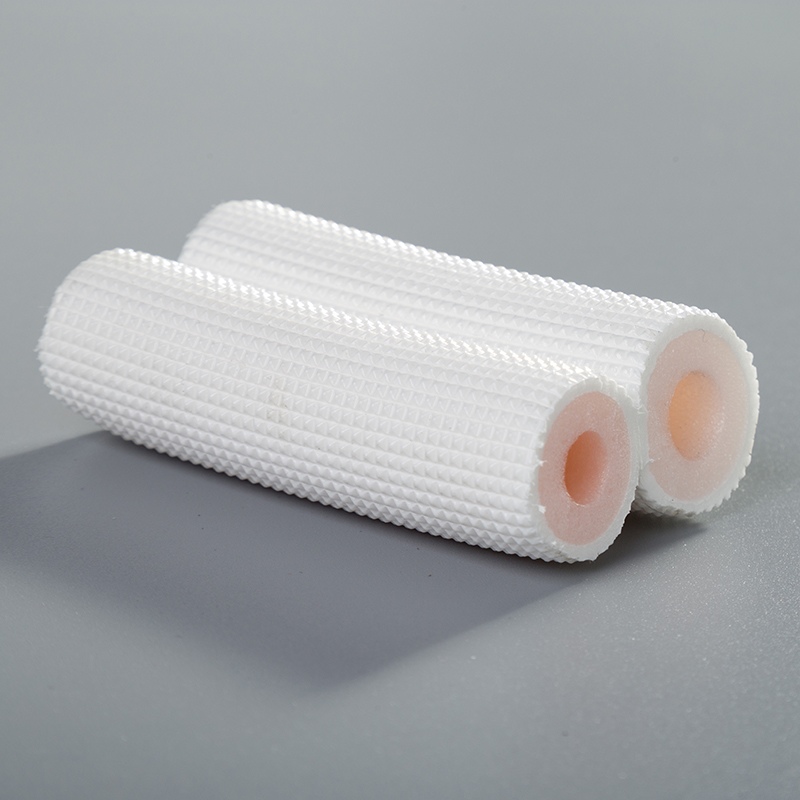

Tubing and Piping: Copper tubing is widely used in HVAC systems due to its corrosion resistance and malleability, allowing for seamless installation and optimal refrigerant flow.

Heat Exchangers: Copper heat exchangers are integral to the cooling process, efficiently transferring heat from the indoor air to the refrigerant.

Electrical Wiring: Copper wiring is essential for electrical connections within air conditioning units, ensuring reliable power distribution for smooth operation.

Current Trends in Copper Prices

Global Demand and Supply Dynamics

The global market for copper is influenced by the interplay between major copper producing countries and industrial demand drivers. Countries like China, Chile, and Peru have been pivotal in shaping the supply side of the market. On the other hand, industries such as electronics, construction, and automotive play a significant role in driving demand for this essential metal.

Recent Price Fluctuations

Analyzing historical price data reveals intriguing patterns in copper pricing over the years. The fluctuations are not merely random but are often tied to specific events or market dynamics. Factors such as geopolitical tensions, economic policies, and technological advancements have been instrumental in influencing recent trends in copper prices.

Impact of Rising Copper Prices on HVAC Manufacturers

The surge in copper prices, expected to rise by more than 75% over the next two years, directly impacts HVAC manufacturers. The fluctuations in copper prices can significantly affect the manufacturing costs of HVAC line sets, posing pricing and profit margin challenges for producers.

Increased Production Costs

Material Cost Breakdown:

Technological advancements have influenced the manufacturing costs of AC copper pipes per foot. These improvements play a crucial role in determining the final pricing structure of air conditioning systems.

Impact on Manufacturing Processes:

The steady increase in copper prices from the 1970s through the 1990s reflects the growing demand for this versatile metal. This trend directly affects manufacturers, compelling them to reassess their production processes to mitigate cost implications.

Pricing Strategies and Market Response

Cost-Passing to Consumers:

Recent increases in copper prices could pose a significant challenge for the U.S. construction industry and the copper market. The economic burden on building projects may escalate if manufacturers of copper-containing HVAC systems feel compelled to boost their pricing strategies.

Competitive Market Adjustments:

With rising copper prices impacting production costs, HVAC manufacturers are faced with tough decisions regarding pricing strategies. Competitive market adjustments become essential as companies navigate through the challenges posed by fluctuating material costs.

Shift to Alternative Materials

Introduction of Aluminum in HVAC Systems

The introduction of aluminum as an alternative material in HVAC systems has sparked a significant shift within the industry. Manufacturers are increasingly exploring the use of aluminum components, particularly in air conditioners and heat exchangers, as a strategic response to the escalating copper prices. This transition is driven by the cost-effectiveness and sustainability that aluminum offers compared to traditional copper materials.

Comparative Analysis: Copper vs. Aluminum

Cost-Effectiveness: Aluminum presents a compelling cost advantage over copper, making it an attractive choice for HVAC manufacturers looking to optimize production expenses without compromising quality.

Energy Efficiency: The lightweight nature of aluminum contributes to enhanced energy efficiency in air conditioning systems, promoting eco-friendly practices and reducing operational costs.

Durability: Despite its lighter weight, aluminum demonstrates remarkable durability and resilience, ensuring long-term performance and reliability in HVAC applications.

Benefits and Drawbacks of Aluminum

Environmental Impact: The recyclability of aluminum aligns with sustainable practices, reducing waste and supporting resource conservation efforts within the HVAC sector.

Regulatory Compliance: Aluminum's compliance with environmental regulations positions it as a favorable material choice for manufacturers seeking to meet industry standards while maintaining operational efficiency.

Industry Adoption and Trends

The adoption of aluminum within the HVAC industry is gaining momentum as manufacturers recognize the benefits it offers in mitigating the impact of rising copper prices. Through case studies showcasing successful transitions to aluminum components, industry players are illustrating the feasibility and advantages of this material shift.

Case Studies of Manufacturers

HVAC Manufacturer A: Embracing aluminum tubing in their air conditioning units led to a 15% reduction in production costs while maintaining product quality standards. This strategic move not only enhanced cost-effectiveness but also positioned the company as an innovator in sustainable manufacturing practices.

HVAC Manufacturer B: By incorporating aluminum fins in their heat exchangers, this manufacturer achieved a 20% increase in energy efficiency ratings compared to traditional copper fins. The market response was overwhelmingly positive, highlighting consumer acceptance of environmentally conscious HVAC solutions.

Market Acceptance and Consumer Perception

The market's acceptance of aluminum-based HVAC systems continues to grow as consumers recognize the value proposition offered by these innovative products. With a focus on sustainability, energy efficiency, and cost-effectiveness, aluminum components are reshaping consumer perceptions regarding air conditioning system technologies.

Projected Future Trends in Copper Prices

Economic and Geopolitical Factors

Trade Policies and Tariffs

The imposition of trade policies and tariffs can significantly impact the global copper market, leading to fluctuations in prices and supply chain disruptions.

Countries engaging in trade disputes may resort to imposing tariffs on copper imports, further complicating the pricing dynamics for HVAC manufacturers.

Global Economic Outlook

The global economic outlook plays a crucial role in shaping future trends in copper prices, as economic growth rates and market stability directly influence demand for this essential metal.

Fluctuations in currency exchange rates and geopolitical tensions can create uncertainties that reverberate across the copper market, affecting air conditioning system costs.

Technological Advancements and Innovations

Recycling and Sustainable Practices

Embracing recycling initiatives and sustainable practices within the HVAC industry can mitigate the impact of rising copper prices by promoting resource conservation and reducing material waste.

Manufacturers incorporating recycled copper materials into their production processes demonstrate a commitment to environmental stewardship while addressing cost challenges.

New Material Developments

Ongoing advancements in material science are driving innovations towards developing alternative materials that offer cost-effective solutions for HVAC components.

Exploring new material developments such as composite alloys or hybrid solutions presents opportunities for HVAC manufacturers to diversify their product lines amidst fluctuating copper prices.

Fluctuating copper prices directly impact the manufacturing costs of HVAC line sets, leading to pricing and profit margin challenges for producers.

Seasonal variations and economic factors play a significant role in influencing copper pipe prices, affecting the production and pricing of essential components for air conditioning systems.

Rising copper prices could potentially result in budget overruns and project delays within the construction sector, posing challenges for accurate cost predictions.

The market players in the Copper Iron Tubes for HVAC-R Market face hurdles due to fluctuating raw material prices, particularly for copper, which can limit market growth.

See Also

The Advantages of Copper Tubing for Air Conditioning Systems

Exploring Future Innovations in Copper Tube Production for AC

Benefits of Opting for Copper Piping in Air Conditioning

The Impact of High-Quality Copper Piping on AC Systems

The Importance of Copper Piping for Effective Air Conditioning