How to Connect Copper Pipe to Galvanized Pipe - A Step-by-Step Guide

Can you connect copper pipe to galvanized pipe properly? Ensuring a reliable plumbing system is crucial. Failing to do so can lead to a host of issues, including leaks and potential contamination risks. This guide offers a comprehensive overview of the correct methods to achieve a secure and long-lasting connection between these two different materials. By following the step-by-step instructions provided, individuals can confidently tackle this task while maintaining the integrity of their plumbing infrastructure. Additionally, can you connect copper pipe to PEX? This guide will also cover the necessary steps to ensure a proper connection between copper and PEX pipes.

Tools and Materials

Essential Tools

Utilize a high-quality pipe cutter to ensure precise cuts on both copper and galvanized pipes.

Employ a sturdy wrench to securely fasten fittings without the risk of slippage.

A reliable soldering kit is essential for effectively joining copper pipes with other materials.

Required Materials

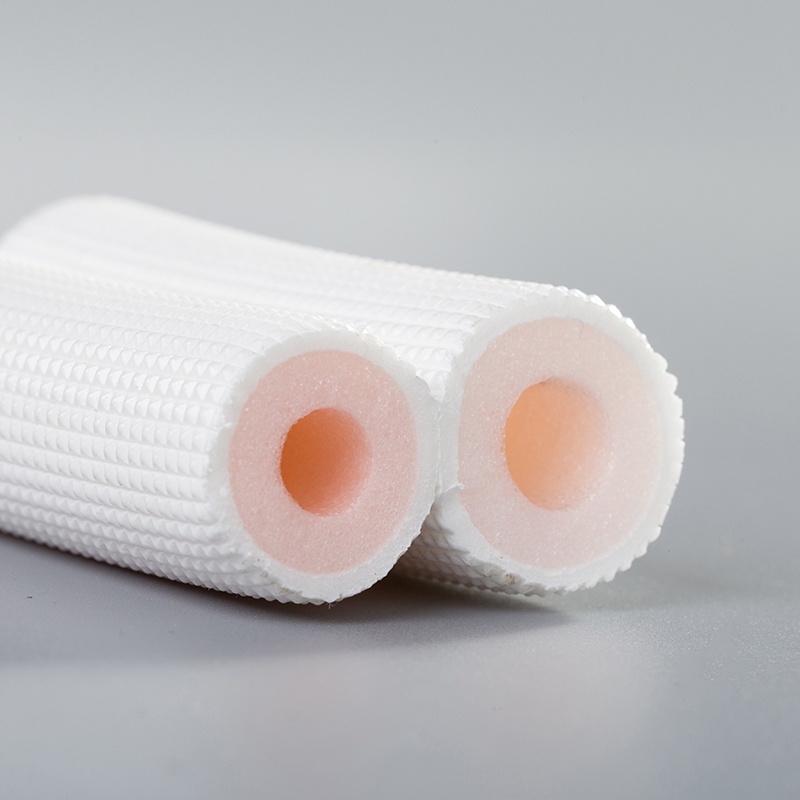

Incorporate a dielectric union to prevent corrosion when connecting copper and galvanized pipes.

Seal threaded connections effectively using Teflon tape to avoid leaks and ensure a tight fit.

Enhance joint durability by applying pipe dope, which provides additional sealing and lubrication properties.

Opt for brass fittings when transitioning between copper and galvanized pipes, as brass offers compatibility with both materials.

H&K Fabrication offers a wide selection of different pipe fitting tools that make pipe welding jobs quick and easy. They also provide various pipe fitting tool accessories to enhance the welding experience. The tools include Roll Out Wheels, Lathe Chucks, Pipefitting Squares, Jack Heads, and Bottle Hooks.

Step-by-Step Guide

Preparing the Pipes

Cutting the pipes

To initiate the process of connecting copper and galvanized pipes seamlessly, start by using a pipe cutter to make precise cuts on both types of pipes. This step is crucial in ensuring that the pipes are trimmed to the required length for a secure connection. Remember, accuracy in cutting will contribute to the overall stability of the joint.

Cleaning the ends

Once the pipes have been cut to size, proceed by cleaning the ends meticulously. Use a suitable cleaning tool to remove any debris, dirt, or oxidation present on the pipe surfaces. This cleaning process is essential as it promotes better adhesion and ensures a smooth transition between the copper and galvanized materials.

Connecting the Pipes

Attaching the dielectric union

The next vital step in this connection procedure is attaching the dielectric union. This specialized fitting plays a significant role in preventing corrosion between copper and galvanized pipes. Securely fasten the dielectric union to create a reliable barrier that inhibits any potential chemical reactions between these dissimilar metals.

Soldering the copper pipe

For a robust and enduring connection, proceed with soldering the copper pipe. Utilize your soldering kit efficiently to join the copper pipe with other components securely. The soldering process creates a strong bond that enhances the overall structural integrity of your plumbing system.

Threading the galvanized pipe

In parallel with soldering, it's essential to focus on threading the galvanized pipe effectively. This step involves creating threaded ends on your galvanized pipe using appropriate tools. Proper threading ensures compatibility with fittings and facilitates a secure attachment point for seamless integration into your plumbing network.

Finalizing the Connection

Applying Teflon tape

As you near completion of this intricate process, ensure to apply Teflon tape diligently. Wrapping Teflon tape around threaded connections provides an additional layer of protection against leaks and reinforces joint stability. Proper application of Teflon tape contributes significantly to maintaining a watertight seal within your plumbing system.

Tightening the fittings

With all components in place, focus on tightening the fittings securely. Utilize a wrench or suitable tool to ensure that all connections are snug and free from any play or looseness. Adequately tightened fittings are essential for maintaining pressure integrity throughout your plumbing setup.

Checking for leaks

To guarantee optimal performance post-installation, conduct thorough checks by inspecting for leaks along all connection points. Pressurize your system gradually and observe each joint closely for any signs of water seepage or drips. Identifying and addressing leaks promptly will help prevent potential water damage and ensure long-term reliability in your plumbing infrastructure.

Can You Connect Copper Pipe to Galvanized Pipe?

Understanding Compatibility

Risks of corrosion

Chlorine can degrade certain plumbing systems over time, causing material weakness and system defects.

FlowGuard CPVC minimizes biofilm growth and reduces potential for harmful bacteria compared to PPR.

Legionella growth can be caused by biofilm formation in plumbing pipes.

Importance of dielectric union

Different piping materials can be vulnerable to adverse effects from incompatible materials.

Galvanic corrosion and chemical compatibility failures can occur due to dissimilar materials or certain chemicals.

No documented programs exist to identify chemicals incompatible with PEX or PEX fittings.

Can You Connect Copper Pipe to PEX?

Differences in materials

When considering the connection between copper pipe and PEX, it is crucial to understand the differences in their material properties.

Copper pipes are known for their durability and resistance to high temperatures, making them suitable for various plumbing applications.

On the other hand, PEX pipes offer flexibility and ease of installation, particularly in challenging spaces where traditional rigid pipes may not fit easily.

Appropriate fittings

Selecting the right fittings is essential when connecting copper pipe to PEX to ensure a leak-free and secure joint.

Compression fittings are commonly used for connecting copper pipes, providing a tight seal without the need for soldering.

For PEX connections, crimp rings or clamp rings are popular choices, offering a reliable connection that withstands water pressure effectively.

Recap of the steps:

Ensure precise cuts on both copper and galvanized pipes using a pipe cutter.

Clean the ends meticulously to remove any debris or oxidation present on the pipe surfaces.

Attach the dielectric union securely to prevent corrosion between the two materials.

Solder the copper pipe efficiently to create a strong bond for structural integrity.

Thread the galvanized pipe effectively for compatibility with fittings.

Apply Teflon tape diligently to reinforce joint stability.

Tighten all fittings securely to maintain pressure integrity.

Importance of following guidelines:

Following these steps meticulously is crucial for a reliable and long-lasting connection between copper and galvanized pipes, ensuring a leak-free plumbing system.

Encouragement to seek professional help if needed:

If individuals encounter challenges or are unsure about any step in the process, seeking professional assistance can guarantee a successful connection without compromising the plumbing infrastructure's integrity.

See Also

Basic Instructions: Soldering a Copper Pipe for Newbies

Detailed Manual for Purchasing Copper Pipe Coils

Quick DIY Tutorial for Repairing a Split Copper Pipe

The Definitive Handbook on Copper Pipe Varieties and Soldering

Simple Techniques: Measuring Copper Pipe for DIY Achievement