How to Connect Plastic Pipes to Copper Pipes: A Step-by-Step Guide

Plastic and copper pipes are frequently used in plumbing systems due to their durability and reliability. How to connect plastic pipe to copper is a crucial skill for any DIY enthusiast or professional plumber. Understanding the various methods available is essential for successful installations. This blog will provide an insightful overview of these methods, guiding you through the process step by step. Additionally, it will highlight the necessary tools and materials required to ensure a seamless connection between how to connect plastic pipe to copper pipe.

Tools and Materials Needed

Essential Tools

Wrenches

Wrenches are essential tools for tightening and loosening nuts and bolts. They come in various sizes to fit different fasteners, providing a secure grip for effective installation.

Pipe Cutter

A pipe cutter is a handy tool designed to cut through pipes with precision. It ensures clean and smooth cuts, making the pipes ready for connection without any jagged edges that could affect the fitting process.

Teflon Tape

Teflon tape, also known as plumber's tape, is a versatile tool used to seal pipe threads effectively. By wrapping the tape around the male threads of fittings, it creates a tight seal that prevents leaks and enhances the overall connection quality.

Required Materials

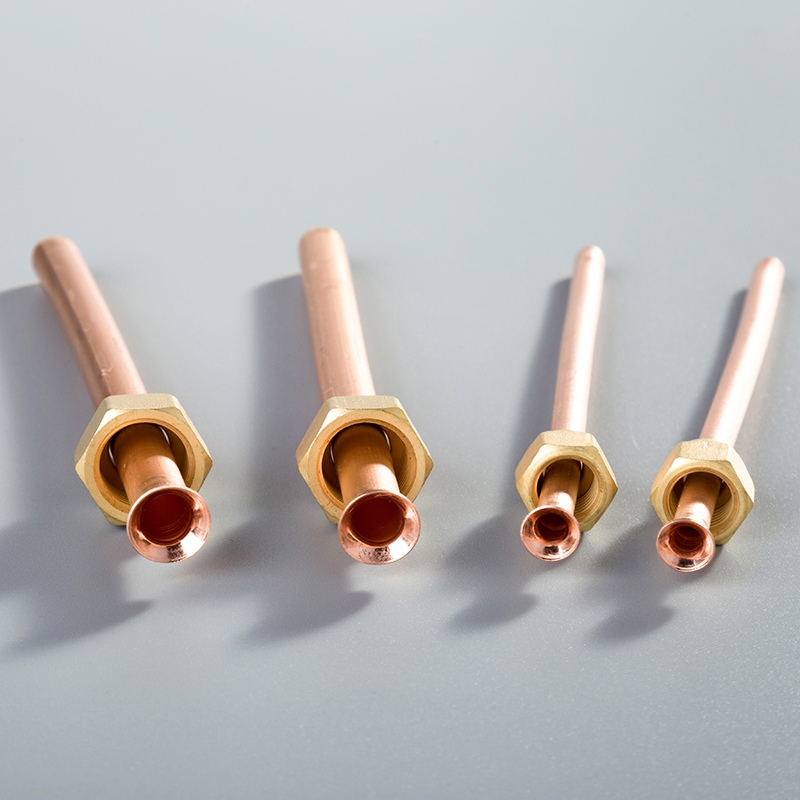

Compression Fittings

Compression fittings play a vital role in connecting plastic pipes to copper pipes securely. These fittings consist of a compression ring, threaded nut, and insert adapter, providing a reliable joint that withstands pressure and ensures long-term durability.

Epoxy Glue

Epoxy glue is a powerful adhesive commonly used for bonding plastic to copper pipes. By roughening the plastic surface before application, the epoxy forms a strong bond that can withstand varying temperatures and pressures within plumbing systems.

Threaded Adapters

Threaded adapters are versatile components used to connect different types of pipes seamlessly. By soldering these adapters onto copper pipes or using them with compression fittings, you can create leak-proof joints between plastic and copper pipes effortlessly.

Step-by-Step Guide

Preparing the Pipes

Cutting the Pipes

To begin, cut the plastic and copper pipes to the desired length using a pipe cutter. Ensure that the cuts are clean and precise to facilitate a smooth connection process.

Cleaning the Pipe Ends

Next, clean the ends of both pipes thoroughly to remove any dirt, debris, or rough edges. This step is crucial to ensure a secure and leak-free joint between the plastic and copper pipes.

Using Compression Fittings

Inserting the Pipe

Take the plastic pipe and insert it into the compression fitting's insert adapter. Make sure it goes in smoothly and securely to prepare for the next step.

Tightening the Compression Ring

Once the plastic pipe is inserted, use a wrench to tighten the compression ring onto the pipe. Ensure a snug fit by firmly securing the ring with the threaded nut.

Applying Epoxy Glue

Roughening the Plastic Surface

Before applying epoxy glue, roughen up the surface of the plastic pipe with sandpaper. This process creates tiny scratches that enhance adhesion and promote a stronger bond between the plastic and copper pipes.

Mixing and Applying the Glue

Follow the manufacturer's instructions to mix and apply epoxy glue onto the roughened surface of the plastic pipe. Press it firmly against the copper pipe to allow for proper bonding and curing.

Threaded Connections

Soldering the Copper Pipe

To ensure a secure and reliable connection between plastic and copper pipes, soldering the copper pipe is a common method used by professionals. This process involves heating the joint where the copper pipe meets the threaded adapter to melt solder, which then flows into the connection, creating a tight seal. By using a soldering torch, the copper pipe's end can be heated until it reaches the necessary temperature for the solder to bond effectively with both pipes.

Screwing the PVC Adapter

After successfully soldering the copper pipe, screwing in the PVC adapter is the next step in connecting plastic to copper pipes. The male threads of the PVC adapter should align perfectly with the female threads of the threaded adapter on the copper pipe. Using a wrench, tighten the PVC adapter securely onto the threaded adapter to create a leak-proof joint. This method ensures that both pipes are firmly connected and ready for use in plumbing systems without any risk of leaks or disconnections.

Tips and Troubleshooting

Common Issues

Leaks

Leaking pipes can lead to water damage and mold growth if not addressed promptly. To prevent leaks, regularly inspect plastic pipe and copper connections for any signs of moisture. Apply a small amount of epoxy glue or Teflon tape to the joint to reinforce the seal and prevent future leaks.

Loose Connections

Loose connections between plastic and copper pipes can result in water wastage and reduced system efficiency. To address loose fittings, use a wrench to tighten the compression ring or threaded adapter securely. Regularly check the connections for any signs of loosening and re-tighten as needed to maintain a reliable joint.

Maintenance Tips

Regular Inspections

Performing routine inspections on plastic pipe and copper pipe connections is essential for identifying potential issues early on. Check for any visible leaks, corrosion, or unusual sounds that may indicate a problem. By addressing minor concerns promptly, you can prevent major plumbing issues in the future.

Proper Handling

Proper handling of plastic pipe and copper pipes is crucial to ensure their longevity and performance. Avoid excessive bending or twisting of the pipes during installation to prevent damage. When making connections, follow the recommended guidelines for each method to guarantee a secure and leak-free joint.

To ensure a successful connection between plastic and copper pipes, it is crucial to follow the outlined steps meticulously.

By recapitulating the key points discussed in this guide, individuals can confidently tackle similar projects with precision.

For future plumbing endeavors, considering the experiences of others who have faced pipe failures can serve as a valuable lesson.

Remember, proper installation techniques and attention to detail are paramount in maintaining a reliable and leak-free plumbing system.

See Also

Basic Guide: Soldering Copper Pipes for Novices

Quick Guide: Measuring Copper Pipes for DIY Projects

Simple Tutorial for Repairing a Split Copper Pipe

Becoming Proficient in Copper Pipe Fittings: An In-Depth Manual