How to Install Air Conditioning Copper Pipes Step-by-Step

To ensure the optimal performance of your air conditioning system, proper installation of air conditioning copper pipes is paramount. By understanding the importance of this process, you set the foundation for a comfortable indoor environment. This blog will provide you with a comprehensive overview of how to install these copper pipes step-by-step. Following a detailed guide offers numerous benefits, such as cost-efficiency and long-term functionality for your HVAC system. Read on to learn how to install air conditioning copper pipes effectively.

Tools and Materials Needed

When installing air conditioning copper pipes, having the right tools and materials is crucial for a successful outcome. Here are the essential tools and necessary materials you will need:

Essential Tools

Pipe cutter: A tool designed to cut copper pipes with precision.

Flaring tool: Essential for creating flares at the end of the pipes for secure connections.

Wrenches: Used to tighten and secure various components during the installation process.

Vacuum pump: Necessary for removing air and moisture from the system to prevent potential issues.

Necessary Materials

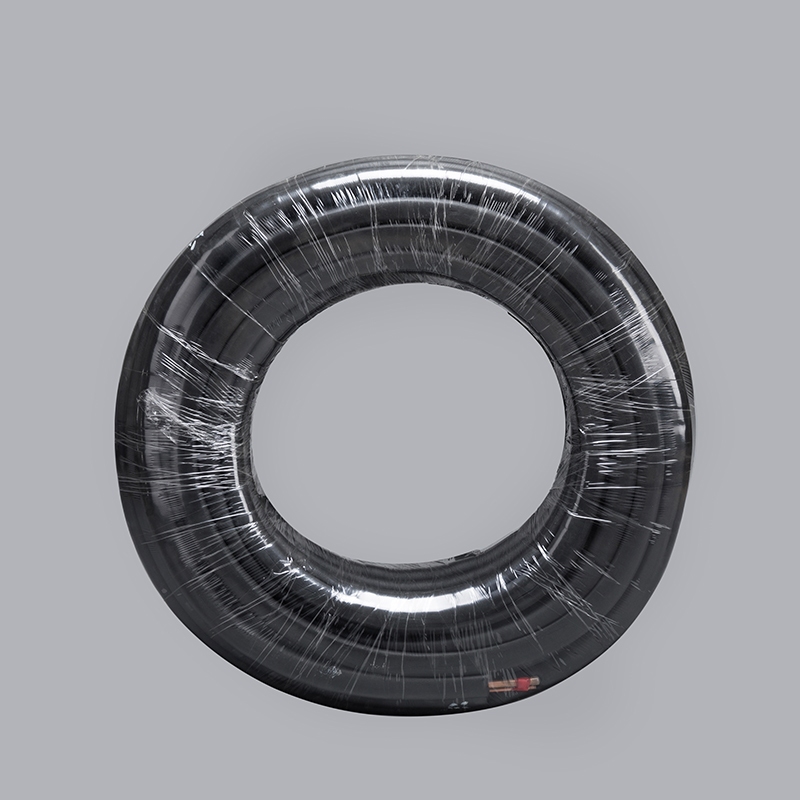

Copper pipes: The main component of the piping system, ensuring durability and efficient heat transfer.

Flare nuts: Used to securely connect different parts of the copper pipes together.

Insulation materials: Essential for preventing heat loss or gain in the system, maintaining efficiency.

Refrigerant: A vital substance that circulates through the copper pipes, facilitating heat exchange in the air conditioning system.

Preparing the Installation Site

Choosing the Location

When preparing for the installation of your air conditioning system, selecting the ideal location is crucial. Indoor unit placement should prioritize accessibility and proximity to the main area you wish to cool. For outdoor unit placement, ensure it is positioned in an open space with proper ventilation to maximize efficiency.

Clearing the Area

Before commencing the installation process, it is essential to clear the designated area effectively. Removing obstacles such as furniture or debris will create a safe environment for installation. Additionally, ensuring proper ventilation around both the indoor and outdoor units will contribute to optimal performance and longevity of your air conditioning system.

Measuring and Cutting the Pipes

To ensure precision in your installation process, measuring the required length of the copper pipes is essential. Begin by using a measuring tape to determine the exact dimensions needed for a seamless fit. Subsequently, proceed to mark the pipes accurately to indicate where they should be cut.

When it comes to cutting the pipes, employing a pipe cutter is crucial for achieving clean and precise cuts. This tool allows you to trim the copper pipes accurately without causing any damage or deformities. By ensuring clean cuts, you guarantee a smooth assembly process and optimal functionality of your air conditioning system.

Making Holes in the Wall

Marking the Drill Points

Measuring the distance

Measure the exact distance required for your installation project.

Use a measuring tape to determine the precise length needed for the copper pipes.

Ensure accuracy by double-checking your measurements before proceeding.

Marking with a pencil

Grab a pencil to mark the designated spots on the wall.

Make clear and visible marks to indicate where the holes should be drilled.

Precision is key, so take your time to ensure accurate markings for a seamless installation process.

Drilling the Holes

Choosing the right drill bit

Select a drill bit that matches the size of your copper pipes.

Opt for a high-quality drill bit to guarantee clean and precise holes in the wall.

The correct drill bit ensures a perfect fit for passing the pipes through without any complications.

Drilling at the correct angle

Position your drill at an optimal angle before starting.

Maintain a steady hand and apply consistent pressure while drilling into the wall.

By drilling at the correct angle, you ensure smooth passage for your copper pipes during installation.

Connecting the Pipes to the Indoor and Outdoor Units

Attaching the Pipes to the Indoor Unit

Aligning the pipes

Contractors emphasize aligning the copper pipes accurately with precision. This alignment ensures a seamless connection process between components, promoting efficient functionality of your air conditioning system.

Securing with flare nuts

The next crucial step involves securing the aligned pipes using flare nuts. By tightening these nuts securely by hand, you establish a robust connection that minimizes the risk of leaks or disconnections over time.

Attaching the Pipes to the Outdoor Unit

Aligning the pipes

Aligning the copper pipes with care is essential when connecting them to the outdoor unit. Proper alignment guarantees smooth airflow and optimal performance, contributing to the overall efficiency of your air conditioning system.

Securing with flare nuts

Securing the pipes to the outdoor unit involves utilizing flare nuts for a secure fit. By tightening these nuts diligently, you ensure a stable connection that withstands external factors and environmental conditions for long-lasting performance.

Securing the Pipes

Using Flare Nuts

Tightening the nuts

To ensure a reliable connection, firmly grip the flare nut and rotate it clockwise until snug. This action guarantees a secure attachment of the pipes, preventing potential leaks or disconnections.

Ensuring a secure fit

Maintaining a tight seal is essential for optimal system performance. By confirming that the flare nut is securely fastened, you establish a durable connection that withstands external factors and environmental conditions.

Insulating the Pipes

Applying insulation materials

Shielding your copper pipes with insulation materials is crucial for energy efficiency. By wrapping the pipes with insulating material, you prevent heat loss or gain, promoting cost-effective operation and reducing energy consumption.

Securing insulation with tape

After applying the insulation materials, use tape to secure them in place. This step ensures that the insulation remains intact and provides consistent coverage along the length of the pipes, maximizing thermal efficiency.

Testimonials:

Unknown

Absolutely. By maintaining the intended temperature of the refrigerant,

insulation significantly reduces energy consumption. Find out how in our article on Insulation Thickness Calculator.

Testing the System for Leaks

Using a Vacuum Pump

Connecting the pump

Attach the vacuum pump to the system, ensuring a secure connection.

Activate the pump to initiate the vacuum process within the air conditioning copper pipes.

Creating a vacuum

Allow the vacuum pump to run for a sufficient duration to remove any air or moisture present in the system.

Verify that a complete vacuum is achieved before proceeding with further installation steps.

Checking for Leaks

Using a leak detector

Employ a reliable leak detector tool to inspect all connections along the copper pipes.

Methodically scan each joint and connection point for any signs of leakage or potential issues.

Inspecting all connections

Carefully examine every connection point visually to ensure there are no visible leaks or gaps.

Confirm that each component is securely fastened and aligned correctly for optimal performance and longevity of your air conditioning system.

To achieve a successful installation of your air conditioning system, it is vital to follow manufacturer's instructions meticulously. This practice ensures precision and minimizes errors throughout the process.

Maintaining the correct distance between units is paramount for optimal efficiency. By adhering to this guideline, you guarantee seamless operation and longevity of your HVAC system.

Embrace the journey of installation with care and attention to detail. Following each step carefully paves the way for a flawless outcome, providing you with a reliable and efficient air conditioning setup.

See Also

Effortless Guide: Installing Copper Tubes for Air Conditioning

Benefits of Selecting Copper Tubing for AC Systems

Comprehensive DIY Manual for Repairing Copper Tube Holes in AC

The Impact of Pure Copper Tubing on Air Conditioning Innovation

Revealing the Wonders: Pure Copper Tubing's Role in AC Advancement