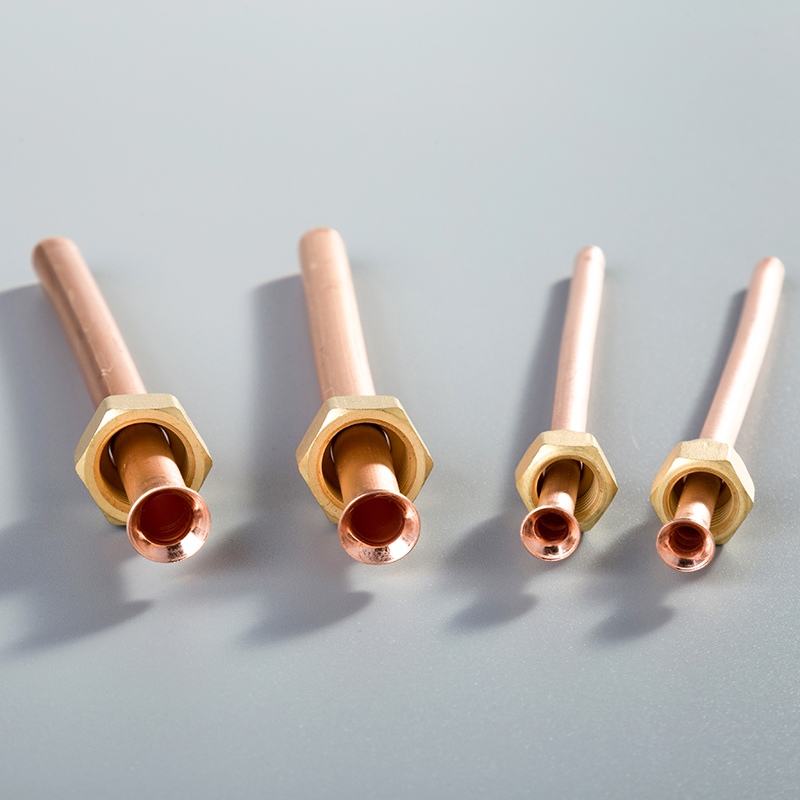

How to Measure the Outside Diameter of 3/4 Inch Copper Pipe

Measuring the 3/4 copper pipe od of copper pipes, such as a 3/4 inch copper pipe, is crucial for various applications. Understanding the process and significance of accurate measurements ensures proper fit and safety in projects. Achieving precise measurements like the 0.875 inches OD of a 3/4 pipe copper is essential to avoid leaks and comply with industry standards. By mastering the measurement techniques, individuals can confidently identify and work with different copper pipe sizes effectively. Additionally, knowing the dimensions of a 3/8 copper pipe can be equally important. So, are copper pipes safe for your projects? Absolutely, when measured and installed correctly, they provide reliable and durable solutions.

Tools Needed

Measuring Tools

To accurately measure the outside diameter of a 3/4 inch copper pipe, individuals require specific tools. Calipers are essential for precise measurements, allowing users to determine the exact diameter with accuracy. These tools come in various types, such as slide calipers, which provide electronic readouts for ease of measurement. Additionally, tape measures play a crucial role in measuring long distances and comparing dimensions to standards. They are available in steel or tape rule varieties to suit different measurement needs.

Safety Equipment

When working with copper pipes, safety should always be a top priority. Utilizing gloves is vital to protect hands from sharp edges or potential injuries during the measurement process. Furthermore, wearing safety goggles ensures eye protection from any debris or particles that may arise while handling the pipes. Prioritizing safety equipment not only safeguards individuals but also promotes a secure working environment for all involved in the project.

By incorporating these measuring tools and safety equipment into the process of measuring a 3/4 inch copper pipe, individuals can enhance accuracy and efficiency while maintaining a safe work environment.

Measurement Process

Preparing the Pipe

To begin the measurement process of a 3/4 inch copper pipe, start by cleaning the pipe thoroughly. Removing any dirt or debris ensures accurate measurements and prevents interference with the measuring tools. Once the pipe is clean, proceed by positioning the pipe securely in place for precise measurements. Proper positioning eliminates potential errors and guarantees reliable results when determining the outside diameter.

Using a Caliper

When measuring the 3/4 copper pipe od, utilizing a caliper is essential for obtaining accurate readings. Begin by setting the caliper to match the diameter of the copper pipe. This step ensures that the caliper provides precise measurements without any discrepancies. With the caliper properly set, proceed to measure the diameter of the pipe carefully. Take multiple measurements to confirm consistency and accuracy in determining the exact outside diameter of the 3/4 inch copper pipe.

Using a Tape Measure

Alternatively, measuring a 3/4 inch copper pipe can also be achieved using a tape measure effectively. Start by wrapping the tape measure around the circumference of the pipe gently. Ensure that there are no twists or bends in the tape for an accurate measurement. Once wrapped, carefully read the measurement displayed on the tape measure. By interpreting this measurement correctly, individuals can determine whether it aligns with standard sizes and specifications accurately.

By following these steps meticulously, individuals can successfully measure and identify a 3/4 inch copper pipe's outside diameter with precision and confidence.

Importance of Accurate Measurement

To ensure a proper fit when working with copper pipes, accuracy in measurements is paramount. By avoiding leaks through precise measurements, individuals guarantee the safety of their projects. Maintaining compliance with building codes and industry standards is crucial to uphold the integrity of installations.

Ensuring Proper Fit

Avoiding Leaks

Leakage in plumbing systems can lead to water damage and mold growth, posing health risks and structural issues. By accurately measuring copper pipe diameters, individuals prevent leaks that could compromise the efficiency and longevity of their projects.

Ensuring Safety

Safety should always be a priority in any construction endeavor. Accurate measurements contribute to secure installations, reducing the risk of accidents or malfunctions. When copper pipes are safe due to precise measurements, individuals can work confidently knowing they have prioritized safety.

Compliance with Standards

Building Codes

Adhering to building codes is essential for legal compliance and structural integrity. Properly measured copper pipes ensure that constructions meet the required standards, preventing potential hazards and ensuring durability over time.

Industry Standards

In addition to local regulations, following industry standards guarantees high-quality outcomes. By measuring copper pipe dimensions accurately, professionals align their work with established norms, fostering reliability and consistency in the field.

Understanding the challenges and importance of accurate pipe measurements in the oil and gas industry is crucial for project success.

Precision in pipe fitting is vital for safety, efficiency, and environmental protection.

Importance of proactive pipe end measurement leads to better fits, stronger welds, and safer pipelines.

See Also

Simple Steps: How to Determine Copper Pipe Dimensions

Quick Guide: How to Gauge Copper Pipe for DIY Wins

Effortless Steps: How to Size Copper Pipe Professionally