How to Measure Copper Pipe Diameter: A Step-by-Step Guide

Accurately measuring copper pipe diameter is a crucial step in ensuring successful copper pipe plumbing projects. The process involves understanding the significance of precise measurements to prevent structural weaknesses and failures in piping systems. Copper pipe fittings for plumbing are measured differently, with Outside Diameter (OD) and Nominal Pipe Size (NPS) being key considerations. In DIY projects, precision is paramount, and accurate measurements are fundamental for success. Guessing the wrong size can lead to unnecessary expenses and frustrating experiences. Therefore, mastering the art of measuring copper pipes effectively is essential for seamless fittings and eliminating costly errors, including copper pipe leak repair.

Tools Needed

Basic Tools

Steel Measuring Tape: Consider using a steel measuring tape for added precision and durability in measuring copper pipes for DIY projects.

String or Flexible Tape: Begin by wrapping the string or flexible tape around the copper pipe to determine its circumference accurately.

Measuring Tape or Ruler: Use a measuring tape or ruler to measure the length of the string wrapped around the pipe, ensuring precise measurements.

Advanced Tools

Pipe Measuring Tool: A handy dandy pipe measuring tool is available for quickly and easily measuring the size of pipes.

Caliper: For precise measurements of copper piping, utilizing calipers can be highly effective. Position the calipers perpendicular to the pipe's surface for accurate readings.

Pipe Sizing Tool: This tool provides a quick and efficient way to measure the diameter of copper pipes accurately.

By having these tools at your disposal, you can ensure that your measurements are precise and reliable, leading to successful outcomes in your plumbing projects. Remember, accuracy is key when working with copper pipes to avoid any unnecessary errors or setbacks during installations or repairs.

Measuring Techniques

When measuring copper pipe diameter, precision is key to ensuring successful plumbing projects. Utilizing different techniques can help achieve accurate results and prevent errors in fittings.

Using String or Flexible Tape

Wrapping the Pipe

Start by wrapping the string or flexible tape around the copper pipe snugly, ensuring no gaps or overlaps.

Measuring the String Length

Measure the length of the string precisely, making sure it follows the entire circumference of the pipe.

Calculating the Diameter

Divide the measured length by pi (approximately 3.1415) to determine the copper pipe diameter accurately.

Using Measuring Tape or Ruler

Direct Measurement

Place the measuring tape or ruler across the end of the pipe to measure its diameter directly.

Ensuring Accuracy

Double-check your measurements to ensure accuracy and avoid any discrepancies in sizing.

Using Caliper

Measuring Outer Diameter

Position the caliper perpendicular to the pipe's surface and measure its outer diameter carefully.

Ensuring Precision

Verify your measurements for precision, especially when dealing with smaller sizes of copper pipes.

Identifying Pipe Markings

Reading Labels

To identify the size of a copper pipe accurately, reading labels is essential. Look for markings on the pipe that indicate its dimensions and type. These labels often provide information about the diameter and material of the pipe, aiding in proper fittings and installations. Pay close attention to any numbers or letters stamped on the surface, as they can reveal crucial details about the pipe's specifications. By interpreting these labels correctly, you can ensure that you select the right fittings and connectors for your plumbing projects.

Understanding Markings

Understanding markings on copper pipes is key to determining their size and type. Different manufacturers may use specific codes or symbols to represent various dimensions and characteristics of the pipes. Take note of any engravings or embossed information on the surface of the pipe, as they serve as valuable indicators of its properties. By familiarizing yourself with these markings, you can confidently choose compatible components for your plumbing system without confusion or errors.

Tips and Considerations

Common Mistakes

Incorrect Measurements

When taking measurements of copper pipes, one common mistake is inaccuracies in the recorded dimensions. To avoid this error, ensure that the measuring tools are aligned correctly and that the readings are precise. By double-checking the measurements before proceeding with any fittings or installations, you can prevent potential issues arising from incorrect calculations.

Misreading Markings

Misinterpreting the labels or markings on copper pipes can lead to selecting incompatible fittings or connectors for your plumbing projects. It is crucial to carefully examine these indicators to determine the size and type of the pipe accurately. By understanding the significance of each marking, you can confidently proceed with your DIY tasks without encountering setbacks due to misread information.

Ensuring Accuracy

Double-Checking Measurements

To guarantee accurate results when measuring copper pipe diameter, always verify your initial measurements by rechecking them using different tools or techniques. This practice helps eliminate errors and ensures that the recorded dimensions align consistently across various methods. By cross-referencing your measurements, you can enhance the precision of your calculations and minimize the risk of inaccuracies in your plumbing projects.

Using Multiple Tools

Employing a combination of measurement tools enhances the reliability of your results when determining copper pipe sizes. By utilizing various instruments such as calipers, measuring tapes, and rulers simultaneously, you can validate the accuracy of your measurements through comparison. This approach not only reinforces the precision of your calculations but also provides a comprehensive assessment of the pipe dimensions for improved confidence in your plumbing endeavors.

Applications

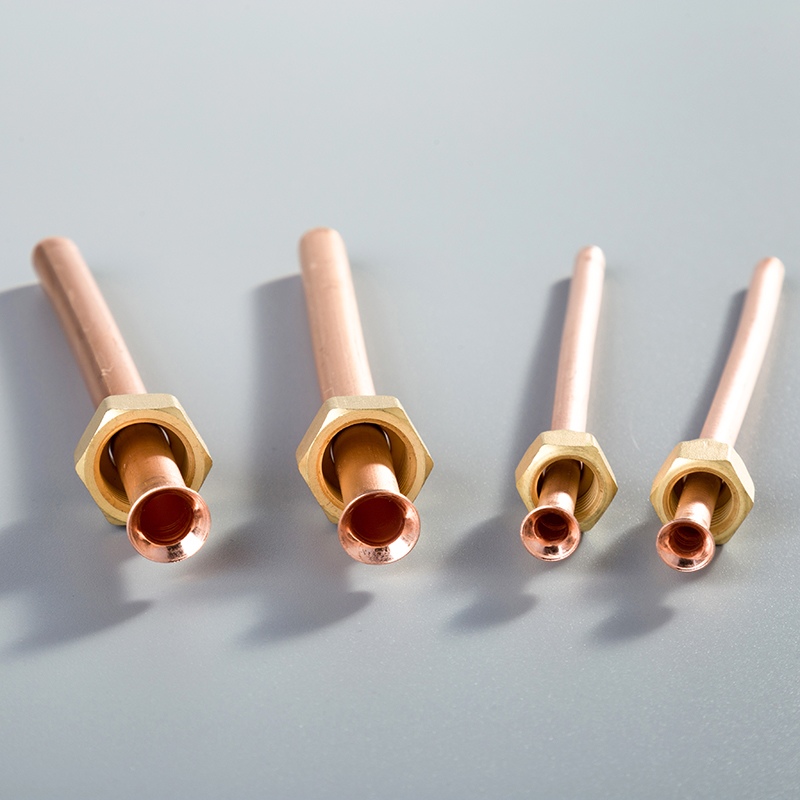

Copper Pipe Fittings for Plumbing

Copper pipe fittings for plumbing play a vital role in establishing secure connections within piping systems. The accurate measurement of copper pipes ensures compatibility with corresponding fittings, promoting efficient water flow and preventing leaks. By selecting appropriate fittings based on precise measurements, you can optimize the performance and longevity of your plumbing installations while minimizing maintenance requirements.

Copper Pipe Leak Repair

In scenarios where copper pipe leak repair is necessary, precise measurements are essential for identifying damaged sections that require replacement or sealing. Accurately measuring the affected areas enables you to procure suitable repair materials and implement effective solutions promptly. By addressing leaks with precision and utilizing proper techniques based on accurate measurements, you can restore functionality to your plumbing system efficiently.

Robert Robillard emphasizes the critical role of measuring instruments in ensuring precision and confidence during DIY tasks. A reliable tape measure, steel ruler, and other tools empower enthusiasts to tackle projects accurately. Investing in top layout tools guarantees craftsmanship marked by precision. Remember, meticulous measurements are the foundation of a well-executed project.

Baoyuan highlights the importance of accurate measurements in plumbing projects. Precision is key when understanding how to measure copper pipe diameter. Accurate measurements ensure seamless fittings and prevent costly errors. Mastering these fundamentals can elevate your plumbing skills to a professional level.

Mastering the art of measuring copper pipes effectively is crucial for successful DIY projects. Precision ensures seamless fittings and eliminates costly errors. Understanding the significance of precise dimensions and following correct steps can elevate your craftsmanship to professional levels. With the right guidance, you can set a solid foundation for your DIY endeavors.

See Also

Mastering Copper Pipe Sizing: A Comprehensive Tutorial

Simple Steps: Mastering Copper Pipe Measurement

Quick Tutorial: Measuring Copper Pipe for DIY Projects