How to Use a Crimping Tool for Copper Pipes

Crimping tool for copper pipe plays a vital role in plumbing, ensuring secure and leak-free connections for copper pipes. The process involves applying pressure to fittings using a crimping tool for copper pipe, creating durable seals. By utilizing this method, plumbers can achieve efficient and reliable results in their installations. The benefits of using a crimping tool for copper pipe include quick and permanent connections, essential for maintaining the integrity of plumbing systems. Embracing this technique not only saves time but also guarantees long-lasting performance for cut copper pipe installations. Additionally, when cutting copper pipe, it is crucial to ensure precise measurements for a perfect fit. While solder for copper pipe is another method, the crimping tool offers a faster and more reliable alternative.

Tools and Materials

Required Tools

To ensure a successful copper pipe installation, Crimping tool for copper pipe is essential. This tool applies pressure to fittings, creating secure connections. Alongside the crimping tool, a Pipe cutter is necessary to achieve precise cuts on the copper pipes. Additionally, having a Measuring tape ensures accurate measurements for fitting alignment.

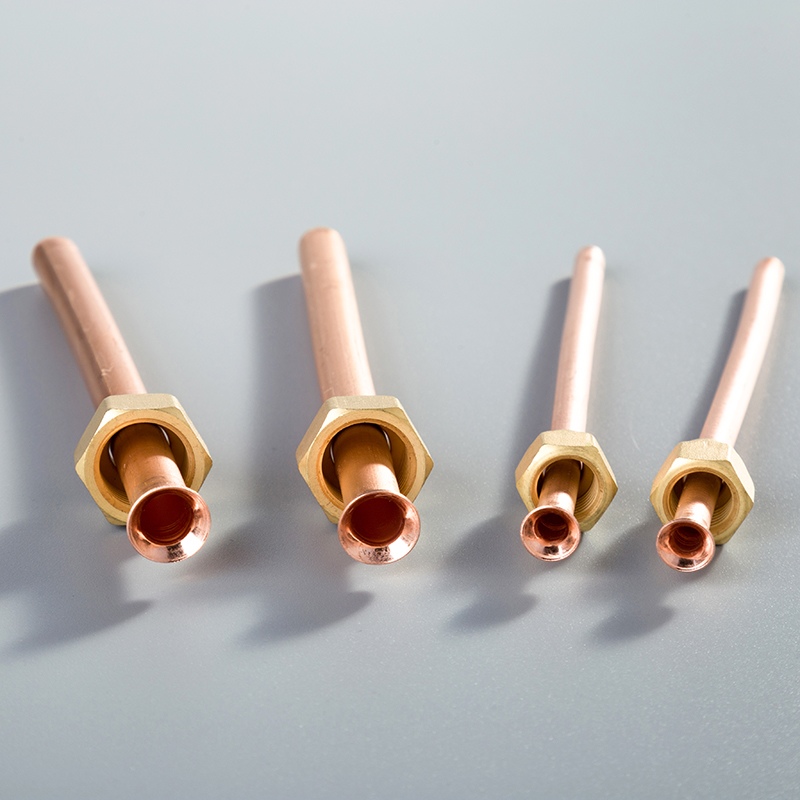

Necessary Materials

For a seamless plumbing experience, gather high-quality materials such as Copper pipes. These pipes are durable and resistant to corrosion, ensuring long-lasting performance. Crimp fittings are crucial components that work in conjunction with the crimping tool to create watertight seals. Lastly, using a Marker helps in marking cut points accurately on the copper pipes for precise installations.

Power Crimping Tools offer quick and reliable connections due to technological advancements like automatic adjustment features. The growing demand for efficient plumbing solutions drives the need for these tools in the construction industry.

Powered Crimpers reduce physical strain and injury risks associated with manual crimping tasks by eliminating excessive grip force requirements.

Klauke EK50ML Cable Strip, Cut & Crimping Tool provides professional panel building kits containing battery-powered hydraulic tools for safe and quick crimping without insert changes.

Mechanical PEX Pipe Crimping Tools are versatile tools used for various types of pipes and sleeves, including aluminum-plastic and PEX pipes, enhancing flexibility in plumbing applications.

Preparing the Pipe

Measuring the Pipe

When measuring the pipe, accuracy is key to a successful installation. Using a measuring tape ensures precise dimensions for the copper pipes, guaranteeing a snug fit with other components. By aligning the tape along the pipe's length, plumbers can determine the exact size required for optimal performance. Marking the cut point on the pipe is crucial before proceeding with any alterations. This step helps in identifying where to make precise cuts, ensuring that each section fits seamlessly into the plumbing system.

Cutting the Pipe

To achieve clean and accurate cuts, using a pipe cutter is essential. This tool allows plumbers to create smooth edges on copper pipes, preventing any obstructions or leaks in the system. By rotating the cutter around the pipe, professionals can maintain control over the cutting process, resulting in precise lengths for each section. Ensuring a clean cut is vital to guarantee proper connections and prevent any potential leaks that may arise from uneven edges.

Fitting Preparation

Before assembling components, it's crucial to prepare both ends of the pipes adequately. Cleaning the pipe ends removes any debris or contaminants that could affect the connection quality. By using appropriate cleaning tools, plumbers can ensure that each surface is free from impurities, promoting secure fittings. Additionally, checking the fitting size before installation prevents any mismatch issues during assembly. Verifying that fittings align correctly with pipe dimensions avoids complications and guarantees a seamless integration within the plumbing system.

Crimping the Pipe

Setting Up the Crimping Tool

Installing the correct jaw

To begin the crimping process effectively, plumbers must install the appropriate jaw on the crimping tool. This step ensures that the tool is ready to create secure connections between copper pipes and fittings without any complications. By selecting the correct jaw size based on the fitting dimensions, professionals can guarantee a precise and tight seal for optimal plumbing performance.

Securing the crimping tool

Once the jaw is in place, it is essential to secure the crimping tool before proceeding with the next steps. By ensuring that the tool is stable and firmly positioned, plumbers can maintain control over the crimping process. This stability minimizes any potential errors during operation, allowing for consistent and reliable results in creating watertight seals.

Positioning the Tool

Aligning with the fitting

Proper alignment of the crimping tool with the fitting is crucial for successful plumbing installations. Plumbers should align the tool precisely with the designated spot on the fitting to apply pressure accurately. This alignment ensures that the crimp is uniform and secure, preventing any leaks or disruptions in the plumbing system's functionality.

Ensuring perpendicular placement

Maintaining a perpendicular position of the crimping tool during operation is key to achieving professional results. By keeping the tool at a right angle to both the pipe and fitting, plumbers can ensure that pressure is evenly distributed across all sides of the connection. This perpendicular placement guarantees a consistent and reliable crimp, essential for long-lasting and leak-free plumbing systems.

Making The Crimp

Squeezing The Handle

With everything properly aligned and secured, it's time to squeeze the handle of the crimping tool. Applying controlled pressure through the handle initiates the crimping process, deforming the fitting onto the copper pipe securely. Plumbers should exert steady force while squeezing the handle to ensure a tight seal without damaging any components.

Checking The Crimp

After completing the crimp, it's essential to inspect the connection thoroughly. Plumbers should visually examine the crimped area to verify that it meets quality standards and forms a watertight seal around the pipe. Any irregularities or imperfections should be addressed promptly to prevent potential leaks or issues in the plumbing system's performance.

Recap of the Steps:

The process of using a crimping tool for copper pipes involves precise measurements, clean cuts, and secure fittings.

Proper setup and alignment of the crimping tool are essential for successful crimps on copper pipes.

Squeezing the handle initiates the crimping process, ensuring watertight seals for plumbing installations.

Benefits of Using a Crimping Tool:

Testimonials from selected Klauke testers highlight the efficiency and reliability of tools like the EKWF120ML crimping tool in creating durable connections.

Quick and permanent connections provided by power crimping tools ensure long-lasting performance in plumbing systems.

Utilizing a mechanical PEX pipe crimping tool enhances flexibility in various plumbing applications, meeting industry demands efficiently.

Encouragement to Follow the Guide:

Plumbers are encouraged to embrace the guide's techniques for successful plumbing installations. By utilizing crimping tools, professionals can achieve efficient results while maintaining the integrity of their work. Remember, precision and attention to detail are key in creating leak-free connections that stand the test of time.

See Also

Selecting the Top Flaring Tool for 1/2 Copper Pipes

5 Simple Ways to Connect Fittings on Curved Copper Pipes

Key Advice for Utilizing 1/4 Copper Pipe Fittings