Understanding Copper Pipe Types for HVAC Applications

Copper pipes are very important in HVAC systems, and finding a reliable HVAC copper pipe supplier is essential.

They are strong and work well for a long time, making them a preferred choice.

Copper moves heat better than aluminum, about eight times faster, which is a significant advantage.

This efficiency makes it great for carrying refrigerants under high pressure and heat.

Copper pipes can handle up to 1000 PSI and extreme temperatures, ensuring durability.

They work effectively in both hot and cold weather, preventing pipes from freezing in winter.

Over 70% of HVAC systems worldwide utilize copper pipes, highlighting their importance.

As cities grow, especially in the Asia-Pacific region, the demand for copper pipes from HVAC copper pipe suppliers continues to increase.

Choosing a reputable copper pipe supplier ensures you receive strong, long-lasting materials for your HVAC needs.

Key Takeaways

Copper pipes are important for HVAC systems because they are strong and transfer heat well.

Type K pipes work best for high-pressure jobs.

Type L pipes are strong but also flexible, good for homes.

Type M pipes are cheaper and work for low-pressure systems.

DWV pipes are made for waste and vents, not for pressure.

Picking the right copper pipe for pressure and conditions helps HVAC systems last longer and work better.

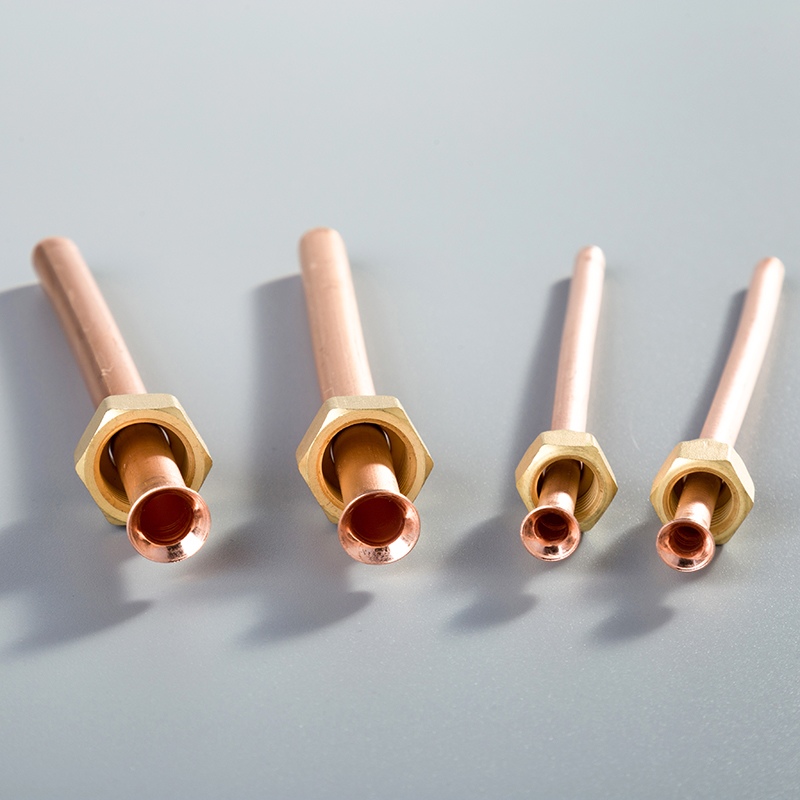

Types of Copper Pipes for HVAC Systems

Type K Copper Pipes

Type K copper pipes are the strongest and toughest type. They are used in HVAC systems with high pressure and tough conditions. Their thick walls make them great for underground use and long-lasting.

Here are some main features of Type K copper pipes:

Very strong and reliable in hard conditions.

Resist rust well, so they last longer.

Strong joints that keep the system working properly.

Move heat well, making HVAC systems work better.

Easy to bend when softened, helping with installation.

Can be fixed or changed on-site, saving time.

Check the table below for more details:

Specification Type | Details |

|---|---|

Dimensions | Size rules for Type K copper pipes in HVAC systems. |

Tolerances | Quality checks to ensure good performance. |

Mechanical Properties | Info about strength, rust resistance, and durability. |

Cleanliness | Clean standards for HVAC system use. |

If you need a pipe for high pressure and tough jobs, Type K is the best choice.

Type L Copper Pipes

Type L copper pipes are strong but also flexible, making them useful. These pipes are thinner than Type K but still last a long time. They are often used in homes and businesses for HVAC systems.

Here are some benefits of Type L copper pipes:

Feature | Type L Copper Pipes |

|---|---|

Strength and Flexibility | Strong but easy to install. |

Versatile Applications | Works for plumbing and HVAC systems. |

Cost-Effectiveness | A good mix of price and quality. |

Pressure Resistance | Handles medium pressure, not as strong as Type K. |

Use in Extreme Conditions | Not ideal for very tough environments. |

Best Use Cases | Great for business HVAC and fire safety systems. |

Type L pipes are a budget-friendly choice for HVAC systems that don’t need the extra strength of Type K. Their flexibility makes them a favorite for many uses.

Type M Copper Pipes

Type M copper pipes are the lightest and cheapest option. They have thinner walls, so they are not as strong as Type K or Type L. Still, they work well for low-pressure HVAC systems, especially in homes.

The thin walls of Type M pipes make them easy to cut and install, saving time. They are not good for high-pressure or tough conditions but are a smart choice for simple systems.

If you’re working on a home HVAC project with a tight budget, Type M pipes might be the best option.

DWV Copper Pipes

DWV copper pipes are made for Drain, Waste, and Vent systems. They are not used for pressurized fluids, so they don’t work for refrigerants in HVAC systems. Instead, they help remove waste and vent gases, keeping your HVAC system running smoothly.

Key Features of DWV Copper Pipes

DWV pipes have special traits that make them different from other types:

Thin Walls: These pipes are thinner than Type K, Type L, and Type M pipes. This makes them light and easy to carry.

Non-Pressurized Applications: DWV pipes are made for systems that don’t need to handle pressure.

Corrosion Resistance: Copper resists rust, so these pipes last longer in waste systems.

Ease of Installation: Their light weight makes them simple to install, saving time and effort.

Tip: Use DWV pipes for waste removal and venting in HVAC systems. Don’t use them for refrigerants or pressurized systems.

DWV Copper Pipes vs. Other Copper Pipe Types

Knowing how DWV pipes differ from others helps you choose wisely:

Pipe Type | Wall Thickness | Pressure Resistance | Best Use Case |

|---|---|---|---|

Type K | Thick | High | Underground and tough conditions |

Type L | Medium | Moderate | Residential and commercial HVAC |

Type M | Thin | Low | Budget-friendly home HVAC |

DWV | Thinnest | None | Waste and vent systems |

DWV pipes are not the same as Type M pipes or others. They are made for specific jobs in HVAC systems, like waste removal, not refrigerant transport.

When to Choose DWV Copper Pipes

Pick DWV pipes when your HVAC system needs waste removal and gas venting. These pipes are perfect for non-pressurized jobs, like drainage systems. Their light design makes them easy to install, even in small spaces.

Note: If your HVAC system uses refrigerants or high-pressure fluids, choose Type M pipes or stronger options.

Characteristics and Advantages of Copper Pipe Types

Durability and Pressure Resistance

Copper pipes are very strong and handle high pressure well. Type K pipes have thick walls, making them great for tough jobs like underground use. Tests show they can handle much more pressure than expected, making them reliable for HVAC systems. They also pass fatigue tests, lasting over 250,000 cycles without breaking.

Type L pipes are also durable and work well for homes and businesses. They are not as strong as Type K, but their medium-thick walls handle most pressures. Special ASTM B280 copper resists rust, so they last longer, even in wet places.

Tip: Use Type K pipes for high-pressure systems. For medium pressure, choose Type L pipes.

Thermal Efficiency and Flexibility

Copper pipes are great at moving heat, which is key for HVAC systems. Type L pipes are flexible and work well for heating and cooling. Their flexibility makes them easy to install in tight spots. Type K pipes are less bendable but transfer heat better, making them perfect for tough conditions.

Smaller copper pipes save energy by moving heat faster and needing less refrigerant. This is helpful for air-conditioning and cooling systems. Type M pipes are lightweight and easy to use but are best for low-pressure systems.

Note: If you need flexible pipes for small spaces, pick Type L pipes.

Cost and Application Suitability

Copper pipes differ in price and use. Type K pipes are the strongest and cost the most. They are worth it for hard jobs. Type L pipes balance cost and strength, making them popular for homes and businesses.

Type M pipes are the cheapest and good for simple home HVAC projects. Their thin walls lower costs but can’t handle high pressure. Smaller copper pipes also save money by using less refrigerant and fitting into compact designs.

New copper alloys improve performance and lower costs, making copper pipes a smart choice for modern HVAC systems.

Tip: Think about your system’s pressure needs and budget. Type L pipes are often the best value for most HVAC systems.

HVAC Applications for Copper Pipe Types

Residential HVAC Systems

Copper pipes are important for home HVAC systems. Semi-flexible copper pipes move refrigerants and include a liquid line and suction line. Their size changes based on the brand and distance between parts. These pipes are easy to install because they bend well, even in small spaces. They last a long time and can be recycled, which helps the environment.

Many homeowners choose Type L copper pipes because they are strong and affordable. These pipes work well for medium pressure, making them great for most home HVAC systems. For cheaper projects, Type M pipes are lightweight and cost less. However, they are better for systems with low pressure.

Tip: Pick copper pipes based on your system's pressure needs and the space between parts.

Commercial HVAC Systems

Commercial HVAC systems need strong and reliable materials. Copper pipes are perfect because they move heat well, resist rust, and last a long time. As renewable energy and manufacturing grow, copper pipes are used more in commercial HVAC systems.

Some trends in commercial HVAC include:

Demand stays steady despite changing raw material prices and competition.

New technologies and government rules focus on saving energy.

Copper pipes are popular because they recycle easily and work well.

Type K copper pipes are best for high-pressure systems in businesses. For less tough jobs, Type L pipes are cheaper but still strong.

Specialized HVAC Applications

Special HVAC systems, like those in factories or extreme places, need careful planning. Copper pipes are great here because they handle heat changes without breaking. Special setups, like offsets, 'U' bends, or coil loops, help stop damage from expanding or shrinking pipes.

Asia-Pacific uses copper pipes the most for special HVAC systems due to big investments. North America also uses them a lot because of high HVAC sales. These trends show that copper pipes are trusted worldwide for tough jobs.

Note: For special systems, plan for pipe movement to avoid bending or breaking. Use expansion joints or special shapes to keep the system safe.

Choosing the Right Copper Pipe for Your HVAC System

Factors to Consider (Pressure, Durability, Environment)

Picking the right copper pipe means thinking about important factors. First, check your system's pressure needs. High-pressure systems, like those in factories, need strong pipes such as Type K or Type L. For home systems with low pressure, Type M pipes are cheaper and work well.

Durability is also important. Copper pipes resist rust, but their strength depends on the type. Type K pipes last the longest because of their thick walls, making them good for underground use. Type L pipes are strong and flexible, perfect for homes and businesses. Type M pipes are less strong but fine for easy jobs in safe places.

Think about the environment too. If your system faces extreme heat or tough conditions, choose pipes that can handle it. For example, soft Type L pipes are great for heating systems, while Type K pipes work well underground.

Tip: Match the pipe type to your system’s needs for better performance.

Comparing Copper Pipe Types for HVAC Needs

Knowing the pros and cons of each pipe type helps you decide. Here's a simple comparison:

Type K: Best for high pressure and hard conditions. Thick walls make it very strong.

Type L: Good for homes and businesses. It balances strength, flexibility, and cost.

Type M: Great for cheap home projects. Thin walls make it light but not for high pressure.

DWV: Made for waste systems. Not for refrigerants or pressurized fluids.

Copper pipes also move heat well, helping HVAC systems cool faster. Special grooved copper tubes improve heat transfer and save money. These tubes work with different refrigerants and reduce costs, making them a smart choice for modern systems.

Note: For cooling systems, Type L or ACR pipes are best for refrigerants.

Practical Tips for Selection and Installation

Choosing the right pipe is just the start; installing it correctly matters too. Follow these tips:

Know Your System’s Needs: Check the pressure, temperature, and environment your system will face. This helps pick the right pipe.

Choose a Reliable Supplier: Work with a trusted hvac copper pipe supplier for quality pipes that meet standards.

Plan for Pipe Movement: Copper pipes expand and shrink with heat. Use special joints or shapes to stop damage.

Install Pipes Properly: Clean pipes before use. Use the right tools to make strong connections.

Ask Experts for Help: If unsure, get advice from HVAC professionals.

Customer Name | Feedback |

|---|---|

S. Wagner | Happy with quick service and skilled technicians. |

T. Walsh-Davis | Liked the value and professional work provided. |

L. Meinke | Praised the team for fixing heating problems carefully. |

K. Edwards | Noted the technician’s care and skill during AC setup. |

M. Ware | Thanked the company for clear advice during an emergency. |

Callout: A trusted hvac copper pipe supplier gives quality pipes and helpful advice for choosing and installing them.

By thinking about these factors and following these tips, your HVAC system can work well and last a long time.

Copper pipes are important for HVAC systems. The four main types—Type K, Type L, Type M, and DWV—each have special uses. Picking the right one helps your system work well and last longer.

Type K: Best for tough jobs and high-pressure systems.

Type L: Works well for homes and businesses.

Type M: A cheaper choice for low-pressure systems.

DWV: Made for waste removal and venting, not for pressure.

Tip: Knowing these types helps you choose wisely for your HVAC system.

Choosing the right copper pipe improves efficiency, saves money, and makes your system last longer.

FAQ

What is the best copper pipe type for high-pressure HVAC systems?

Type K pipes are the strongest choice. Their thick walls handle high pressure. They work well underground or in tough industrial HVAC systems.

Can Type M copper pipes be used for commercial HVAC systems?

Type M pipes are not good for commercial systems. Their thin walls suit low-pressure home HVAC setups. For businesses, use Type L or Type K pipes instead.

Are DWV copper pipes used for refrigerants in HVAC systems?

DWV pipes are not made for refrigerants. They are used for waste and venting jobs. For refrigerants, pick Type L or Type K pipes.

How do copper pipes prevent freezing in winter?

Copper pipes stop freezing because they transfer heat well. This keeps HVAC systems working even in very cold weather.

What factors should you consider when selecting copper pipes for HVAC systems?

Think about pressure, strength, and the environment. Type K is best for high pressure. Type L is strong and flexible for homes and businesses.

See Also

The Complete Resource for Copper Pipe Varieties and Joining

Reasons to Opt for Copper Pipes in HVAC Systems

Transforming HVAC with 1/4 and 3/8 Copper Pipe Coils

Understanding Copper Pipe Dimensions: An In-Depth Overview

The Definitive Handbook for Installing Twin Copper Pipe Coils