Why Copper Pipes Are Crucial for Air Conditioning Units

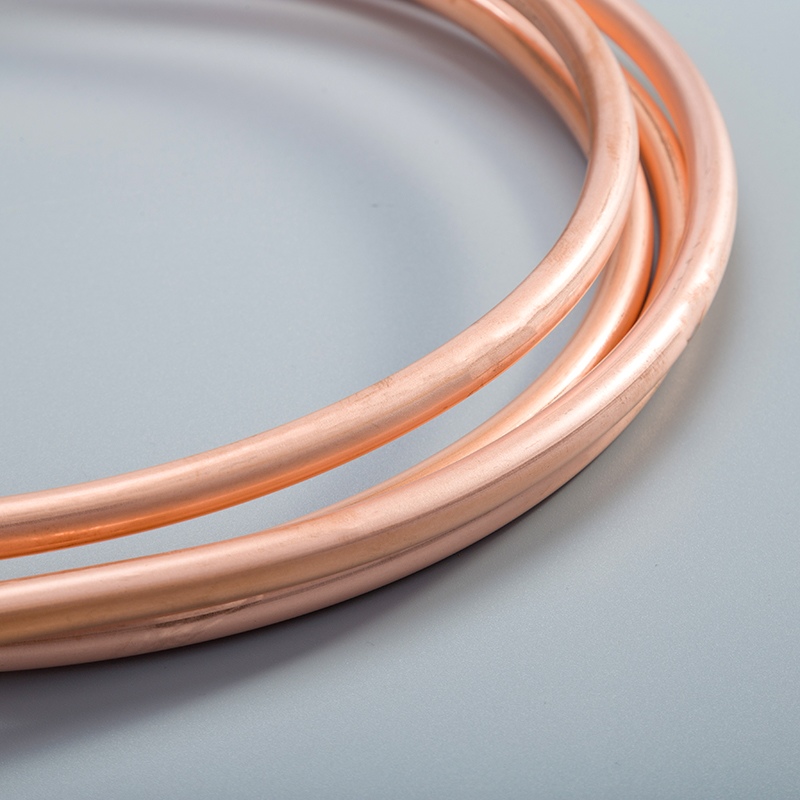

Copper pipes play a vital role in air conditioning units, offering unparalleled benefits that enhance the system's performance. Uncover the reasons why Pure Copper pipes are essential for Air Conditioning units through their exceptional durability, energy efficiency, and heat conductivity. These key attributes not only ensure longevity but also contribute to optimal cooling performance and improved energy conservation. This blog aims to shed light on the significance of copper pipes in air conditioning systems, highlighting their crucial role in maintaining efficiency and reliability.

Importance of Copper in Air Conditioning

Copper pipes are renowned for their durability and longevity, making them a top choice in air conditioning systems. With anti-corrosive properties that combat oxidation, copper ensures a prolonged lifespan for HVAC units. As an expert in Heating, Ventilation, and Air Conditioning Systems highlights, "Copper pipes are durable, work well with refrigerants, and don’t take a lot of material to be made." This underscores the efficiency and reliability that copper brings to air conditioning setups.

In terms of energy efficiency, copper's smooth inner surface minimizes friction within the pipes, leading to improved performance overall. This characteristic aligns with the insights from a Plumbing Industry Expert who emphasizes how copper remains a top choice for professionals across various industries like plumbing and HVAC. The expert notes, "For plumbing, HVAC, or even refrigeration systems, copper pipes remain a top choice."

When it comes to heat conductivity, copper excels at rapid heat absorption and effective heat transfer, crucial elements for optimal cooling performance in air conditioning units. The adaptability of copper to different installation needs further solidifies its position as the go-to material for HVAC systems.

As we delve deeper into the technical aspects of air conditioning units, it becomes evident that the role of copper is indispensable. Its unique properties not only enhance system performance but also contribute significantly to energy conservation and longevity.

Technical Advantages of Copper Pipes

High Thermal Conductivity

Copper pipes exhibit high thermal conductivity, a crucial feature that directly impacts the optimal cooling performance of air conditioning units. This exceptional property allows copper to efficiently absorb and distribute heat, ensuring that the system operates at peak efficiency. As highlighted in Residential Use of Copper Pipes in Air Conditioning, the seamless flow of refrigerants facilitated by copper tubing contributes significantly to the overall energy efficiency of HVAC systems.

Optimal Cooling Performance

The optimal cooling performance achieved through copper pipes is unparalleled in air conditioning technology. By effectively absorbing and transferring heat, copper ensures that the cooling process is efficient and reliable. According to Evolution of Copper Tubing in Air Conditioning, the durability and corrosion resistance of copper play a vital role in maintaining consistent cooling performance over extended periods, making it an indispensable material for HVAC applications.

Efficient Heat Distribution

Efficient heat distribution is a hallmark of copper pipes in air conditioning systems. The structural integrity and malleability of copper tubing allow for seamless heat transfer throughout the unit, optimizing energy consumption and enhancing overall performance. As outlined in Copper's Role in HVAC Systems, the compatibility of copper with diverse environments underscores its ability to facilitate efficient heat exchange, further emphasizing its importance in maintaining ideal operating conditions.

Structural Integrity

The structural integrity of copper pipes sets them apart as a preferred choice for air conditioning installations. With inherent strength and flexibility, copper tubing offers durability and ease of maintenance, ensuring long-term reliability for HVAC systems. As detailed in Air-Conditioning Copper Pipe Market Overview, the malleability of copper enables seamless installation processes, reducing downtime and enhancing operational efficiency.

Strength and Flexibility

The strength and flexibility exhibited by copper pipes are essential characteristics that contribute to their widespread use in air conditioning units. These properties not only ensure longevity but also simplify maintenance procedures, reducing overall costs associated with system upkeep. By prioritizing structural integrity, manufacturers can guarantee optimal performance levels while minimizing potential disruptions due to maintenance requirements.

Ease of Installation

The ease of installation provided by copper tubing streamlines the setup process for air conditioning systems, offering professionals a reliable solution for efficient installations. The adaptability and workability of copper make it a versatile material that aligns with industry standards across various applications like plumbing and refrigeration systems. Through its ease of installation, copper remains a top choice for professionals seeking durable solutions for complex HVAC requirements.

Compatibility with Refrigerants

Copper's compatibility with refrigerants is a critical aspect that enhances its functionality within air conditioning setups. The design of refrigerant lines using copper tubing ensures optimal performance by facilitating the seamless flow of cool gas throughout the system. As emphasized in Copper Pipes for Energy-Efficient Air Conditioning, this compatibility minimizes energy loss within the unit, contributing to enhanced energy efficiency and sustainable operation.

Refrigerant Lines

The construction of refrigerant lines using copper piping underscores its significance in maintaining efficient heat transfer within air conditioning units. By optimizing the flow path for refrigerants, these lines enable consistent cooling performance while reducing energy consumption. Manufacturers prioritize the use of high-quality materials like copper to ensure that refrigerant lines meet stringent industry standards for reliability and operational excellence.

Suction and Vapor Lines

The distinction between suction and vapor lines highlights how different components within an air conditioning system rely on specific functionalities provided by copper tubing. The larger insulated line responsible for carrying cool gas—known as the suction line or return line—demonstrates how effective heat transfer facilitated by copper contributes to optimal cooling performance. By integrating suction and vapor lines made from durable materials like pure copper, HVAC systems can achieve maximum efficiency while minimizing environmental impact.

Future Trends and Considerations

Innovations in Copper Pipe Technology

Enhanced Corrosion Resistance

Innovations in copper pipe technology continue to drive advancements in the industry, particularly focusing on enhanced corrosion resistance. Manufacturers are constantly refining the composition of copper pipes to withstand harsh environmental conditions and prolonged usage. By integrating specialized coatings and alloys, these enhanced pipes offer superior protection against corrosion, ensuring longevity and optimal performance for air conditioning units.

Advanced Manufacturing Techniques

The evolution of copper tubing in air conditioning has paved the way for advanced manufacturing techniques that streamline production processes and enhance product quality. Through precision engineering and innovative methodologies, manufacturers can create copper pipes with unparalleled durability and efficiency. This commitment to excellence underscores the industry's dedication to providing cutting-edge solutions for HVAC systems.

Environmental Impact

Sustainability of Copper

The sustainability of copper remains a key consideration in the HVAC industry, emphasizing the material's eco-friendly properties and long-term benefits. Copper is inherently recyclable, reducing waste and minimizing environmental impact during production and disposal. As highlighted by experts in air conditioning technology, "The sustainability of copper aligns with the industry's push towards greener practices, promoting a more environmentally conscious approach to HVAC systems."

Recycling and Reusability

The recycling and reusability of copper pipes play a significant role in promoting circular economy principles within the HVAC sector. By repurposing existing copper materials and minimizing resource consumption, manufacturers can reduce their carbon footprint while maintaining high-quality standards. This emphasis on recycling underscores the industry's commitment to sustainable practices and responsible resource management.

Market Trends

Demand for Copper in HVAC

The demand for copper in HVAC applications continues to rise as industry professionals recognize the unparalleled benefits it offers. With increasing focus on energy efficiency and system reliability, copper remains a preferred choice for air conditioning installations worldwide. As noted by market analysts specializing in HVAC technologies, "The demand for copper reflects its essential role in enhancing system performance and longevity."

Industry Developments

Ongoing industry developments underscore the dynamic nature of the HVAC sector, driving innovation and technological advancements across various applications. From smart cooling solutions to integrated HVAC systems, manufacturers are leveraging copper's unique properties to meet evolving consumer needs effectively. These developments signal a promising future for the industry, marked by continuous growth and innovation.

Copper pipes are indispensable for the optimal functioning of air conditioning systems.

Their exceptional heat transfer capabilities and resistance to corrosion ensure efficient operation and longevity.

Choosing the right copper pipe size is critical for designing an efficient HVAC system, given copper's durability and excellent thermal conductivity.

Copper remains the material of choice in air conditioning units due to its superior heat conductivity and durability.

The sustainability and recyclability of copper highlight its eco-friendly properties, aligning with industry trends towards greener practices.

See Also

Benefits of Opting for Copper Tubing in Air Conditioning

The Importance of Copper Piping for Effective Air Conditioning

Key Advantages of Copper Tubes in Air Conditioning Innovation