Why Insulating Copper Pipes in AC Units Matters

Efficient AC units play a crucial role in maintaining a comfortable indoor environment. Write a 'Why' blog post on 'Importance of insulating copper pipes in air conditioners' to highlight how insulating copper pipes within these systems is essential for optimal performance. These pipes act as vital conduits, facilitating the transfer of refrigerants to enable cooling. By understanding the significance of insulating copper pipes, individuals can enhance their AC's efficiency and longevity while reducing energy consumption. The benefits of insulation extend beyond mere functionality, impacting overall system effectiveness and cost savings.

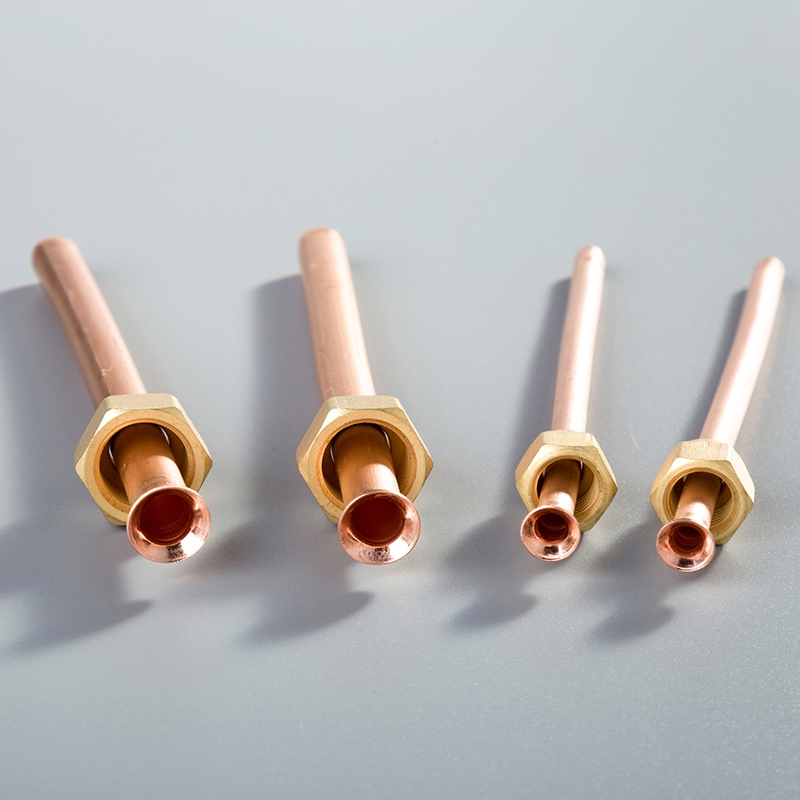

Understanding Copper Pipes in AC Units

Function of Copper Pipes

Heat Transfer Mechanism

Insulating copper pipes can keep the water cooler by reducing heat transfer and maintaining optimal temperature regulation and energy efficiency. Using insulation materials with low thermal conductivity is recommended to minimize heat loss or gain in pipework, enhancing energy efficiency.

Durability and Conductivity

When properly insulated, copper pipes exhibit enhanced durability and conductivity. Insulation protects the pipes from external factors, ensuring longevity and efficient operation. Additionally, insulated copper pipes maintain high conductivity levels, optimizing the overall performance of the AC system.

Benefits of Insulating Copper Pipes

Energy Efficiency

Reduced Energy Consumption: Properly insulating copper pipes in air conditioners significantly reduces energy consumption by preventing heat exchange and maintaining optimal cooling efficiency.

Lower Utility Bills: By insulating copper pipes, individuals can enjoy lower utility bills due to the enhanced energy efficiency of their AC units.

Enhanced System Performance

Improved Cooling Efficiency: Insulating copper pipes improves the overall cooling efficiency of air conditioners by minimizing heat transfer and ensuring consistent temperature regulation.

Prolonged System Lifespan: Insulation contributes to a prolonged lifespan for AC systems as it protects the copper pipes from external factors, reducing wear and tear.

Prevention of Condensation

Avoiding Water Damage: Insulating copper pipes prevents condensation buildup, thereby avoiding potential water damage within the AC unit and maintaining its structural integrity.

Reducing Mold Growth: By eliminating condensation through insulation, the growth of mold within the AC system is minimized, promoting a healthier indoor environment.

Types of Insulation Materials

Foam Insulation

Properties and Benefits

Excellent Thermal Insulation: Foam insulation is known for its exceptional thermal insulation properties, effectively trapping air to maintain optimal temperatures within the copper pipes.

Cost-Effectiveness: Choosing foam insulation can be a cost-effective solution for insulating copper pipes, providing long-term benefits at an affordable price point.

Fire Resistance: Foam insulation offers fire resistance, enhancing safety in case of unexpected incidents.

Installation Process

Measure the Length: Begin by measuring the length of the copper pipe accurately to ensure a proper fit for the foam insulation.

Cut the Insulation: Using appropriate tools, cut the foam insulation material to match the measured length of the pipe precisely.

Secure in Place: Wrap the cut foam insulation around the copper pipe securely, ensuring there are no gaps or exposed areas that could lead to heat loss.

Rubber Insulation

Properties and Benefits

Durable and Flexible: Rubber insulation is highly durable and flexible, adapting well to different pipe shapes and sizes while maintaining its insulating properties.

Moisture Resistance: This type of insulation provides excellent resistance to moisture, preventing condensation buildup on the copper pipes.

Long Lifespan: Rubber insulation has a long lifespan, offering prolonged protection to the copper pipes against external elements.

Installation Process

Prepare the Surface: Clean the surface of the copper pipe thoroughly before installing rubber insulation to ensure proper adhesion.

Apply Adhesive: Use a suitable adhesive designed for rubber insulation to secure it firmly onto the cleaned surface of the copper pipe.

Check for Coverage: Ensure that the rubber insulation covers the entire length of the pipe without any gaps or overlaps that could compromise its effectiveness.

Fiberglass Insulation

Properties and Benefits

Thermal Efficiency: Fiberglass insulation is renowned for its exceptional thermal efficiency, helping maintain consistent temperatures within AC systems.

Non-Combustible: Being non-combustible makes fiberglass insulation a safe choice for environments where fire safety is a priority.

Cost-Effective Solution: Fiberglass insulation offers a cost-effective solution for insulating copper pipes without compromising on performance.

Installation Process

Wear Protective Gear: Prioritize safety by wearing protective gear such as gloves and goggles when handling fiberglass insulation due to its fine fibers.

Cut with Precision: Use sharp tools to cut fiberglass insulation accurately according to the measurements of the copper pipes for a snug fit.

Secure Properly: Securely wrap and fasten fiberglass insulation around each section of the copper pipe, ensuring tight seals to prevent heat loss or gain effectively.

How to Insulate Copper Pipes

Preparation Steps

Measuring Pipe Length

Measure the length of the copper pipes accurately using a measuring tape to ensure a proper fit for the insulation material.

Mark the measurements clearly on the pipes to guide the cutting process and avoid any errors in sizing.

Cleaning the Pipes

Begin by cleaning the surface of the copper pipes thoroughly with a suitable cleaning solution to remove any dirt, dust, or grease.

Ensure that the pipes are completely dry before proceeding with the insulation to promote adhesion and prevent contamination.

Installation Steps

Cutting Insulation Material

Select the appropriate insulation material based on your specific requirements and preferences, considering factors such as thermal conductivity and durability.

Use sharp tools like a utility knife or scissors to cut the insulation material precisely according to the marked measurements on the copper pipes.

Securing Insulation to Pipes

Wrap the cut insulation material around each pipe section firmly, ensuring a snug fit without any gaps or overlaps that could compromise its effectiveness.

Secure the insulation in place using adhesive tape or zip ties, making sure it is tightly sealed along the entire length of the pipe for optimal thermal performance.

Maintenance Tips

Regular Inspection

Conduct regular visual inspections of the insulated copper pipes to check for any signs of wear, damage, or deterioration.

Look out for areas where insulation may be loose or missing, as these can impact energy efficiency and overall system performance.

Replacing Worn Insulation

If you notice any worn-out or damaged insulation during inspections, promptly replace it with new material to maintain effective thermal protection.

Prioritize replacing insulation in high-traffic areas or sections exposed to external elements to prevent heat loss and ensure consistent temperature regulation within your AC system.

Enhancing AC efficiency through insulating copper pipes in air conditioners is paramount for optimal performance. By recapitulating the significance of insulation, individuals can grasp its pivotal role in maintaining energy efficiency and preventing heat exchange. The diverse benefits encompass reduced energy consumption, prolonged system lifespan, and prevention of condensation-related issues. Understanding the types of insulation materials like foam, rubber, and fiberglass empowers homeowners to make informed choices for their AC systems. Ultimately, prioritizing proper insulation ensures a seamless operation and longevity for an efficient AC setup.

See Also

Benefits of Copper Tubing for Efficient Air Conditioning

Importance of Copper Piping for Effective Air Conditioning

Enhance AC Efficiency with Insulated Copper Tubing