Why Insulating Copper Pipes in Home AC Units is Vital

Efficient home AC units play a crucial role in maintaining a comfortable indoor environment. Within these systems, copper pipes serve as essential conduits for refrigerants, facilitating the cooling process. However, to ensure optimal performance and energy efficiency, understanding the significance of insulating these copper pipes is paramount. By exploring the concept of pipe insulation and its direct impact on AC units, homeowners can grasp the importance of this often-overlooked component in their HVAC systems. This blog post will delve into the consequences of not insulating copper pipes in residential AC units, highlighting the potential risks and inefficiencies that can arise.

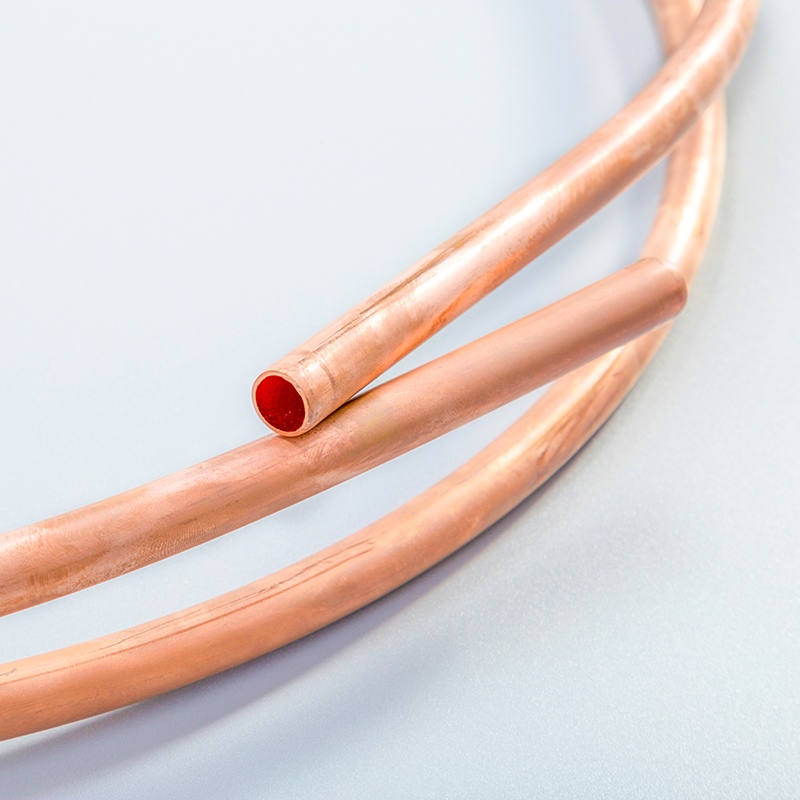

Understanding Copper Pipes in Home AC Units

Role of Copper Pipes

Heat Transfer in AC Systems

Copper, with its exceptional thermal conductivity compared to stainless steel, enables rapid heat transfer within AC systems.

This efficient heat transfer property of copper ensures quick cooling processes, contributing to the overall effectiveness of the air conditioning unit.

Durability and Conductivity of Copper

The durability of copper pipes is noteworthy despite being less durable than stainless steel.

Copper's conductivity plays a vital role in maintaining efficient cooling operations within the HVAC system.

Benefits of Insulating Copper Pipes

Energy Efficiency

Reduced Energy Consumption: Proper insulation on copper pipes significantly reduces heat loss, leading to lower energy consumption and operational costs.

Lower Utility Bills: By insulating the copper pipes in home AC units, homeowners can expect a noticeable decrease in their monthly utility bills due to improved energy efficiency.

Preventing Condensation

Avoiding Water Damage: Insulating copper pipes helps prevent condensation buildup, reducing the risk of water damage to the surrounding areas and preserving the structural integrity of buildings.

Enhancing Pipe Longevity: The insulation acts as a protective barrier, extending the lifespan of copper pipes by shielding them from moisture-related corrosion and wear.

Improved System Performance

Consistent Cooling: Insulated copper pipes ensure consistent cooling performance within the AC unit, maintaining a comfortable indoor environment throughout the year.

Reduced Strain on the AC Unit: With proper insulation, the AC unit operates more efficiently, experiencing less strain and prolonging its overall lifespan.

Types of Insulation Materials

Foam Insulation

Properties and Benefits

Foam Insulation is highly compatible with copper pipes, ensuring a snug fit that effectively prevents heat loss and maintains energy efficiency.

It conforms seamlessly to the shape of the pipes, creating a tight barrier against external elements.

Installation Process

Begin by measuring the length of the copper pipe to determine the required insulation size.

Cut the foam insulation to match the measured length accurately using a sharp utility knife.

Carefully wrap the foam insulation around the copper pipe, ensuring a secure and tight fit.

Seal any gaps or joints with insulation tape for added protection against heat loss.

Rubber Insulation

Properties and Benefits

Rubber Insulation offers excellent thermal resistance properties, ideal for maintaining consistent temperatures within AC systems.

It provides durable protection against moisture and external factors, enhancing the longevity of copper pipes.

Installation Process

Measure and cut the rubber insulation according to the dimensions of the copper pipe.

Wrap the rubber insulation securely around the pipe, ensuring full coverage without any exposed areas.

Use adhesive or specialized tape to seal any seams or edges for optimal insulation performance.

Fiberglass Insulation

Properties and Benefits

Fiberglass Insulation boasts high thermal efficiency, reducing heat transfer and improving overall energy conservation in HVAC systems.

Its lightweight nature makes it easy to handle during installation while offering exceptional durability over time.

Installation Process

Measure and cut fiberglass insulation to match the length of each copper pipe accurately.

Gently slide the fiberglass material over the pipe, ensuring a snug fit without compressing it excessively.

Secure the ends with tape or zip ties to prevent any movement that could compromise its insulating properties.

How to Insulate Copper Pipes

Preparation

Gathering Materials

Acquire the necessary insulation material based on the type suitable for your copper pipes, such as foam, rubber, or fiberglass.

Ensure you have a utility knife for cutting the insulation to the required size accurately.

Prepare insulation tape or clamps to secure the insulating material effectively.

Measuring and Cutting Insulation

Measure the length of each copper pipe that requires insulation using a measuring tape.

Mark the measured length on the insulation material and cut it precisely to fit each pipe snugly.

Double-check the measurements to avoid any gaps in coverage that could compromise the effectiveness of the insulation.

Installation Steps

Applying Insulation

Start by placing the cut insulation material around the copper pipe, ensuring a tight and secure fit without any exposed areas.

Press down gently on the insulation to guarantee proper adhesion and coverage along the entire length of the pipe.

Smooth out any wrinkles or folds in the insulation to maintain consistent thickness and thermal protection.

Securing with Tape or Clamps

Use insulation tape to wrap around any seams or joints where two pieces of insulation meet, creating a seamless barrier against heat loss.

Secure loose ends of the insulation with clamps to prevent shifting or movement that could lead to gaps in coverage.

Check all connections and edges for tightness and reinforcement, ensuring maximum efficiency in insulating your copper pipes.

Maintenance Tips

Regular Inspections

Conduct routine visual inspections of your insulated copper pipes to check for any signs of wear, damage, or displacement.

Look out for tears, gaps, or loosened sections in the insulation that may compromise its effectiveness over time.

Address any issues promptly by repairing or replacing damaged insulation to maintain optimal thermal performance.

Replacing Worn Insulation

If you notice worn-out or deteriorated sections of insulation during inspections, plan for timely replacement to uphold efficient heat retention.

Remove old or damaged insulation carefully by unwrapping it from the copper pipe and disposing of it properly.

Install new insulation following the same steps as initial installation, ensuring a snug fit and complete coverage for enhanced energy efficiency.

By following these preparation steps, installation procedures, and maintenance tips diligently, homeowners can effectively insulate their copper pipes in home AC units, promoting energy efficiency and prolonging system longevity with minimal heat loss risks.

Insulating copper pipes in home AC units is a fundamental step towards ensuring long-term savings and system performance. By recapitulating the significance of proper insulation, homeowners can grasp the multifaceted benefits that extend beyond mere cost savings. Expert guidance from reputable companies like Hayes Plumbing and Neo Thermal Insulation empowers Canadian homeowners in regions like Oshawa to safeguard their structures against harsh winter conditions. Taking action to insulate copper pipes not only enhances energy efficiency but also shields against environmental damage, guaranteeing uninterrupted functionality even in extreme temperatures. Make the wise choice today for a more efficient and durable HVAC system!

See Also

Benefits of Opting for Copper Tubing in Air Conditioning

The Importance of Copper Piping for Effective Air Conditioning

Key Advantages of Copper Tubes in Air Conditioning Innovation

Enhance Air Conditioner Performance with Copper Tubing Insulation Tips

The Impact of Copper Piping on Air Conditioning Transformation