Install Air Conditioning Copper Pipes Easily

When it comes to air conditioning installations, copper pipes are your best choice. Their natural bactericidal properties ensure a clean environment, while their resistance to corrosion guarantees longevity. Additionally, copper pipes offer better energy efficiency, keeping your space cool effectively. In this blog, we will delve into the seamless process of installing air conditioning copper pipe connecting pipes, ensuring a hassle-free experience for you.

Materials and Tools Needed

To ensure a smooth installation process of air conditioning copper pipe connecting pipes, it is essential to have the right materials and tools at hand.

Essential Materials

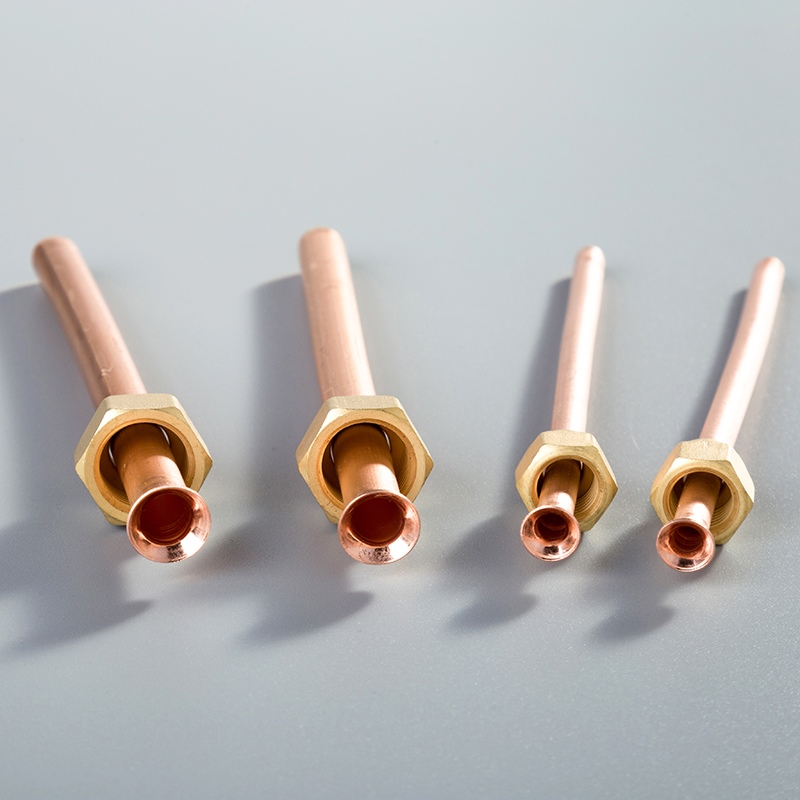

High-quality copper pipes (e.g., Mexflow by Mehta Tubes Limited)

Begin by selecting high-quality copper pipes such as Mexflow by Mehta Tubes Limited. These pipes are known for their durability and reliability in air conditioning installations.

Next, gather the necessary fittings and joints to connect the copper pipes securely. This ensures a leak-free system that functions efficiently.

Lastly, don't forget to acquire insulation materials to cover the copper pipes. Insulation helps in maintaining the temperature of the refrigerant within the pipes, improving overall energy efficiency.

Necessary Tools

Pipe cutter

A pipe cutter is an indispensable tool for accurately cutting the copper pipes to the required length. Precision is key in ensuring a proper fit during installation.

Flaring tool

The flaring tool is essential for shaping the pipe ends, allowing for seamless connections with fittings and joints. This step guarantees a secure and leak-proof setup.

Brazing torch

Utilize a brazing torch to join the copper pipes with fittings using heat. This method creates strong bonds that withstand pressure and temperature changes effectively.

Nitrogen tank for testing

Finally, have a nitrogen tank ready for testing purposes. Nitrogen testing helps identify any leaks in the system before operation, ensuring optimal performance.

Step-by-Step Installation Guide

Preparation

Measuring the required length of copper pipes

To start the installation process, measure the necessary length of copper pipes accurately. This step ensures a precise fit and seamless connection for your air conditioning system.

Cutting the pipes to size

Next, cut the copper pipes to the measured length using a reliable pipe cutter. This tool guarantees clean and accurate cuts, essential for a successful installation.

Connecting the Pipes

Flaring the pipe ends

After cutting, it's time to flare the ends of the copper pipes using a flaring tool. This process shapes the pipe ends for secure connections with fittings, ensuring a leak-free system.

Using special joints for secure connections

Utilize special joints designed for connecting air conditioning copper pipe connecting pipes without welding. These joints provide quick and durable connections that are essential for a reliable setup.

Securing the Installation

Ensuring all connections are tight and secure

Double-check all connections to guarantee they are tight and secure. Properly secured connections prevent leaks and ensure efficient operation of your air conditioning system.

Insulating the pipes to prevent energy loss

Lastly, insulate the copper pipes to prevent energy loss and maintain optimal efficiency. Proper insulation helps in preserving the cooling capacity of your AC unit while reducing energy consumption.

Specific Considerations

Switching Refrigerants

Need to replace copper lines

When considering a switch in refrigerants, it is crucial to address the necessity of replacing copper lines. Different refrigerants may require specific piping materials for optimal performance and safety. Ensuring that the copper lines are compatible with the new refrigerant is essential to prevent any potential issues in the system.

Compatibility with different refrigerants

The compatibility of copper pipes with various refrigerants plays a significant role in the efficiency and longevity of your air conditioning system. Understanding the compatibility ensures that the system operates smoothly without any adverse effects on performance or durability. Always verify that the chosen copper pipes are suitable for the specific refrigerant being used to maintain an efficient cooling process.

Concealed Copper Pipe Installation

Benefits of concealed installation

Opting for a concealed copper pipe installation offers several advantages for your air conditioning setup. Concealing the pipes not only enhances the aesthetics of your space but also provides protection against external elements, reducing the risk of damage or corrosion. Additionally, a concealed installation promotes better airflow and circulation within your AC unit, contributing to its overall efficiency and performance.

Steps to achieve a concealed setup

Achieving a concealed copper pipe installation involves careful planning and execution. Start by determining the optimal routing for the pipes, ensuring they are hidden from view while maintaining accessibility for maintenance purposes. Securely fasten the pipes in place using appropriate fixtures to prevent any movement or vibrations that could affect their functionality. Finally, conceal the pipes using suitable covers or casings that blend seamlessly with your interior design, creating a polished and professional look.

Tips for Professional and Efficient Installation

Importance of Nitrogen Testing

To ensure a successful installation of air conditioning copper pipe connecting pipes, conducting nitrogen testing is crucial. This step helps in detecting any potential leaks in the system before operation, guaranteeing optimal performance.

How to perform nitrogen testing

Begin by connecting the nitrogen tank to the system.

Pressurize the pipes with nitrogen gas.

Use a pressure gauge to monitor any pressure drops, indicating possible leaks.

Identify and fix any leaks found during testing promptly.

Benefits of nitrogen testing for leak detection

Detecting leaks early prevents future issues.

Ensures that the system operates efficiently without any disruptions.

Maintains the integrity of the installation for long-term use.

Potential Additional Costs

When planning for an air conditioning installation using copper pipes, it's essential to consider potential additional costs that may arise throughout the process.

Cost of high-quality materials

Invest in high-quality copper pipes to guarantee durability and efficiency.

Consider the cost of necessary fittings and insulation materials for a complete setup.

Prioritize quality to avoid frequent replacements or repairs in the future.

Professional installation fees

Hiring professionals for the installation ensures precision and expertise.

Expect additional fees for labor and specialized services provided by experts.

The investment in professional installation pays off with a reliable and well-functioning air conditioning system.

Recap of the Benefits: Copper pipes are praised for their durability and energy efficiency, ensuring a long-lasting and cost-effective air conditioning system. The natural properties of copper pipes maintain a clean environment while providing superior cooling performance.

Summary of the Installation Process: Installing air conditioning copper pipe connecting pipes involves precise measurements, secure connections, and thorough insulation. Each step contributes to an efficient and reliable AC setup that enhances your comfort.

Final Tips for Success: Prioritize quality materials like Mexflow by Mehta Tubes Limited, follow proper installation steps diligently, and conduct nitrogen testing for leak prevention. These practices guarantee a seamless operation of your air conditioning system.

Encouragement to Seek Professional Help: If you encounter challenges during installation or prefer expert assistance, don't hesitate to consult professionals for a smooth and successful setup.

See Also

Effortless Guide: Installing Copper Tubes for Air Conditioning Expertly

Benefits of Opting for Copper Tubing in Air Conditioning

The Impact of High-Quality Copper Pipes on Air Conditioning

Key Factors in the Copper Pipes Revolutionizing Air Conditioning

The Importance of Pure Copper Pipes in Effective Air Conditioning