Step-by-Step Guide: How to Install Copper Pipes in Air Conditioners

How to Install Copper Pipes in Air Conditioners

When it comes to air conditioning installations, the installation of copper pipes plays a crucial role in ensuring optimal performance and longevity. Copper, known for its superior heat conductivity and durability, is the preferred choice for air conditioning systems. By utilizing copper pipes, one can benefit from efficient cooling, reduced energy consumption, and lower greenhouse gas emissions. The steps involved in installing these pipes are essential to guarantee a seamless operation of the air conditioner. Let's delve into the significance of proper installation methods and the advantages of using copper pipes in air conditioners.

Tools and Materials Needed

To successfully install copper pipes in air conditioners, one must have the necessary tools and materials at hand. These items are crucial for ensuring a seamless installation process that guarantees optimal performance of the air conditioning system.

Essential Tools

The Pipe Cutter is essential for precisely cutting the copper pipes to the required lengths, allowing for accurate fittings.

Utilize the Brazing Torch to create strong joints between copper pipes, ensuring a secure connection that prevents leaks.

The Flaring Tool is indispensable for creating flared ends on the copper pipes, facilitating easy connections and enhancing overall stability.

Required Materials

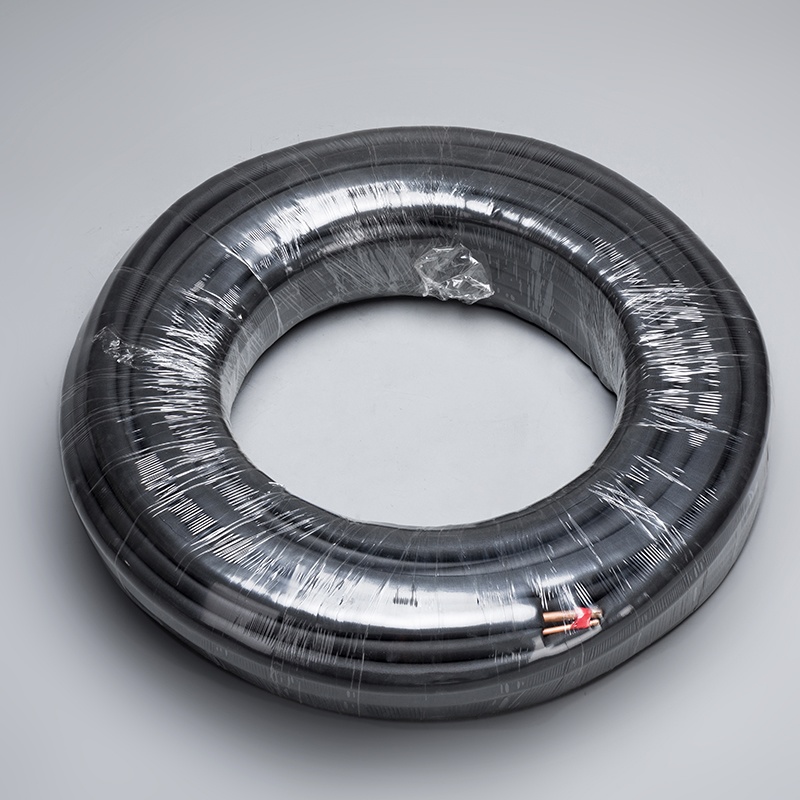

Copper Pipes are the backbone of any air conditioning system, known for their durability and efficient cooling properties.

Flux and Solder are vital for brazing joints, providing a strong bond between copper pipes that is resistant to high temperatures and pressure.

Pipe Insulation is crucial for maintaining temperature consistency within the system, preventing energy loss and ensuring efficient operation.

By having these tools and materials ready, individuals can proceed with confidence in installing copper pipes effectively in their air conditioning units.

Step-by-Step Installation

Measure and Cut Pipes

To ensure a precise fit, Measuring the Length of the copper pipes is the initial step in the installation process. This guarantees that the pipes are cut to the exact specifications required for a seamless connection. Once the measurements are taken, Cutting the Pipes accurately follows. Using a pipe cutter, individuals can easily trim the copper pipes to match the designated lengths without any room for error.

Prepare the Pipes

After cutting, it is crucial to Cleaning the Ends of the copper pipes thoroughly. This step removes any debris or impurities that could hinder a secure connection. Following this, Applying Flux comes into play. By applying flux to the cleaned ends of the pipes, individuals can ensure a strong bond during brazing, enhancing the overall stability of the joints.

Join the Pipes

The next step involves Brazing the Joints, where individuals use a brazing torch to create robust connections between copper pipes. This method ensures that the joints are sealed securely, preventing any potential leaks in the system. Subsequently, it is essential to conduct a thorough inspection by Checking for Leaks post-brazing to guarantee that all connections are airtight and leak-free.

Insulate the Pipes

Applying Insulation

To maintain optimal performance and efficiency of HVAC systems, it is crucial to apply proper insulation to copper pipes. Applying insulation to the pipes helps in preventing heat loss and maintaining consistent cooling throughout the system. This step not only enhances energy efficiency but also prolongs the lifespan of the air conditioning unit.

Start by selecting high-quality insulation materials that are suitable for copper pipes. These materials should have excellent thermal properties to effectively regulate temperature.

Carefully wrap the insulation around the copper pipes, ensuring a snug fit without any gaps. This tight seal is essential for preventing any heat exchange with the surrounding environment.

Secure the insulation in place using appropriate fasteners or tape. This step guarantees that the insulation remains intact and does not shift over time, maintaining its effectiveness.

Securing the Insulation

After applying insulation to the copper pipes, it is essential to secure it properly to avoid any potential issues in the future. Properly securing the insulation ensures that it stays in place and continues to provide optimal thermal protection.

Double-check all connections and joints where insulation meets to guarantee a seamless coverage along the entire length of the copper pipes.

Regularly inspect the insulation for any signs of wear or damage, such as tears or compression. Promptly replace any damaged sections to uphold efficient cooling performance.

Conduct periodic maintenance checks on the insulation to verify its integrity and effectiveness. By maintaining well-insulated copper pipes, individuals can enjoy consistent cooling comfort while maximizing energy savings.

Final Checks and Testing

Inspect the Installation

Upon completing the installation of copper pipes in air conditioners, a thorough examination is imperative to ensure flawless operation. Visual inspection serves as the initial step, allowing individuals to visually assess all connections and joints for any irregularities. By meticulously examining each component, one can verify the precision of the installation process and identify any potential issues that may compromise system efficiency.

Subsequently, conducting a pressure test is essential to validate the integrity of the entire system. This test involves pressurizing the copper pipes to detect any leaks or weaknesses in the connections. By subjecting the system to varying pressure levels, individuals can ascertain its ability to withstand operational demands without experiencing detrimental leaks.

Start the Air Conditioner

Following successful inspection and testing procedures, initiating the air conditioner is paramount to evaluate its functionality. The initial run allows individuals to observe how effectively the system cools while ensuring that all components operate harmoniously. Monitoring various performance indicators during this phase enables users to gauge the system's efficiency and address any anomalies promptly.

Continuously monitoring performance post-installation is crucial for maintaining optimal functionality. Regularly assessing cooling efficiency, energy consumption, and overall performance metrics ensures that the air conditioner operates at peak capacity. By vigilantly monitoring these aspects, individuals can address any deviations from expected performance levels promptly.

Recapping the key steps in installing copper pipes is crucial for ensuring a successful air conditioning system. By meticulously measuring, cutting, preparing, joining, and insulating the pipes, individuals can guarantee efficient cooling and reduced energy consumption. Emphasizing the significance of following this comprehensive guide is essential to achieve optimal performance. Should complexities arise during the installation process, seeking professional assistance is highly recommended to ensure a seamless operation of the air conditioner.

See Also

Effortless Guide: Installing Copper Tubing for Air Conditioning

Benefits of Selecting Copper Tubing for Air Conditioning

Comprehensive DIY Manual for Repairing Copper Tubing Holes in AC

Revealing the Development of Copper Tubing in Air Conditioning

Exploring the Influence: Copper Tubing in Air Conditioning Systems