How to Insulate Copper Pipes in Air Conditioning Systems

How to Insulate Copper Pipes in Air Conditioning Systems

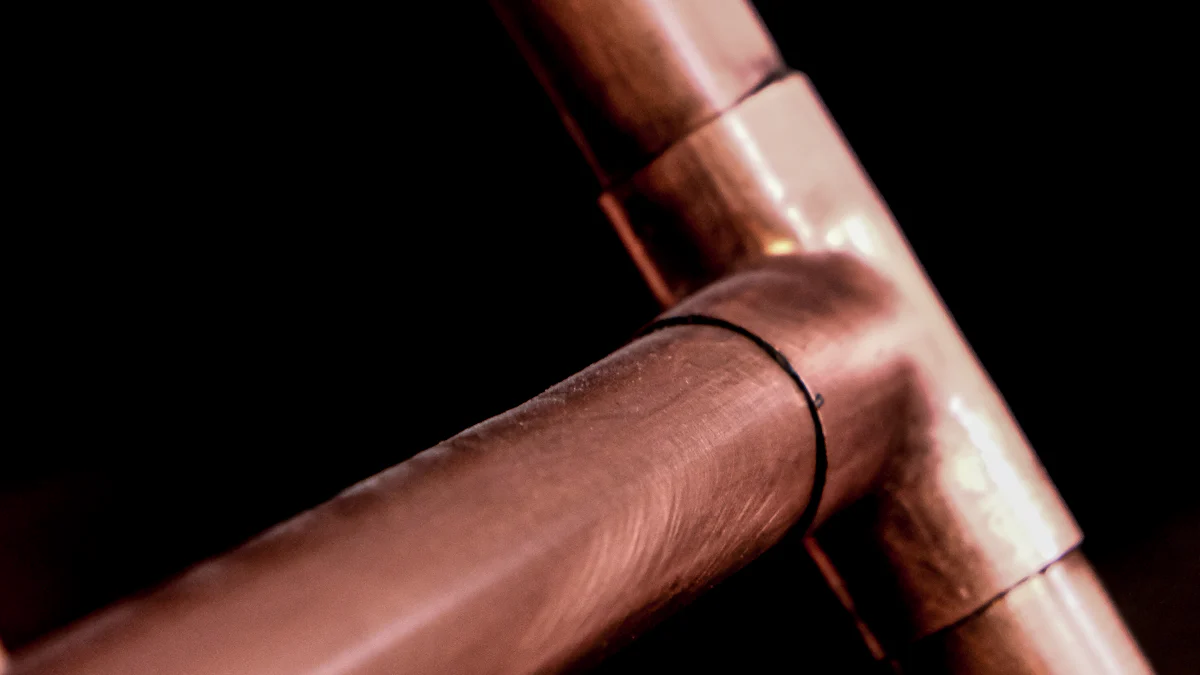

Insulating copper pipes in air conditioning systems is crucial for homeowners looking to save on energy costs and maintain efficient cooling. By preventing condensation buildup, significant energy savings can be achieved over time. The insulation not only reduces heat loss but also promotes energy conservation, ultimately leading to lower utility bills. In this blog, the focus will be on the benefits of insulating copper pipes and the methods involved in ensuring optimal efficiency.

Materials Needed

When it comes to insulating copper pipes in air conditioning systems, having the right materials is essential for a successful insulation process. Here are the key components required to effectively insulate your copper pipes:

Foam Tubing

Foam tubing is a versatile and cost-effective solution for insulating copper pipes. Foam Pipe Insulation Tape is a popular choice, offering excellent thermal insulation properties. This foam tape comes in various sizes and thicknesses, ensuring a snug fit around your pipes. The Foam Tube itself acts as a barrier, preventing heat loss and maintaining water temperature. By selecting the appropriate size based on your pipe diameter, you can ensure optimal coverage and insulation efficiency.

Insulation Tape

Insulation tape plays a crucial role in securing the foam tubing around the copper pipes. Foam Pipe Insulation Tape is designed to withstand extreme temperatures, ranging from -50°C to 120°C. It provides an additional layer of protection against heat loss and condensation buildup. Understanding the different types of insulation tape available and their application techniques is vital for achieving long-lasting insulation results.

Additional Tools

In addition to foam tubing and insulation tape, several tools are necessary for a smooth insulation process. A utility knife helps in cutting the foam tubing to the required length with precision. A measuring tape ensures accurate measurements for a snug fit around the pipes. Lastly, Gaffer tape is used to secure the ends of the foam tubing and provide added reinforcement.

By gathering these materials and tools beforehand, you can streamline the insulation process and ensure that your copper pipes are effectively insulated for improved energy efficiency.

Step-by-Step Insulation Process

Preparation

Measuring the Pipes

To initiate the insulation process effectively, start by accurately measuring the copper pipes. Ensuring precise measurements is crucial for selecting the appropriate foam tubing size and achieving a snug fit. By measuring the pipes meticulously, you set a solid foundation for optimal insulation coverage.

Cleaning the Pipes

Before proceeding with insulating the copper pipes, it's essential to clean them thoroughly. Remove any dirt, dust, or debris that may hinder the adhesion of the foam tubing and insulation tape. A clean surface promotes better contact and enhances the overall insulation effectiveness.

Applying Foam Tubing

Cutting the Foam Tubing

Once the pipes are measured and cleaned, proceed to cut the foam tubing to match the measured length accurately. Utilize a sharp utility knife for precision cutting, ensuring smooth edges for a seamless fit around the copper pipes. Cutting the foam tubing with care guarantees a tailored insulation solution.

Securing the Foam Tubing with Tape

After cutting the foam tubing to size, securely fasten it around the copper pipes using high-quality gaffer tape. Ensure that the foam tubing is tightly wrapped without any gaps or overlaps along its length. Properly securing the foam tubing with tape prevents slippage and maintains consistent insulation coverage.

Using Insulation Tape

Wrapping the Tape Around the Pipes

Following the application of foam tubing, proceed to wrap insulation tape around it in a spiral manner. The insulation tape acts as an additional layer of protection against heat loss and condensation buildup. Ensure a tight wrap around the foam tubing to enhance its insulating properties effectively.

Ensuring Full Coverage

As you wrap insulation tape around the copper pipes, pay close attention to achieving full coverage along their entire length. Avoid leaving any exposed areas that could compromise insulation efficiency. By ensuring complete coverage with insulation tape, you guarantee comprehensive protection against temperature fluctuations and energy loss.

Implementing these step-by-step instructions ensures a thorough and efficient insulation process for your copper pipes in air conditioning systems, promoting energy savings and enhancing system performance.

Tips for Effective Insulation

Insulating Cold Water Pipes

When it comes to insulating cold water pipes, utilizing white, silver, or foil pipe tape can significantly enhance the efficiency of your plumbing system. These specialized tapes provide a protective barrier that helps maintain water temperature and prevents heat loss. By wrapping the pipes with white, silver, or foil pipe tape, you create a shield against external elements and ensure consistent water flow even in low temperatures.

Preventing Freezing

Preventing freezing in your plumbing system is crucial to avoid costly damages and disruptions. One effective solution is using electrically powered antifreeze tape, which generates heat to keep the pipes above freezing temperatures. By strategically installing electrically powered antifreeze tape along vulnerable areas, such as exposed outdoor pipes or those located in unheated spaces, you can safeguard your plumbing system from freezing during cold weather conditions.

Insulating in Tight Spaces

Insulating copper pipes in tight spaces requires innovative solutions to ensure proper coverage and protection. Utilizing pipe wrap or tape material specifically designed for compact areas can effectively enhance insulation performance. The flexibility and durability of these materials allow for seamless application around bends and corners, providing comprehensive insulation without compromising space constraints.

By implementing these tips for effective insulation, homeowners can optimize energy efficiency, prevent potential damages from freezing, and ensure reliable performance of their plumbing systems. Whether insulating cold water pipes with specialized tape or using innovative solutions for tight spaces, investing in proper insulation measures can lead to long-term cost savings and enhanced system functionality.

Reducing Costs: Insulating copper pipes leads to significant cost savings for homeowners. By minimizing heat loss, the workload on water heaters decreases, resulting in lower energy consumption and reduced utility bills.

Long-term Benefits: Beyond immediate savings, insulating copper pipes offers long-term advantages. It prevents freezing, improves efficiency, and protects the plumbing system from environmental damage.

Enhanced Comfort: Insulated pipes maintain consistent water temperatures, ensuring quick access to hot water and creating a comfortable living environment for residents.

Implementing proper insulation measures not only saves money but also enhances energy efficiency and overall comfort in your home.

See Also

Enhance Air Conditioner Performance with Copper Pipe Insulation

Benefits of Selecting Copper Pipes for Air Conditioners

The Transformation of Air Conditioning with Pure Copper Pipes

Exploring Optimal Insulation Solutions for Copper Pipes

The Importance of Pure Copper Pipes in Air Conditioning Efficiency