Investigate Quality Assurance in 1/4 3/8 Twin Copper Pipe Coils

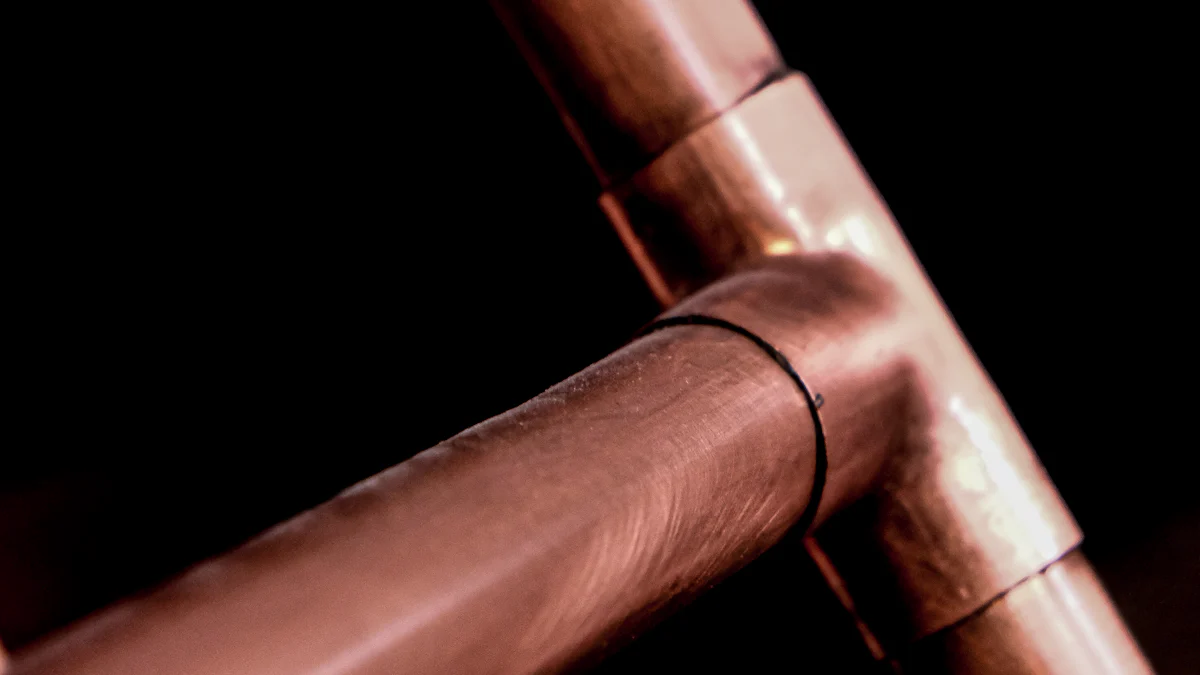

Quality assurance plays a pivotal role in ensuring the effectiveness of 1/4 and 3/8 twin copper pipe coils. These coils are essential components in various applications, ranging from plumbing to refrigeration. Understanding the significance of maintaining high standards in copper pipe coil production is crucial for both manufacturers and consumers. This blog aims to investigate the effectiveness of quality assurance methods in modern 1/4 3/8 twin copper pipe coils, shedding light on their importance and impact on product reliability.

Quality Assurance Methods

Visual Inspection is a crucial step in ensuring the quality of 1/4 and 3/8 twin copper pipe coils. It involves meticulously examining the Surface Quality to detect any imperfections that may compromise the integrity of the coils. Dimensional Accuracy is also assessed during this process to verify that the coils meet the precise measurements required for their intended applications.

Non-Destructive Testing methods, such as Ultrasonic Testing and Eddy Current Testing, are employed to further evaluate the quality of the copper pipe coils without causing any damage. Ultrasonic Testing utilizes high-frequency sound waves to detect internal flaws or inconsistencies within the coils, ensuring their structural integrity. On the other hand, Eddy Current Testing uses electromagnetic induction to identify surface defects or variations in conductivity, providing valuable insights into the overall quality of the coils.

Destructive Testing techniques like Tensile Testing and Hardness Testing involve subjecting samples of copper pipe coils to extreme conditions to assess their mechanical properties. Tensile Testing measures the maximum stress a coil can withstand before breaking, offering valuable data on its strength and durability. Hardness Testing, on the other hand, evaluates the resistance of the coil to indentation or deformation, providing essential information about its hardness and robustness.

Incorporating these rigorous Quality Assurance Methods ensures that manufacturers can deliver high-quality 1/4 and 3/8 twin copper pipe coils that meet industry standards and exceed customer expectations.

Industry Standards

When it comes to 1/4 and 3/8 twin copper pipe coils, ensuring compliance with industry standards is paramount. These standards serve as benchmarks for quality and safety in various applications, including plumbing and gasfitting.

Plumbing Standards are crucial for regulating the installation and maintenance of plumbing systems. They outline specific requirements for materials, design, and construction to guarantee optimal performance. By adhering to these standards, manufacturers can ensure that their copper pipe coils meet the necessary criteria for use in plumbing applications.

Similarly, Gasfitting Standards play a vital role in ensuring the safe installation and operation of gas systems. These standards cover aspects such as material compatibility, pressure ratings, and leak prevention measures. By following gasfitting standards, manufacturers can provide high-quality copper pipe coils that are suitable for gas distribution systems.

Moving on to Refrigeration Quality, durability and versatility are key factors that define the performance of copper pipe coils in refrigeration applications. The durability of these coils ensures long-term reliability in demanding environments, while their versatility allows for use in a wide range of refrigeration systems.

By prioritizing compliance with industry standards and focusing on refrigeration quality, manufacturers can deliver 1/4 and 3/8 twin copper pipe coils that meet the highest quality requirements across different industries.

Benefits of Quality Assurance

Ensuring quality assurance in the production of 1/4 and 3/8 twin copper pipe coils offers significant benefits that contribute to their long service life and enhance consumer confidence. Corrosion resistance is a key advantage of high-quality copper pipe coils, providing protection against environmental factors that could compromise their integrity. The inherent strength of these coils ensures durability and reliability in various applications.

By prioritizing quality assurance, manufacturers instill consumer confidence through the reliability and safety of their products. Consumers can trust that copper pipe coils manufactured with stringent quality control measures will perform as expected, meeting industry standards for functionality and safety. The reliability of these coils lies in their consistent performance over time, offering peace of mind to users across different industries. Moreover, the emphasis on safety guarantees that copper pipe coils meet all necessary requirements to prevent potential hazards and ensure user well-being.

To ensure the quality of 1/4 and 3/8 twin copper pipe coils, manufacturers must rigorously implement quality assurance methods. These methods, such as visual inspection and non-destructive testing, play a crucial role in maintaining the integrity of the coils.

Adhering to industry standards is essential for guaranteeing the reliability and safety of copper pipe coils in various applications. Compliance with plumbing and gasfitting standards ensures that the coils meet the necessary requirements for optimal performance.

Future developments in quality assurance are on the horizon, with innovations in materials science enhancing the durability and longevity of copper tubes. Antimicrobial copper pipes are also gaining traction due to growing sustainability concerns in the market.

By continuously improving quality assurance processes and staying abreast of industry trends, manufacturers can meet the evolving demands for high-quality 1/4 and 3/8 twin copper pipe coils across different sectors.

See Also

Exploring Innovative Quality Assurance Methods for Copper Pipe Coils

Revealing the Hidden Quality Control Strategies for Copper Pipe Coils

Achieving Excellence in Quality Control for Copper Pipe Coils

Exploring the Future: Twin Copper Pipe Coils in Construction Projects