Top Tips for Maintaining AC Copper Pipes

Write a 'Tips' blog post on 'Maintenance Tips for Air Conditioning Copper Pipes'

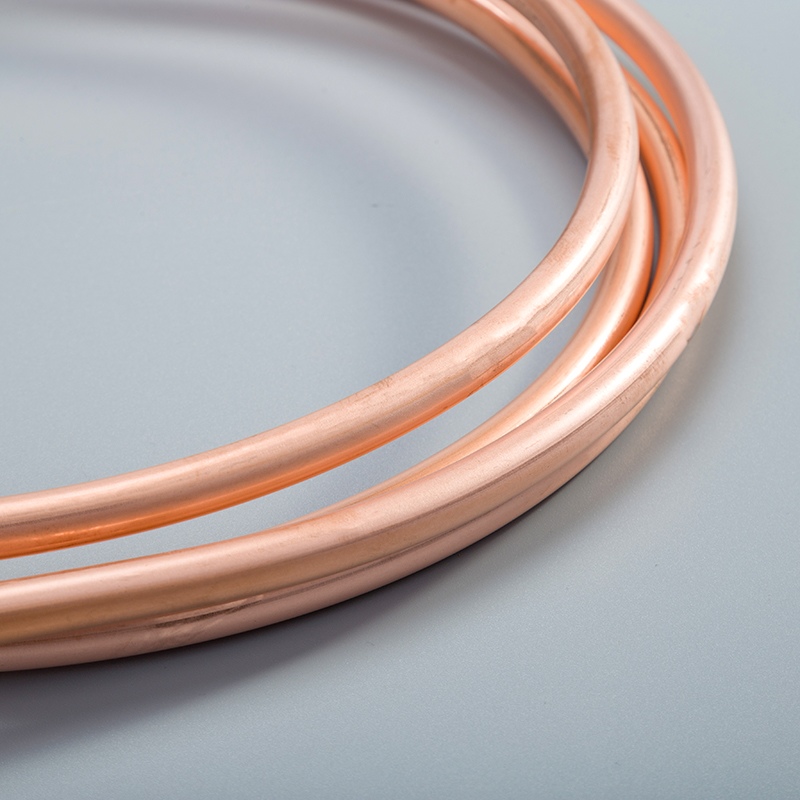

Maintaining AC copper pipes is crucial for ensuring the efficient operation of your air conditioning system. Regular maintenance not only prevents common issues such as leaks and corrosion but also promotes energy savings through rapid heat transfer. By taking care of your copper pipes, you contribute significantly to reducing overall energy consumption. Embracing these maintenance tips for air conditioning copper pipes will help you enjoy a comfortable indoor environment while maximizing the lifespan of your cooling system.

Regular Inspection

Inspecting your AC copper pipes regularly is essential to ensure their optimal performance and longevity. By conducting thorough checks, you can identify potential issues early on and prevent costly repairs down the line.

Visual Inspection

When visually inspecting your copper pipes, focus on two main aspects: Checking for Corrosion and Identifying Leaks.

Checking for Corrosion

Look for any signs of corrosion on the surface of the copper pipes.

Use a mild detergent solution and a soft brush to gently clean off any corrosion.

Corrosion can weaken the pipes over time, leading to leaks and inefficiencies in your air conditioning system.

Identifying Leaks

Check for any visible leaks along the length of the copper pipes.

Pay close attention to joints and connections where leaks are more likely to occur.

Addressing leaks promptly can prevent water damage and maintain the effectiveness of your cooling system.

Professional Inspection

While regular visual inspections are crucial, Professional Inspections provide a more in-depth analysis of your AC copper pipes' condition.

Frequency of Professional Checks

Schedule professional inspections at least once a year to assess the overall health of your copper piping.

Professionals have specialized tools and knowledge to detect underlying issues that may not be visible during routine checks.

What to Expect During a Professional Inspection

Professionals will conduct pressure tests to check for leaks or weak points in the piping system.

They will also assess the insulation around the pipes to ensure optimal efficiency.

Professional inspections complement your regular maintenance efforts, ensuring that your air conditioning system operates smoothly throughout its lifespan.

Cleaning the Pipes

When maintaining your air conditioning system, Cleaning the Pipes is a crucial step to ensure optimal performance and longevity. By keeping your AC copper pipes clean, you can prevent issues like blockages and inefficiencies that may arise from dirt or debris buildup.

External Cleaning

Tools Needed

Soft Brush: Use a soft brush to gently remove dust and dirt from the exterior surface of the copper pipes.

Cloth: A cloth can be handy for wiping down the pipes after brushing to ensure they are free of any remaining debris.

Step-by-Step Cleaning Process

Start by inspecting the copper pipes for any visible dirt or debris accumulation.

Gently brush off the dust using a soft brush, moving in a circular motion along the length of the pipes.

Wipe down the pipes with a cloth to remove any remaining particles and leave them clean and free of obstructions.

Internal Cleaning

Importance of Flushing the System

Flushing the system is essential to remove any internal buildup that could hinder proper airflow and heat transfer within the copper pipes.

Regular flushing helps maintain optimal efficiency and prevents blockages that could lead to system malfunctions.

Safe Cleaning Solutions

Aflex-Eco Insulation Foam: Consider using Aflex-Eco, a nitrile insulation foam, to cover and insulate your copper pipes effectively.

XLPE Insulation Tubing: XLPE insulation tubing is another option for insulating copper pipes, offering various wall thicknesses for different pipe diameters.

Preventive Measures

Insulation

Types of Insulation Materials

Nitrile Insulation Foam: Aflex-Eco, a nitrile insulation foam, is a highly effective material for insulating AC copper pipes. It comes in various wall thicknesses to cater to different pipe diameters.

XLPE Insulation Tubing: Another option for insulating copper pipes is XLPE insulation tubing. This tubing offers versatility with different wall thickness options suitable for various pipe sizes.

How to Properly Insulate Pipes

Begin by selecting the appropriate insulation material based on the diameter of your copper pipes.

Measure the length of the pipes accurately to ensure complete coverage with the chosen insulation material.

Cut the insulation material to size and wrap it securely around the pipes, ensuring no gaps or exposed areas.

Seal any joints or connections with adhesive tape to enhance insulation effectiveness and prevent heat loss.

Protective Coatings

Benefits of Coatings

Enhanced Durability: Applying protective coatings on AC copper pipes can significantly increase their lifespan by shielding them from external elements and corrosion.

Improved Efficiency: Coatings help maintain optimal heat transfer within the pipes, promoting energy efficiency and reducing cooling system strain.

Application Process

Clean the surface of the copper pipes thoroughly to remove any dirt, debris, or corrosion before applying the protective coating.

Select a high-quality protective coating suitable for HVAC systems that offers corrosion resistance and thermal protection.

Apply the coating evenly along the entire length of the copper pipes using a paintbrush or spray method, ensuring complete coverage.

Allow sufficient drying time as per the manufacturer's instructions before restoring your air conditioning system to operation.

Addressing Common Issues

Fixing Minor Leaks

Temporary Fixes

Apply a specialized sealant to the leaking area on the copper pipes.

Use a pipe repair clamp to secure the leak temporarily.

Wrap the affected area with rubber tape for a quick fix.

Permanent Solutions

Replace the damaged section of the copper pipes with new piping material.

Solder the joints securely to prevent future leaks.

Install a protective sleeve over the repaired section for added durability.

Dealing with Corrosion

Identifying Corrosion Early

Conduct regular visual inspections to spot any signs of corrosion promptly.

Look for greenish or bluish discoloration on the surface of the copper pipes.

Use a magnifying glass to detect early stages of corrosion that may be less visible.

Treatment Options

Clean the corroded areas using a mild detergent solution and a soft brush.

Apply an anti-corrosion coating to protect the copper pipes from further damage.

Consider replacing severely corroded sections with new piping material for long-term prevention.

Investigating the impact of Pure Copper pipes on air conditioning cooling capabilities reveals their pivotal role in optimizing systems. These pipes, known for superior strength and corrosion resistance, ensure efficient heat transfer for optimal performance. The antimicrobial benefits of copper contribute to a healthier environment while enhancing system efficiency. Research findings emphasize minimal maintenance needs due to copper's durability, reducing upkeep costs. Studies highlight energy savings through rapid heat transfer with Pure Copper pipes, making them a cost-effective choice for efficient air conditioning systems. Opt for regular maintenance to enjoy long-term reliability and energy-efficient cooling solutions.

See Also

Key Maintenance Tips for Copper Tubing Coils

Comprehensive Manual for Copper Pipe Performance

Crucial Advice for 1/4 Copper Tube Connectors

Benefits of Opting for Copper Tubing in AC

Revealing the Prime Advantages of Copper Tubing for AC Units