Master Copper Pipe Fittings: Your Ultimate DIY Guide

Copper pipe fittings play a vital role in plumbing systems, ensuring leak-proof connections and efficient operations. Understanding the significance of copper pipe fittings is crucial for anyone involved in plumbing projects. This guide aims to provide a comprehensive overview of these essential components, covering their types, sizes, and installation techniques. For more detailed information on copper pipe sizes, you can visit https://copperpipe.net/articles/copper-pipe-sizes-comprehensive-guide/. By delving into the world of copper pipe fittings, readers will gain valuable insights into creating reliable and durable plumbing systems.

Understanding Copper Pipe Fittings

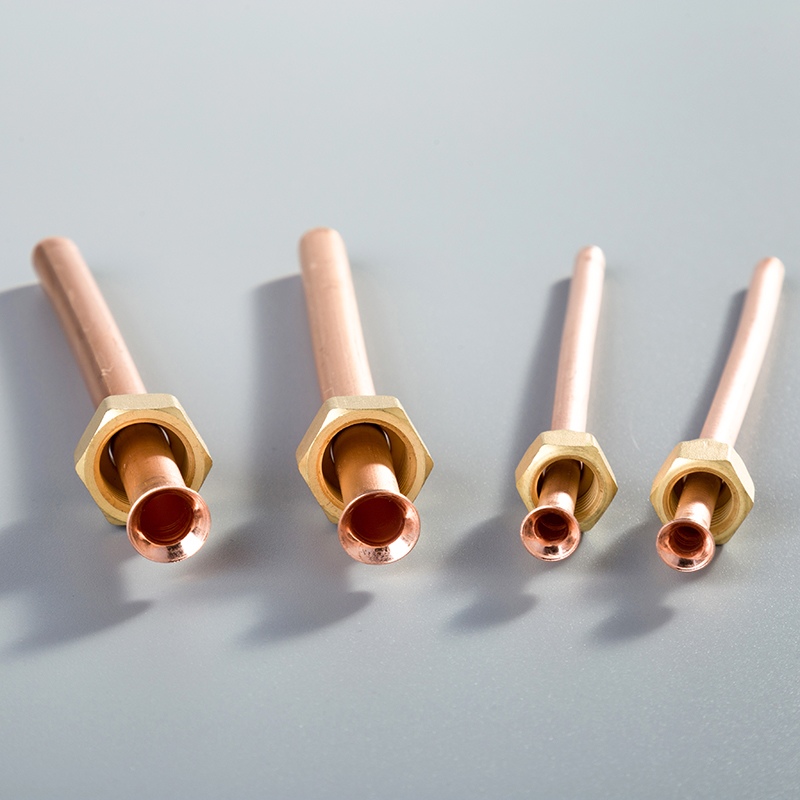

When it comes to plumbing systems, copper pipe fittings are indispensable components that ensure seamless connections and efficient water flow. These fittings offer a diverse range of options, including elbows, tees, couplings, and adapters, each serving a specific function based on the plumbing application at hand.

Elbows play a crucial role in changing the direction of pipes, allowing for smooth transitions around corners or obstacles without disrupting the flow. On the other hand, tees are essential for joining three pipes at a single point, enabling branching into separate lines efficiently. Meanwhile, couplings serve the purpose of connecting two pipes securely, ensuring a leak-free plumbing system. Lastly, adapters come into play when connecting pipes of dissimilar materials, providing versatility in plumbing installations.

Understanding the different types of copper pipe fittings is vital for selecting the right components that align with your specific project requirements. Whether you need to redirect the flow of water or join multiple pipes together seamlessly, having knowledge about these fittings' functions is key to achieving a successful plumbing system.

In addition to comprehending the types of copper pipe fittings available, it is essential to grasp the nuances of copper pipe sizes. This includes understanding nominal sizes, outer diameters, and wall thicknesses to ensure compatibility and optimal performance within your plumbing setup. For detailed insights into copper pipe sizes, you can refer to this comprehensive guide.

By familiarizing yourself with the various types of copper pipe fittings and their respective functions, as well as gaining knowledge about copper pipe sizes and dimensions, you equip yourself with the necessary information to tackle plumbing projects effectively. The right combination of fittings and proper sizing not only ensures a reliable plumbing system but also contributes to its longevity and efficiency.

Tools and Techniques

Soldering Techniques

Cleaning Surfaces

To begin the soldering process effectively, start by cleaning the surfaces of the copper pipes and fittings thoroughly. This step ensures that any dirt, debris, or oxidation is removed, allowing for a secure bond between the materials.

Applying Flux

Once the surfaces are clean, applying flux is essential to facilitate the soldering process. Flux helps prevent oxidation during heating and enables the solder to flow smoothly into the joint. By applying flux to the cleaned surfaces, you ensure a strong and durable connection between the copper pipes and fittings.

Heating the Joint

After cleaning and flux application, heating the joint evenly is crucial for successful soldering. Using a propane torch or a soldering iron, heat the joint until it reaches the appropriate temperature for solder melting. This step ensures that the solder flows uniformly into the connection, creating a tight seal between the pipes and fittings.

Flowing the Solder

Once the joint is heated adequately, introduce the solder to create a seamless bond between the copper pipes and fittings. The melted solder should flow smoothly around the joint, filling any gaps and forming a solid connection. Properly flowing the solder ensures leak-proof joints and enhances the overall integrity of your plumbing system.

Crimping Tools

Types of Crimp Tools

When soldering is not an option or for quick installations, crimp tools offer an alternative method for connecting copper pipes and fittings securely. There are various types of crimp tools available, including manual crimpers and hydraulic crimpers, each designed for different applications based on pipe size and material.

Using Crimp Tools

Utilizing crimp tools involves placing a crimp ring over the end of a pipe before inserting it into a fitting. Once in position, a crimp tool is used to compress the ring onto both components simultaneously, creating a tight seal without requiring heat or solder. This method provides a convenient and efficient way to join copper pipes in situations where traditional soldering may not be feasible.

Measuring and Cutting

Measuring Tools

Accurate measurements are essential when working with copper pipes to ensure precise fits and proper alignment within your plumbing system. Measuring tools such as tape measures or pipe calipers help determine lengths accurately before cutting or installing pipes. By using measuring tools diligently, you can avoid errors in sizing that could lead to leaks or inefficiencies in your plumbing setup.

Cutting Tools

Equally important as measuring is using appropriate cutting tools to trim copper pipes effectively. Pipe cutters or hacksaws are commonly used to make clean cuts on copper pipes without causing damage or deformities. Ensuring straight cuts with sharp cutting tools guarantees seamless connections between pipes and fittings during installation.

Common Issues and Solutions

Preventing Leaks

Proper Soldering

Effective soldering plays a pivotal role in preventing leaks within copper pipe fittings. By ensuring that the surfaces are meticulously cleaned before applying flux, individuals can create a strong bond between the pipes and fittings. Heating the joint evenly is essential to facilitate the solder's seamless flow, guaranteeing a secure connection. This meticulous process of cleaning, flux application, heating, and solder flowing results in leak-proof joints that enhance the overall integrity of the plumbing system.

Using Quality Fittings

Utilizing high-quality copper pipe fittings is paramount in preventing leaks and maintaining a durable plumbing system. By selecting fittings that meet industry standards and specifications, individuals can ensure proper alignment and secure connections between pipes. Quality fittings not only contribute to leak prevention but also enhance the longevity of the plumbing system by withstanding various environmental factors. Investing in superior fittings is an investment in the reliability and efficiency of your plumbing installations.

Addressing Thermal Expansion

Expansion Considerations

When addressing thermal expansion in copper pipe systems, it is crucial to consider the potential impacts on overall system performance. Understanding how copper pipes expand under high temperatures helps individuals anticipate changes in length and adjust their installation accordingly. By factoring in thermal expansion considerations during the design phase, individuals can prevent issues such as pipe misalignment or structural stress, ensuring a robust and resilient plumbing system.

System Design Adjustments

Making necessary adjustments to the system design is essential for accommodating thermal expansion effectively. Implementing expansion loops or offsets in long runs of copper piping allows for natural movement without compromising structural integrity. Additionally, incorporating flexible connectors or joints at strategic points within the system enables pipes to expand and contract freely without causing damage. By proactively adjusting the system design to account for thermal expansion, individuals can mitigate potential risks and maintain optimal performance throughout varying temperature conditions.

Case Studies:

Severe Consequences of Neglecting Thermal Expansion: In several documented cases, failure to address thermal expansion led to significant damage within copper pipe systems.

Impact on Structural Stability: The lack of proper expansion considerations resulted in structural stress on pipes, leading to leaks and inefficiencies.

Industry Insights: Professionals emphasize the importance of integrating thermal expansion solutions into plumbing designs for long-term durability.

Copper plumbing fittings are renowned for their strength, durability, and resistance to corrosion. They ensure leak-proof connections between pipes, making them indispensable in various industries such as manufacturing, water supply systems, and domestic heating applications. Solder ring fittings, with pre-applied solder, offer a convenient solution for DIY enthusiasts seeking efficient installations. By choosing copper pipe fittings, individuals guarantee reliable performance under extreme conditions and seamless joins that match the quality of the entire plumbing system. Embrace the versatility and reliability of copper fittings for your next DIY plumbing project!

See Also

Becoming an Expert in Copper Pipe Fittings: A Detailed Manual

The Definitive Manual for Top-Notch Copper Pipe Fittings

The Complete Handbook on Copper Pipe Varieties and Soldering

The Indispensable Manual for 3-Inch Copper Pipe Fittings

The Comprehensive Manual for Preserving Copper Pipe Performance