Mastering Copper Pipe Soldering

In the realm of plumbing, soldering plays a pivotal role. It is a technique that utilizes heat to fuse metal components together using solder material, ensuring secure connections in water supply systems. Every plumber must possess the skill of how to solder copper pipe, a fundamental aspect of plumbing repairs. Mastering this art enables professionals to create robust joints and watertight seals effortlessly. Additionally, understanding how to cut a copper pipe and how to bend copper pipe are essential skills for any plumber. This blog post aims to guide you through the process step-by-step, emphasizing the significance of precision and technique in achieving impeccable results. Moreover, being aware of the copper pipe scrap price can be beneficial for managing costs effectively.

Understanding the Basics

Soldering is a technique that involves using heat to fuse metal components together with solder material. This process serves the purpose of creating secure connections in various systems, including plumbing.

Definition and Purpose

Soldering is the method of joining metal parts by melting and flowing a filler metal into the joint to form a secure bond.

The primary purpose of soldering is to create a permanent connection between two or more metal components.

Common Applications

Plumbing: Soldering is extensively used in plumbing for connecting copper pipes, ensuring leak-free water supply systems.

Electronics: It is commonly employed in electronics for circuit board assembly, creating reliable electrical connections.

Copper pipes are favored in plumbing for their exceptional properties that make them ideal for various applications.

Advantages of Copper

Durability: Copper pipes have a long lifespan and can withstand high pressure, making them suitable for both residential and commercial plumbing systems.

Corrosion Resistance: Copper is resistant to corrosion, ensuring the integrity of the piping system over time.

Common Uses in Plumbing

Water Supply Lines: Copper pipes are commonly used for transporting potable water due to their cleanliness and safety.

Heating Systems: They are preferred for radiant heating systems as they efficiently conduct heat throughout a space.

Tools and Materials Needed

Essential Tools

To begin soldering copper pipes effectively, the following tools are essential:

Soldering Iron or Torch

A soldering iron or torch is crucial for heating the joint to the required temperature for solder application. The heat from the tool allows the solder to melt and create a strong bond between the copper pipe and fitting.

Pipe Cutter

A pipe cutter is necessary to ensure precise and clean cuts on the copper pipe. Cutting the pipe to the correct length is vital for a secure connection during the soldering process.

Wire Brush

A wire brush plays a significant role in preparing the surface of the copper pipe. It helps in removing any debris or oxidation that could hinder proper adhesion between the pipe and fitting.

Necessary Materials

In addition to the tools mentioned above, specific materials are required for successful copper pipe soldering:

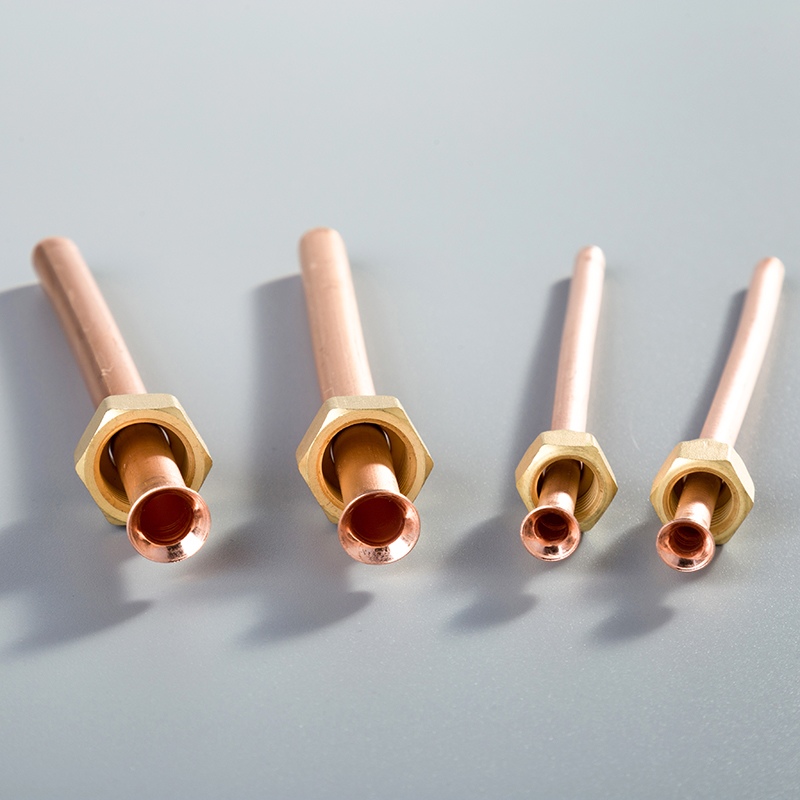

Copper Pipes

Copper pipes are the primary components that need to be joined using solder. Ensuring you have enough length of copper piping for your project is essential before starting the soldering process.

Solder

Solder acts as the bonding agent that creates a watertight seal between copper pipes. Choosing high-quality solder with a suitable melting point is crucial for achieving durable joints.

Flux

Flux is a critical component used in soldering copper pipes. Applying flux around the joint before soldering helps in cleaning and preparing the surface, ensuring proper adhesion between the pipe and fitting.

Preparing for Soldering

Safety Precautions

Protective Gear

Welding gloves and safety glasses are essential when soldering copper pipes to protect your hands and eyes from sparks.

Always keep the flame of the torch at least 12 inches away from the joint and pipe to prevent accidents.

Ventilation

Working in a well-ventilated area is crucial during the soldering process. Proper ventilation helps in dissipating fumes and ensuring a safe working environment.

Preparing the Pipes

Measuring and Cutting

Begin by measuring the copper pipe accurately using a measuring tape.

Use a pipe cutter to make clean and precise cuts on the copper pipe according to the required length for your project.

Cleaning the Pipes

Before soldering, it is imperative to clean the surfaces of the copper pipes thoroughly.

Utilize a wire brush to remove any debris or oxidation that could hinder proper adhesion between the pipe and fitting.

The Soldering Process

Applying Flux

Importance of Flux

Flux is a crucial element in the soldering process as it facilitates the proper adhesion between the copper pipe and fitting.

Ensuring that flux is applied adequately around the joint before soldering is essential for creating a strong and leak-free connection.

Professional plumbers emphasize the significance of flux in achieving durable joints when soldering copper pipes.

How to Apply Flux

Begin by cleaning the surface of the copper pipe thoroughly to remove any debris or oxidation.

Use an acid brush to apply a thin layer of flux evenly around the hole in the copper pipe.

Remember that applying too much flux can be counterproductive, so aim for a uniform and thin coating for optimal results.

Heating the Joint

Using a Soldering Iron

When using a soldering iron, ensure that it reaches the appropriate temperature for melting the solder effectively.

Gently heat the joint with the soldering iron, moving it in circular motions to distribute heat evenly.

Properly heating the joint is crucial for allowing capillary action to draw in the molten solder and create a secure bond.

Using a Torch

If using a torch, maintain a safe distance from flammable materials while heating the joint.

Directly heat the fitting rather than focusing on the copper tube to achieve optimal results.

Professional plumbers recommend using a torch with adjustable flame settings for precise control during soldering.

Applying the Solder

Techniques for Even Application

Start by holding the solder wire against one side of the joint where it meets both components.

Allow the heated joint to draw in and melt solder, ensuring it flows smoothly around both surfaces.

Move along the seam, maintaining steady pressure on the solder wire for consistent application.

Ensuring a Strong Joint

Verify that there is enough solder applied to fill all gaps between components without excess buildup.

Inspect visually to confirm that solder has flowed completely around both surfaces, indicating proper adhesion.

A well-executed soldering process results in a robust joint that guarantees long-lasting performance.

Post-Soldering Steps

After completing the soldering process for copper pipes, it is crucial to follow specific post-soldering steps to ensure the integrity and functionality of the joint. These steps involve cooling and cleaning the soldered area and inspecting the joint for any potential issues.

Cooling and Cleaning

Allowing the Joint to Cool

Letting the soldered joint cool naturally is essential to prevent any premature disturbances that could compromise the bond. During this cooling period, avoid any excessive movement or handling of the recently soldered area to maintain its structural integrity.

Remember that allowing sufficient time for the joint to cool ensures a solid and durable connection between the copper pipe and fitting. This patience in cooling contributes significantly to the overall strength of the soldered joint.

Cleaning Excess Flux

Once the joint has cooled adequately, it is necessary to clean off any excess flux residue that may be present on the surface. Using a clean cloth or brush, gently remove any leftover flux to enhance the appearance of the soldered joint.

Properly cleaning excess flux not only improves the aesthetics of your plumbing work but also prevents potential blockages or obstructions within your piping system. This meticulous attention to detail in cleaning ensures optimal performance from your soldered joints.

Inspecting the Joint

Checking for Leaks

Conduct a thorough inspection of the soldered joint by visually examining it for any signs of leaks or seepage. Look closely at all connection points and seams to detect even minor leaks that could lead to significant issues over time.

A leak-free joint is essential for maintaining a reliable water supply system, so addressing any leaks promptly is crucial. By checking diligently for leaks after soldering, you can identify and resolve potential problems before they escalate.

Ensuring a Secure Connection

Verify that the soldered joint exhibits a secure connection between the copper pipe and fitting without any gaps or loose components. Gently test the stability of the joint by applying slight pressure to ensure its structural integrity.

Ensuring a secure connection guarantees long-term performance and prevents future complications such as leaks or bursts in your plumbing system. By confirming a robust bond between components, you can trust in the durability of your soldered joints.

Balkan Training Program emphasizes the importance of practice and patience in mastering the art of soldering copper pipes. With dedication and safe techniques, anyone can achieve professional results. Remember, learning to solder is a valuable skill that opens doors to various opportunities. Take advantage of expert guidance and real-world training to enhance your abilities. Start your journey towards becoming a proficient copper pipe solderer today!

See Also

Become a Copper Pipe Soldering Expert in Your Home

Soldering Mastery: Simple Tricks for 1 1/2 Copper Pipes

Expertise in Copper Pipe Fittings: The Complete Manual

Easy Guide: Soldering a Copper Pipe for Novices

The Definitive Manual on Copper Pipe Varieties and Soldering