Mastering Quality Control in Copper Pipe Coils: A Detailed Analysis

Quality control in copper pipe coils is paramount to ensuring product reliability and safety. This blog will write a detailed analysis on the quality control procedures in modern 1/4 3/8 twin copper pipe coils. By exploring the importance of stringent quality measures, readers will gain insights into how automated methods and structural assessments play a crucial role in enhancing product integrity. Ultimately, this analysis aims to highlight how quality control procedures are indispensable for maintaining high standards in the industry.

The Importance of Quality Control

In the realm of modern 1/4 3/8 twin copper pipe coils, ensuring reliability is a fundamental aspect that cannot be overlooked. Automated methods play a pivotal role in maintaining the integrity and consistency of the product. By leveraging automated processes, companies can streamline their operations and minimize human error. Structural assessments further reinforce the reliability factor by identifying any potential weaknesses or defects in the coils.

When it comes to safety standards, compliance with regulations is non-negotiable. Companies must adhere strictly to industry guidelines and governmental requirements to ensure the safety of both workers and end-users. Preventing failures is another critical aspect of safety standards. By implementing robust quality control measures, companies can proactively identify and rectify any issues before they escalate into major failures.

Production efficiency is a key driver for success in the manufacturing industry. Minimizing waste not only contributes to cost savings but also aligns with sustainable practices. Enhancing productivity goes hand in hand with minimizing waste; by optimizing processes and workflows, companies can maximize output without compromising on quality.

Expert Testimony:

DBS&A Experts

DBS&A staff members have provided expert opinions and testimony in both state and federal court to resolve a wide range of environmental characterization, monitoring, and remediation problems.

Yaang Experts

Practice has proved that manual tungsten arc welding is prone to and the most harmful problem is welding cracks; then is the porosity and not welded through, there is a higher preheating temperature, the material is easy to carburization and embrittlement and other deficiencies.

JSPubs Experts

Particular expertise in the thermal degradation of austenitic stainless steels and nickel-based alloys

Quality Control Procedures

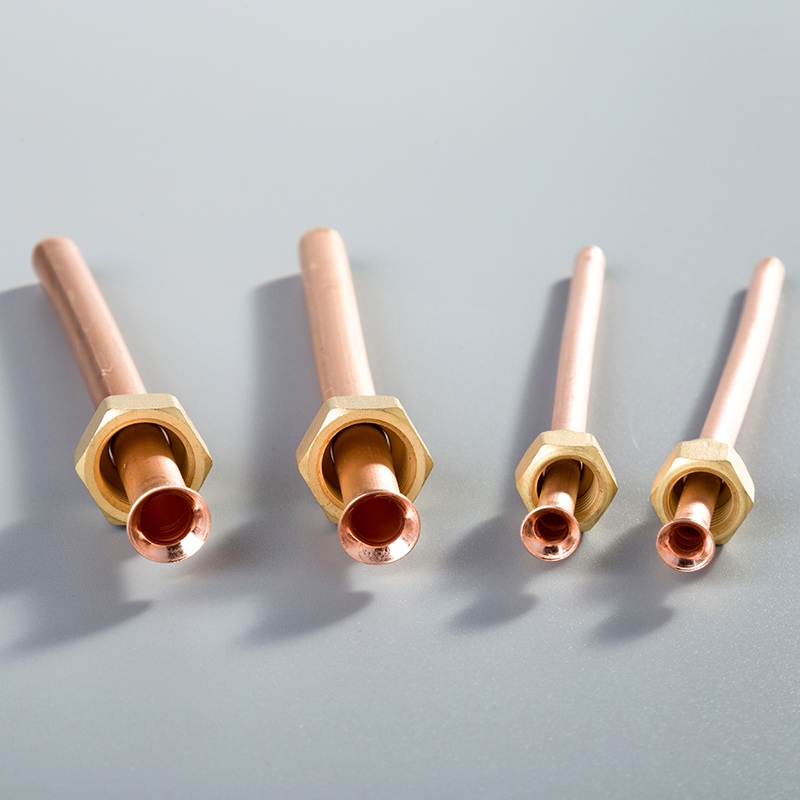

Material Selection

When considering the material selection for modern 1/4 3/8 twin copper pipe coils, Refrigeration Quality Copper Tubes are a crucial component. These tubes are specifically designed to withstand varying temperatures and pressures, ensuring optimal performance in refrigeration systems. Additionally, Soft Drawn Seamless Tubes play a vital role in enhancing the flexibility and durability of the coils. Their seamless construction minimizes the risk of leaks or structural weaknesses, guaranteeing a reliable end product.

Manufacturing Processes

In the realm of manufacturing processes for copper pipe coils, Automated Methods have revolutionized production efficiency and quality control. By automating certain tasks, companies can reduce human error and ensure consistency in their products. Welding in evaporators is another critical step in the manufacturing process. This intricate procedure demands precision and expertise to create strong and durable joints within the coils.

Inspection and Testing

Quality control procedures for modern 1/4 3/8 twin copper pipe coils involve meticulous inspection and testing methods. Resistance and Aperture Current Control are essential techniques used to evaluate the electrical conductivity and integrity of the coils. Through these tests, manufacturers can identify any irregularities or defects that may compromise the overall quality of the product. Furthermore, conducting a Detailed Engineering Analysis allows for a comprehensive assessment of the structural integrity and performance capabilities of the coils.

The integration of these quality control procedures ensures that modern 1/4 3/8 twin copper pipe coils meet stringent industry standards while delivering reliable and safe products to consumers.

Future Directions

Technological Advancements

Innovations in automation are reshaping the landscape of quality control procedures for modern 1/4 3/8 twin copper pipe coils. Companies are increasingly integrating cutting-edge technologies to streamline their processes and enhance efficiency. By leveraging automated systems, manufacturers can achieve higher levels of precision and consistency in their products. The implementation of robotics and AI-driven solutions has revolutionized the production line, allowing for real-time monitoring and immediate adjustments to optimize quality control measures.

Enhanced monitoring systems have become indispensable tools in ensuring the reliability and safety of copper pipe coils. These advanced systems offer comprehensive insights into every stage of the manufacturing process, from material selection to final inspection. By utilizing sensors and data analytics, companies can proactively identify potential issues and address them before they impact product quality. Real-time monitoring enables quick decision-making, leading to improved overall performance and customer satisfaction.

Industry Trends

Sustainability practices are at the forefront of industry trends shaping the future of modern 1/4 3/8 twin copper pipe coils. As environmental concerns continue to drive change across sectors, manufacturers are embracing eco-friendly initiatives to reduce their carbon footprint. From recycling materials to optimizing energy consumption, sustainability practices not only benefit the environment but also contribute to cost savings in the long run. By adopting green technologies and processes, companies can align with global sustainability goals while maintaining high-quality standards.

Global standards play a pivotal role in ensuring consistency and interoperability within the industry. As markets become increasingly interconnected, adhering to international regulations and norms is essential for facilitating trade and collaboration on a global scale. By complying with established standards, manufacturers can demonstrate their commitment to quality control excellence while gaining a competitive edge in diverse markets worldwide.

Ensuring the quality of thick-walled copper pipe fittings field welding is a key factor.

Accumulated experience for high-quality welding of copper pipe fittings and improved repair qualification rate.

See Also

Exploring Copper Pipe Fittings: An In-Depth Manual

The Definitive Handbook on Contemporary Copper Pipe Coils

Revealing the Affordability of Double Copper Pipe Coils