Pro Tips for Accurate Copper Pipe Measurement

Write a 'Tips' blog post on 'Tips for accurate measurement of copper pipes'

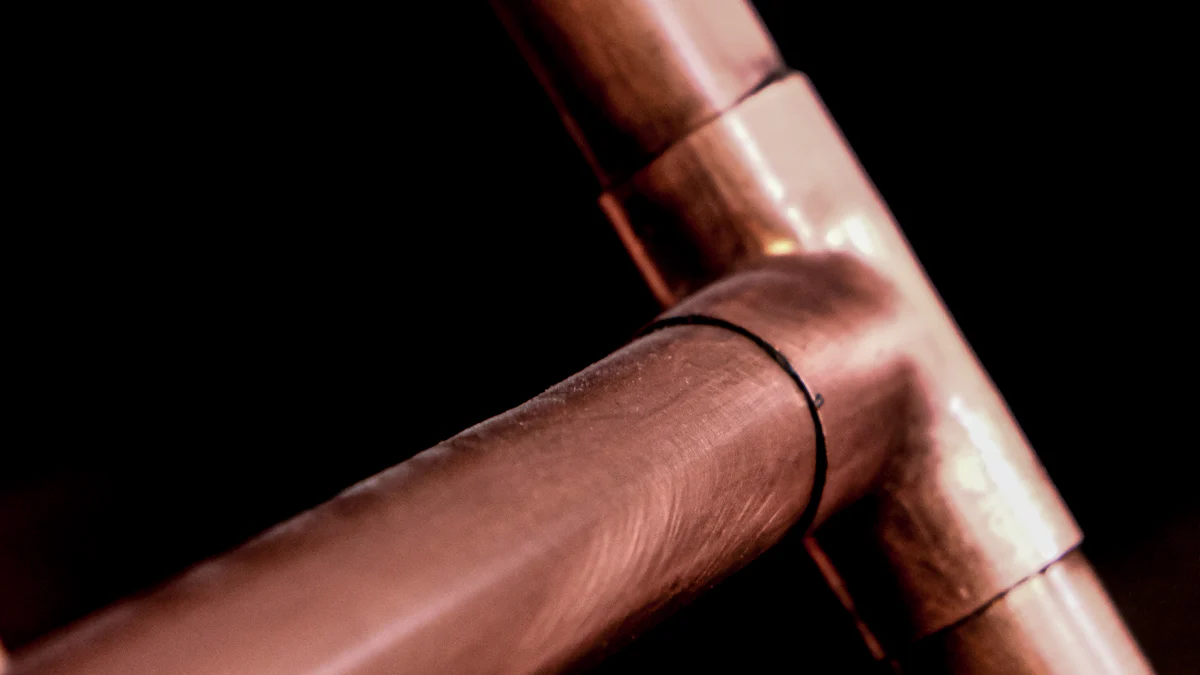

To achieve precise fittings and seamless alignments, accurate measurement of copper pipes is paramount. Understanding the significance of maintaining consistency throughout the process is key to verifying initial calculations and identifying discrepancies promptly. Professionals in the plumbing industry emphasize the use of tools like calipers for precise measurements, ensuring a firm grip for accurate readings. By utilizing simple yet reliable techniques such as measuring tape and rulers, individuals can calculate the diameter effectively. Let's delve into essential tips and techniques that guarantee optimal results when measuring copper pipes.

Essential Tools for Measurement

When it comes to accurately measuring copper pipes, having the right tools at your disposal is crucial. Measuring Tape is a fundamental tool that provides flexibility and ease of use in various scenarios. By understanding How to Use Measuring Tape, individuals can ensure precise measurements every time. The Benefits of Measuring Tape include its portability and versatility, making it a go-to tool for quick measurements on the job.

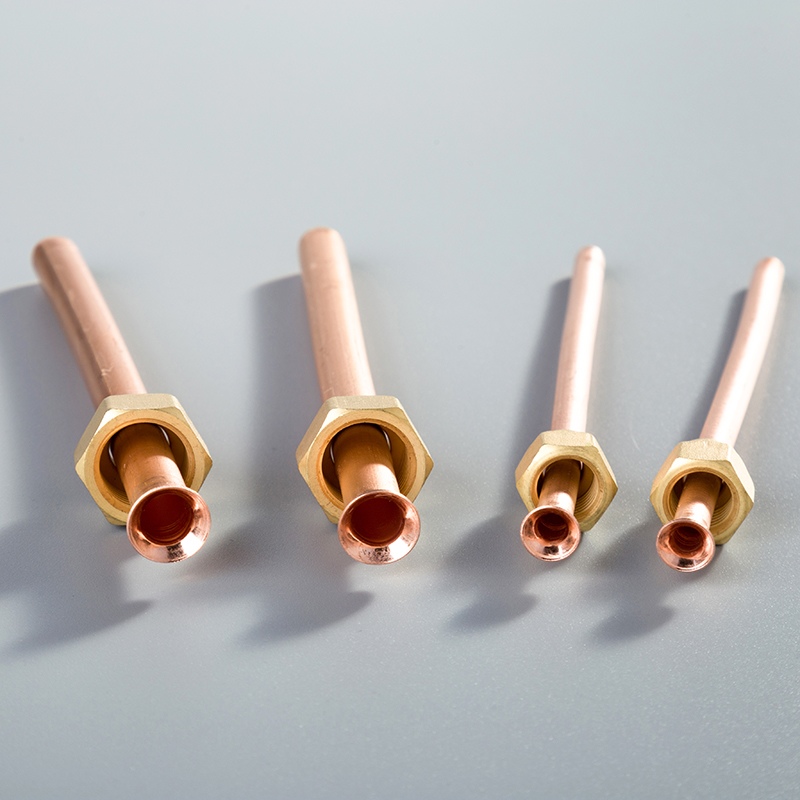

Calipers are another indispensable tool for professionals seeking accuracy in their measurements. Learning How to Use Calipers effectively can significantly enhance the precision of your readings. The Benefits of Calipers lie in their ability to provide exact measurements with a firm grip, ensuring reliable results when measuring copper pipes.

For those looking to elevate their measurement game, Digital Calipers offer advanced features and unparalleled accuracy. Mastering How to Use Digital Calipers allows for seamless transitions between different units of measurement, catering to specific project requirements. The Benefits of Digital Calipers include high precision levels and user-friendly interfaces, making them ideal for intricate measurements in plumbing projects.

By incorporating these essential tools into your workflow, you can streamline the measurement process and achieve optimal results when working with copper pipes.

Techniques for Accurate Measurement

When measuring copper pipes, precision is paramount to ensure seamless fittings and reliable installations. Utilizing the String Method for measuring the circumference of a pipe is a practical approach that guarantees accurate results. By wrapping a string around the pipe and then measuring the length of the string, individuals can obtain an initial measurement that serves as the basis for further calculations. Calculating the Diameter from this circumference measurement involves dividing it by 3.1416, providing an exact outer diameter (OD) value crucial for precise fittings.

For scenarios where accessing the open end of the pipe is challenging, Using Calipers for Precision becomes essential. Calipers offer advanced measurement capabilities, allowing professionals to obtain accurate readings even in confined spaces. The ability to grip firmly and provide exact measurements makes calipers indispensable tools in plumbing projects. Ensuring Consistency throughout the measurement process is equally vital to validate initial calculations and identify any discrepancies promptly.

In a recent study on digital caliper accuracy testing, it was proven that these tools offer precise measurements with resolutions as fine as 0.0005"/0.01mm/1/128". This level of accuracy is invaluable when working with copper pipes that require meticulous measurements for optimal fittings and alignments. Additionally, experts emphasize the importance of calipers for achieving accurate readings in various applications, highlighting their role in enhancing measurement precision.

By incorporating these techniques into your workflow and leveraging advanced tools like digital calipers or traditional methods such as using strings and calipers, you can elevate your measurement capabilities significantly. Consistency and precision are key elements that contribute to successful plumbing projects, ensuring that every fitting aligns seamlessly for long-lasting results.

Best Practices for Measurement

Consistency in Measurement

Prioritize maintaining consistency throughout the measurement process to ensure accurate results. By adhering to consistent practices, professionals can validate initial calculations effectively. Consistency leads to precise measurements, which are essential for successful plumbing projects. To maintain consistency, gather necessary tools like calipers for accurate measurements. Using calipers ensures reliable and uniform readings, contributing to the overall accuracy of the project.

Importance of Consistency

In industries where precision and efficiency are paramount, accurate information is crucial. Precise measurements of copper pipe weight are essential for successful project planning and execution. Professionals recognize that consistency in measurements is a cornerstone of quality workmanship. By prioritizing consistency, individuals can verify their calculations and identify any discrepancies promptly.

Tips for Maintaining Consistency

Utilize tools like digital calipers with high accuracy levels to ensure consistent measurements.

Regularly calibrate your measuring instruments to maintain precision.

Document your measurement processes to track any variations and ensure consistency over time.

Accuracy in Measurement

Emphasize the importance of accuracy when measuring copper pipes to achieve optimal fittings and alignments. Accurate measurements are fundamental for ensuring seamless installations and long-lasting results. The digital caliper provides high accuracy of measurements, with an achievable precision level of +/- 0.02 mm | 0.001".

Importance of Accuracy

Accurate measurements play a vital role in the success of plumbing projects. Precision in measuring copper pipes is crucial for determining appropriate fittings and ensuring leak-free connections. Professionals rely on accurate measurements to guarantee the structural integrity and functionality of plumbing systems.

Tips for Ensuring Accuracy

Double-check all measurements before making cuts or installations.

Use marking tools like rulers or pencils to indicate precise cutting points.

Verify the dimensions provided by manufacturers against your own measurements for accuracy validation.

Accurate measurement stands as the cornerstone of successful plumbing projects, ensuring precise fittings and preventing costly errors. Understanding the dimensions of copper tubing is vital for informed decision-making in industrial applications. REXBETI's all stainless steel digital caliper enhances measurement reliability, making tasks more accurate. By prioritizing precision and utilizing high-quality tools, professionals can achieve optimal results in their projects. Remember, every precise measurement contributes to the overall success of your plumbing endeavors.

See Also

Simple Steps: Measuring Copper Pipe for Professional Results

Quick Guide: Measuring Copper Pipes for DIY Achievement

Effortless Guide: Measuring Copper Pipes Like an Expert