How to Properly Use a Copper Pipe Crimper

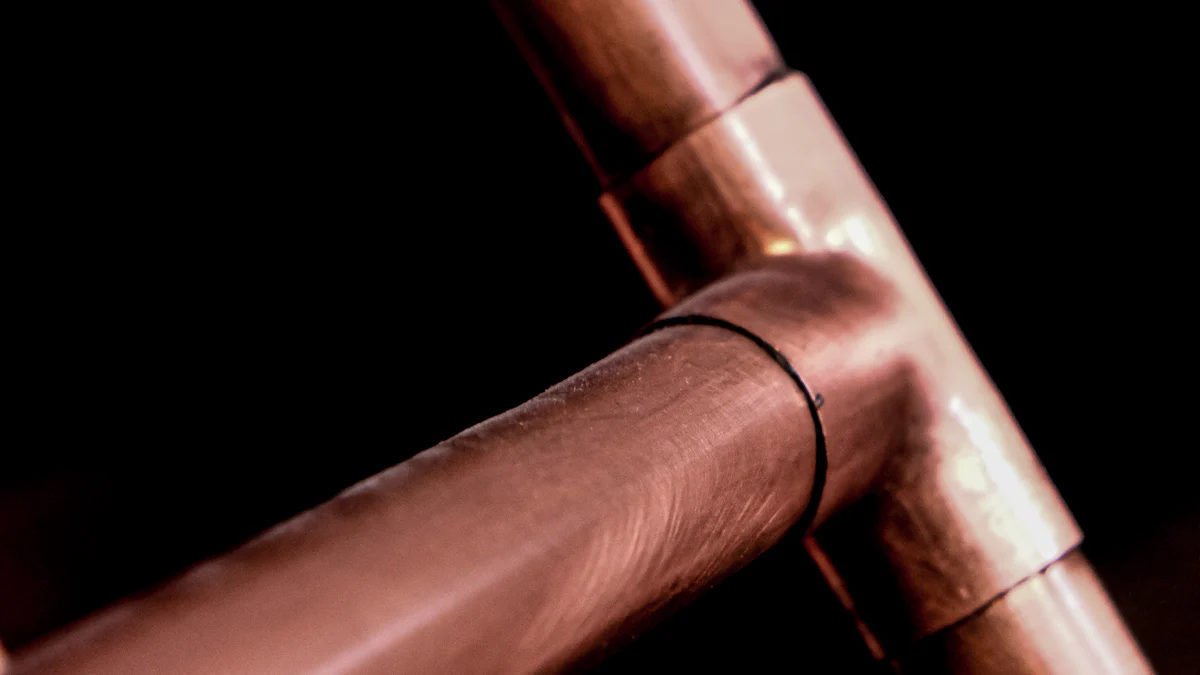

When it comes to plumbing tasks, using a copper pipe crimper is essential for creating secure connections. The copper pipe crimper plays a crucial role in ensuring leak-free seals in copper piping systems. Alongside the copper pipe crimper, having the right tools like copper pipe cutters and copper pipe insulation is vital for a comprehensive approach to plumbing. Unlike soldering, crimping offers numerous advantages that make it a preferred method among professionals. This blog will delve into the significance of utilizing a copper pipe crimper, highlight the benefits over traditional soldering techniques, and provide an overview of the step-by-step process for efficient copper pipe repair practices.

Tools and Materials

Essential Tools

Copper pipe crimper

When it comes to creating secure connections in copper piping systems, a copper pipe crimper is an indispensable tool. The copper pipe crimper utilizes pressure to connect wires or components, ensuring a reliable and leak-free seal. This method of crimping is preferred for its flexibility, heat resistance, and vibration resistance compared to soldering techniques.

Copper pipe cutters

In addition to the copper pipe crimper, having copper pipe cutters is essential for precise and accurate cuts in copper pipes. Properly cutting the pipes ensures a clean edge for seamless fittings and joints. Using the right tools like copper pipe cutters guarantees a standard procedure for maintenance tasks, making it ideal for various plumbing applications.

Copper pipe insulation

To enhance the efficiency of your plumbing system, consider using copper pipe insulation. Insulating copper pipes helps prevent heat loss and minimizes condensation, ultimately improving energy efficiency. By incorporating copper pipe insulation, you can maintain consistent temperatures within your piping system while reducing energy costs.

Necessary Materials

Copper pipes

When working on plumbing projects, having high-quality copper pipes is crucial for durability and longevity. Copper pipes are known for their corrosion resistance and reliability, making them a popular choice in residential and commercial plumbing systems.

Press fittings

For secure connections between pipes and fittings, utilize press fittings along with your copper pipe crimper. Press fittings ensure tight seals without the need for soldering or welding, simplifying the installation process while maintaining structural integrity.

Measuring tape

A fundamental tool in any plumbing toolkit is a reliable measuring tape. Accurate measurements are essential when cutting copper pipes and determining fitting placements. With a measuring tape, you can ensure precision in your installations, resulting in professional-looking and functional plumbing systems.

Preparation Steps

Measuring and Cutting

To ensure precise fittings in your plumbing project, measuring the copper pipe accurately is crucial. This step guarantees that the pipe will fit perfectly into the desired space without any unnecessary bends or gaps. By using a measuring tape, you can determine the exact length required for the pipe, allowing for a seamless installation process.

When it comes to cutting the pipe, using copper pipe cutters is essential for achieving clean and smooth edges. These specialized tools provide a straight cut, ensuring that the pipe ends are even and free from any deformities. Properly cutting the copper pipe not only facilitates easier fitting but also prevents any leaks or irregularities in the connection.

Marking and Fitting

Before proceeding with the crimping process, it is important to mark the depth of the joint on both the pipe and fitting. This marking ensures that you apply the correct amount of pressure during crimping, resulting in a secure and leak-free connection. By marking both components, you can easily align them for a precise fit without any guesswork.

Once you have marked the joint depth, it's time to install the correct jaw on the press tool. Choosing the appropriate jaw size ensures that the crimping tool fits snugly around the fitting without causing any damage. Proper installation of the jaw guarantees a successful crimping process and prevents any potential issues with sealing or alignment.

Remember, accurate measurements and proper cutting techniques are fundamental in preparing your copper pipes for crimping. By following these preparation steps diligently, you can create reliable connections that withstand high pressures and ensure long-lasting performance in your plumbing system.

Crimping Process

Positioning the Tool

Position the tool on the fitting

To initiate the crimping process, position the copper pipe crimper securely on the fitting. Ensuring a stable placement of the tool is essential for creating a tight and reliable connection between the pipe and fitting. By aligning the crimper correctly with the fitting, you set the stage for a successful crimp that guarantees leak-free performance.

Ensure proper alignment

Verify that the tool is aligned accurately with the fitting before applying pressure. Proper alignment prevents any potential misalignments or deformities in the crimped joint, ensuring a secure and durable connection. By double-checking the alignment, you can guarantee that the crimping process proceeds smoothly without any complications.

Applying Pressure

Press the fitting

Once you have positioned the tool correctly, proceed to press firmly on the fitting using the copper pipe crimper. Applying consistent pressure ensures that the crimp ring compresses evenly around both components, creating a strong and watertight seal. The pressing action forms a secure connection that can withstand high pressures and temperature variations, making it an ideal choice for plumbing applications.

Inspect the crimped joint

After pressing the fitting, inspect the crimped joint to confirm its integrity and reliability. A thorough inspection allows you to identify any irregularities or imperfections in the connection that may compromise its effectiveness. By examining the crimped joint closely, you can ensure that it meets industry standards for quality and performance, providing peace of mind regarding its long-term durability.

Crimping with precision and attention to detail is crucial for achieving robust connections in your plumbing projects. By following these steps diligently and focusing on proper positioning and pressure application, you can create leak-free seals that enhance your plumbing system's efficiency and reliability.

To summarize, the crimping process involves precise positioning and applying pressure to create secure connections in plumbing projects.

The reliability of crimped connections surpasses traditional methods, ensuring leak-free seals that withstand high pressures and temperature changes.

Embrace the efficiency of using a copper pipe crimper for your plumbing needs, guaranteeing durable and long-lasting results.

See Also

Top 5 Tips for Utilizing 1/4 Copper Pipe Fittings

Selecting the Top Copper Pipe Flaring Tool for 1/2 Pipe

Quick Guide: Attaching Compression Fittings on Curved Copper Pipes

Basic Guide: Soldering a Copper Pipe for Novices

DIY Made Simple: Installing Copper Pipe Coils Professionally