What Are Refrigeration Copper Pipes and How Are They Used in Air Conditioning

Copper pipes, particularly refrigeration copper pipe, are important in air conditioners. They move refrigerants between parts like compressors, condensers, and evaporators. These pipes are very strong and last a long time. Special coatings protect them from rust, making them great for cooling systems. New designs use thinner refrigeration copper pipes to save energy. Smaller pipes lower the space needed by 57% and reduce tube volume by 41%. These pipes save space, use less energy, and cost less to run. They are essential for today’s air conditioning systems.

Key Takeaways

Copper pipes are important for air conditioners. They move refrigerants.

Picking the right pipe type (K, L, or M) is key. It depends on how much pressure the system needs.

Insulated pipes save energy by stopping heat loss and moisture. This helps lower energy costs.

Flexible pipes are easy to install in small spaces. They save time and need fewer extra parts.

Copper pipes last long and resist rust. They need less care than other materials.

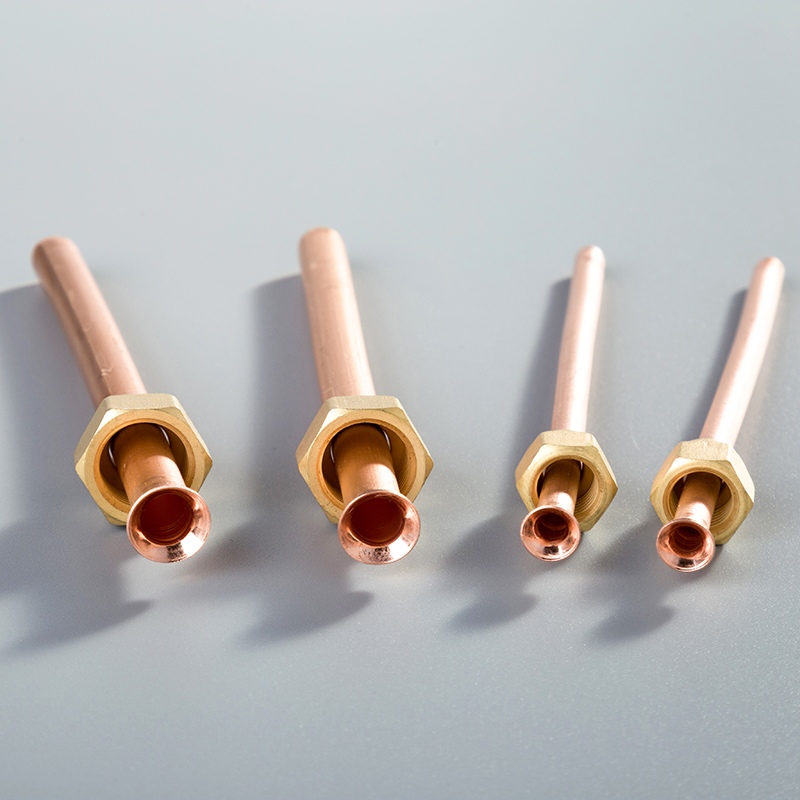

Types of Refrigeration Copper Pipes

Refrigeration copper pipes come in different types. Each type is made for specific air conditioning needs. Knowing these types helps you pick the right one.

Type K, Type L, and Type M Copper Pipes

There are three main types of copper pipes: K, L, and M. They differ in thickness, pressure strength, and uses. The table below shows their features:

Type | Wall Thickness | Pressure Rating | Uses |

|---|---|---|---|

K | Thickest | Highest | High-pressure, underground, HVAC systems |

L | Medium | Moderate | Home plumbing, fire safety, HVAC systems |

M | Thinnest | Lowest | Indoor repairs, home extensions |

Type K pipes are the strongest with thick walls. They work well for high-pressure jobs and underground use. Type L pipes are strong but cheaper, good for homes and businesses. Type M pipes are thin and cost less, best for indoor, low-pressure tasks.

Think about your system's pressure needs when choosing a pipe. These pipes are often used in plumbing but may not handle high refrigeration pressures. Picking the right type keeps your system safe and efficient.

Capillary Tubes and Coiled Copper Tubes

Capillary and coiled copper tubes are key in air conditioners. Capillary tubes lower refrigerant pressure and temperature to cool air. They work well with eco-friendly refrigerants like R600a.

Studies show tube shape affects performance. Coiled tubes cool better, while straight tubes allow more refrigerant flow. Coiled tubes are great for improving refrigerant movement in systems.

Refrigerants flow through capillary tubes in a complex way. Pressure drops cause boiling, creating two-phase flows. This process cools air efficiently, making capillary tubes vital for refrigeration.

Insulated Copper Pipes

Insulated copper pipes keep air conditioners working well. Insulation stops water from forming on pipes, avoiding damage and poor performance. It also keeps refrigerant at the right temperature for better cooling.

Insulated pipes save energy by reducing heat loss. This lowers bills and protects pipes from rust and damage, making systems last longer.

Using insulated pipes improves energy use and keeps temperatures steady. They are a smart choice for modern air conditioners.

Flexible Copper Pipes

Flexible copper pipes are handy and adaptable for air conditioning. They can bend easily, fitting into tight or awkward spaces. This makes installation simpler and reduces the need for extra fittings.

Tip: Use flexible copper pipes in places where rigid pipes won't fit.

Advantages of Flexible Copper Pipes

Flexible copper pipes have many benefits over rigid ones. The table below shows how they compare:

Feature | Flexible Copper Pipes | Rigid Copper Pipes |

|---|---|---|

Installation Ease | Simple to install, bends easily, fewer parts needed | Needs precise cutting and more fittings |

Time Efficiency | Faster to set up | Takes longer to install |

Versatility | Works in many situations | Mainly for plumbing and HVAC systems |

Durability | Strong and resists rust | Strong but less flexible |

Maintenance | Needs little upkeep | May need more care |

Flexible copper pipes save time because they need fewer fittings. Their ability to bend helps avoid obstacles without affecting performance. This makes them a top choice for homes and businesses.

Applications of Flexible Copper Pipes

Flexible copper pipes work well in different air conditioning setups. They are great for split systems, linking indoor and outdoor units. Their flexibility ensures smooth connections, even in tricky layouts. They are also ideal for upgrading older systems, as they fit with existing parts.

Why Choose Flexible Copper Pipes?

Flexible copper pipes are both strong and easy to use. They resist rust, helping your air conditioning last longer. With low maintenance, they stay reliable for years. Choosing these pipes improves your system's performance and dependability.

Note: Always check that flexible copper pipes match your system's pressure and refrigerant needs.

Flexible copper pipes are a smart pick for modern air conditioning. They are easy to use, adaptable, and long-lasting. By knowing their advantages, you can make better choices and boost your cooling system's efficiency.

Benefits of Refrigerant Copper Pipes in Air Conditioning Systems

Durability and Longevity

Copper pipes are very strong and last a long time. They can handle high pressure and heat without breaking or bending. This makes them a dependable choice for air conditioning systems.

Studies show copper pipes are used in 70% of HVAC systems worldwide. They are trusted because they work well and cost less to maintain. Copper pipes need 62% less upkeep than PEX pipes, saving money over time. Their smooth insides also lower energy use by 12-18%, improving efficiency.

Evidence Type | Description |

|---|---|

Market Demand | Copper pipes are used in 70% of HVAC systems globally. |

Maintenance Cost | Copper pipes need 62% less maintenance than PEX pipes. |

Energy Efficiency | Smooth inner walls reduce energy use by 12-18%. |

Choosing copper pipes means fewer replacements and lower costs. They keep air conditioning systems running smoothly for years.

Corrosion Resistance

Copper pipes naturally resist rust, making them great for air conditioning systems. Unlike other materials, copper stays strong even when exposed to water or chemicals. This helps prevent leaks and keeps systems working well.

Insulated copper pipes add extra protection. Insulation stops water from forming on pipes, reducing rust and damage. This is especially helpful in humid places where rust is more likely. Using insulated pipes makes your system last longer.

Tip: Check your copper pipes often to ensure insulation is intact. This simple step avoids costly repairs and keeps your system efficient.

Copper's ability to resist rust makes it a smart choice for air conditioning systems, especially in tough environments.

Energy Efficiency and Heat Transfer

Copper pipes are excellent at saving energy and transferring heat. They move heat quickly, helping refrigerants cool air effectively. This is important for systems with multiple cooling zones.

Research shows copper pipes work well in different conditions. Low vibrations reduce heat resistance, while high acceleration improves performance. These features make copper pipes reliable for various needs.

Condition | Measured Improvement in Energy Efficiency/Heat Transfer Properties |

|---|---|

Low-frequency vibrations (0-30 Hz) | Reduced heat resistance in vertical positions |

Longitudinal vibrations | Lower heat transport limits |

High acceleration (3 g) | Better heat pipe performance in certain positions |

High acceleration (6 g and above) | Large temperature changes in evaporators |

Copper pipes also save energy by stopping heat loss during refrigerant movement. This lowers energy bills and helps the environment, making copper a sustainable option.

Note: Pick copper pipes that match your system's refrigerant type and pressure needs for best results.

Using copper pipes improves cooling, saves money, and reduces environmental impact. They are a great choice for efficient air conditioning systems.

Recyclability and Environmental Benefits

Copper pipes are great for the environment and very sustainable. They can be recycled endlessly without losing quality, saving resources. Using copper reduces mining, which harms nature and uses up limited materials.

Recycling copper also cuts down harmful gases. By recycling instead of mining, you help:

Lower carbon dioxide emissions by 65%.

Reduce sulphur dioxide emissions by 85%.

These changes fight climate change and improve air quality. Recycled copper supports a circular economy, where materials are reused instead of thrown away. This reduces waste and helps the planet.

Choosing copper pipes improves your air conditioning system and helps the environment. It’s a smart choice for both performance and sustainability.

Compatibility with Modern Refrigerants

Copper pipes work well with today’s eco-friendly refrigerants. They are made to fit modern air conditioning systems that follow strict environmental rules.

Feature | Description |

|---|---|

Compatibility | Works with new refrigerant systems |

Pipe Type | Flexible copper tubes and cooling parts |

Application | Fits top VRF air conditioning systems |

Small copper pipes have many benefits. Some have special grooves inside to improve refrigerant flow and cooling. This design makes systems smaller, lighter, and easier to install.

Copper pipes also handle eco-friendly refrigerants like R32 and R410A. These need materials that can manage high pressure and heat. Copper’s strength and ability to transfer heat make it perfect for this job.

Using copper pipes keeps your system efficient and eco-friendly. They are a smart choice for homes and businesses, ready for the future.

Installation Methods for Copper Pipes in Air Conditioning

Welding and Brazing Techniques

Welding and brazing join copper pipes securely in air conditioners. Brazing heats the pipe and adds a filler, like silver foil, to seal joints tightly. Controlled heating ensures accuracy during this process. It works well for high-pressure systems and modern refrigerants.

Tests like ultrasonic scans check if brazed joints are strong. These tests find flaws and ensure joints handle stress well. For best results, destructive testing helps set proper brazing rules. This ensures safety standards are followed carefully.

Flaring and Compression Fittings

Flaring and compression fittings are easier ways to connect copper pipes. Flaring shapes the pipe end into a cone to fit snugly. Compression fittings use a nut and ring to hold the pipe. These methods are quick but need regular checks to stop leaks.

Soldering, also called sweating, makes stronger connections. The bond from soldering handles stress and heat changes better than compression fittings. For lasting results with less upkeep, soldering is the better choice.

Fire-Free Mechanical Fittings

Fire-free fittings are great where flames can’t be used. These fittings use push-fit or press-fit systems to join copper pipes without heat. They are perfect for places with strict safety rules.

Copper is easy to work with, making mechanical fittings affordable. Studies show copper cuts installation costs by 25%. Its low maintenance ensures years of reliable use, making it a smart pick for air conditioners.

Tip: Use fire-free fittings in sensitive places like hospitals or schools for safer installations.

Precautions and Best Practices

When setting up copper pipes for air conditioners, safety matters. Work in a space with fresh air to avoid harmful fumes. Wear gloves and safety glasses to protect your hands and eyes. Always turn off the gas supply before starting to prevent accidents. Keep a fire extinguisher close, especially near flammable items.

Measure the pipe length carefully and mark it clearly. Use a pipe cutter or hacksaw to cut the pipe straight and clean. Smooth out sharp edges with a deburring tool to avoid damage. This step helps fittings connect securely.

Follow standards like ASTM B88 to ensure pipes meet quality rules. Check local laws for extra guidelines, especially for gas lines. This keeps your work safe and legal.

Keep your workspace tidy to avoid dust and debris. Messy areas can cause leaks or lower system performance. Inspect tools often to make sure they work properly. Broken tools can affect the quality of your work.

By following these tips, your air conditioner will last longer and work better. These precautions keep you safe and help the system run smoothly for years.

Factors to Consider When Choosing Copper Pipes for Air Conditioning Systems

System Needs and Refrigerant Type

Picking the right copper pipes depends on your system's needs. Different refrigerants need pipes that handle specific pressures and heat. For example, modern refrigerants like R410A and R32 work at higher pressures. This makes strong copper pipes very important.

The pipe's material, design, and condition also affect how well it works. The table below shows key things to check:

Factor | Description |

|---|---|

Pipe Material | The type of material, like copper or plastic, affects performance. |

Installation Design | Good design and proper setup make pipes last longer. |

Water Quality | Poor water quality can damage pipes over time. |

Age of Pipe | Older pipes are more likely to leak or fail. |

Choosing the right material and design for your refrigerant helps your system work better and last longer.

Environmental Effects and Corrosion Risks

The environment can impact how long copper pipes last. High humidity, water quality, and chemicals can cause pipes to fail early. Studies show chlorine, acids, and low pH levels often lead to corrosion.

Study Title | Key Findings |

|---|---|

Water Chemistry and Processing Effects on the Corrosion Degradation of Copper Tubing in Cooling Water Systems | Water quality and chlorine levels greatly affect copper pipe corrosion. |

Early Corrosion Failure of Copper Tubing Used in Air-Conditioning Units | Organic acids and chloride are major causes of corrosion. |

Hot-Water Corrosion Failure of a Hard-Drawn Copper Tube | High chlorine and low pH caused pipe damage and leaks. |

To avoid problems, use insulated pipes or coatings in tough environments. These steps protect pipes from damage and extend their life.

Budget and Cost Factors

Your budget is important when picking copper pipes. Copper pipes cost more upfront but last longer and need less care. Flexible copper pipes save time and money during installation.

Tip: Spend more on good copper pipes now to save money later.

Recycled copper pipes are a cheaper and eco-friendly option. They work well without lowering quality. By balancing costs and system needs, you can pick pipes that are both affordable and reliable.

Pipe Size and Thickness Requirements

Picking the right pipe size and thickness is very important. These factors affect how well refrigerants move in your air conditioner. Pipes that are too small or thin can block refrigerant flow. This lowers cooling efficiency. Pipes that are too big waste energy and cost more to install.

Why Pipe Size and Thickness Are Important

The size of copper pipes impacts key parts of your system:

Phase Change Efficiency: Correct pipe size helps refrigerants switch between gas and liquid. This process is needed for proper cooling.

Oil Return: Right pipe size keeps the compressor lubricated. This reduces wear and makes the system last longer.

Thermal Efficiency: Pipes that are too short or long can cause uneven cooling. This lowers the system's overall performance.

Pressure Regulation: Properly sized pipes keep refrigerant flow steady. This avoids turbulence and ensures even cooling.

Tips for Choosing the Right Pipe Size

When selecting copper pipes, think about your system's refrigerant type and pressure. High-pressure refrigerants like R410A may need thicker pipes. Also, consider the pipe length. Longer pipes might need larger diameters to keep pressure steady.

Tip: Check your air conditioner's guide for the best pipe size and thickness. This helps your system work better and saves energy.

Choosing the right pipe size improves reliability and cuts energy costs. It also lowers the chance of leaks or breakdowns, keeping your air conditioner working well for years.

Copper pipes are vital for air conditioning systems. They move refrigerants efficiently and help transfer heat well. These pipes are strong and work with modern refrigerants, making them great for homes and businesses. Smaller copper tubes improve cooling and lower material costs. New designs like MicroGroove tubes use less refrigerant and fin material, boosting performance.

When picking copper pipes, think about your system's needs, the environment, and your budget. Insulated copper pipes stop rust and save energy, making them last longer. They are perfect for multi-split systems or upgrading older ones. Choosing the right pipes ensures your system works well and saves money.

Tip: Make sure your copper pipes match your system's refrigerant and pressure needs.

Knowing how copper pipes help cooling systems lets you make better choices. This improves your air conditioner's performance and makes it last longer.

FAQ

Why are copper pipes better for air conditioning systems?

Copper pipes are strong and last a long time. They resist rust and move heat well. These features make them perfect for cooling systems. They also work with new refrigerants, staying reliable for years.

How do insulated copper pipes save energy?

Insulated pipes stop heat from escaping during refrigerant movement. This keeps cooling steady and uses less energy. You save money on electricity while your system works better.

Are copper pipes safe for air conditioners?

Yes, copper pipes follow safety rules for refrigeration. They handle high pressure and heat without breaking. Their rust resistance stops leaks, keeping systems safe and dependable.

Can copper pipes be reused?

Copper pipes can be recycled completely. Recycling cuts waste and helps the environment. It also reuses materials without lowering their quality.

What should you think about when picking copper pipes?

Look at refrigerant type, system pressure, and surroundings. Pipe size and thickness are also important for smooth refrigerant flow. Choosing the right pipes makes your system work well and last longer.

See Also

The Benefits of Selecting Copper Pipes for Cooling Systems

Transforming Air Conditioning with High-Quality Copper Pipes

The Importance of Pure Copper Pipes for Efficient Cooling