Review of the Best Copper Pipes for Air Conditioners

Review of Top Air Conditioning Copper Pipes

Copper pipes are indispensable in air conditioning systems, renowned for their exceptional thermal conductivity and durability. Their ability to efficiently transfer heat not only ensures optimal performance but also leads to significant energy savings. Choosing the right copper pipes is crucial for longevity and reliability in HVAC systems. This review blog post will delve into the importance of selecting high-quality copper pipes, exploring top brands like Mandev, Mexflow, and Type K. Join us on this journey to discover the best copper pipes for your air conditioning needs.

Personal Experience with Copper Pipes

Initial Installation

Choosing the wrong copper pipes

In the summer of 2020, a series of pinhole leaks plagued residents in Folsom, CA, due to the city's water composition. The high pH levels and chlorine residual content in the water triggered corrosion in copper piping, leading to widespread issues. This real-life scenario highlighted the critical importance of selecting high-quality copper pipes from reputable manufacturers.

Immediate issues faced

Upon installation of substandard copper pipes, immediate repercussions surfaced for many homeowners. Pinhole leaks became a common occurrence, causing water damage and financial strain. The inferior quality of the pipes exacerbated by corrosive elements in the water accelerated the deterioration process, resulting in costly repairs and disruptions to daily life.

Detailed Review of Top Copper Pipes

Mandev Copper Pipes

Features

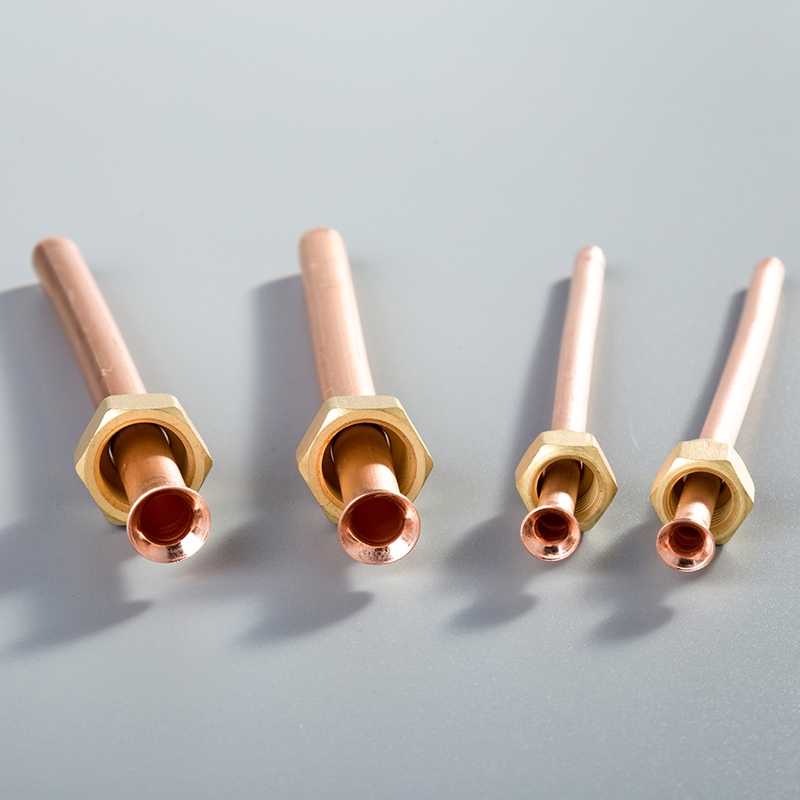

Mandev copper pipes and tubes cater to the air conditioning industry with two distinct categories.

The first category includes the One End Expanded Copper Pipe known as MT - Eco Self connect and MT - Eco Self connect +, boasting an outer diameter ranging from 4.76 mm to 54.1 mm.

The second category comprises the Pancake Copper Coil Tube named MT Eco Flex and MT Eco Flex +, offering an outer diameter spanning from 4.76 mm to 22.2 mm.

Pros and Cons

Pros:

Versatile options for different applications in air conditioning systems.

Wide range of outer diameters to suit various project requirements.

Known for their durability and reliability in HVAC installations.

Cons:

Limited availability in certain regions may pose challenges for procurement.

Pricing might be higher compared to other copper pipe brands due to specialized features.

Mexflow Copper Pipes

Features

Mexflow copper pipes, manufactured by Mehta Tubes Limited, are specifically designed for the Heating Ventilation Air Conditioning and Refrigeration industry.

Available in plain tubes of 10 feet length, these pipes offer a diverse range of outer diameters from 4.76 mm to 159 mm and wall thicknesses from 0.35 mm to 3.0 mm.

Additionally, Mexflow provides pancake coils measuring 50 feet in length with outer diameters ranging from 4.76 mm to 19.05 mm and wall thicknesses from 0.41 mm to 1.65 mm.

Pros and Cons

Pros:

Suitable for a wide array of HVAC applications including VRF VRV, Split ACs, Window ACs, and Ductable ACs.

Compatibility with R410A refrigerant ensures optimal performance in air conditioning systems.

Offers flexibility in installation due to a variety of available sizes.

Cons:

May require professional handling during installation due to specific coil configurations.

Higher wall thickness options might lead to increased costs compared to thinner alternatives.

Type K Copper Pipes

Features

Type K copper pipes stand out as a top choice for their thick wall construction, ensuring high durability suitable for various applications such as water distribution, fire protection, oil systems, and HVAC installations.

These pipes are available in both rigid and flexible forms, providing versatility for different projects based on specific requirements.

Pros and Cons

Pros:

Exceptional durability making them ideal for long-term usage without frequent replacements.

Versatility in application due to availability in both rigid and flexible forms.

Cons:

Thicker walls may lead to challenges during installation in tight spaces or intricate designs.

Higher initial investment cost compared to thinner copper pipe options.

Sequence of Events and Issues Encountered

Installation Process

Step-by-step guide

Begin by measuring the required length of copper pipes accurately to avoid unnecessary cuts.

Clean the ends of the pipes thoroughly using a suitable cleaning solution to remove any debris or contaminants.

Apply flux to the cleaned pipe ends and fittings before assembling them together securely.

Use a propane torch to heat the joint evenly until the solder melts and creates a tight seal.

Allow the soldered joints to cool naturally without any external assistance.

Common pitfalls

Neglecting proper cleaning of pipe ends can lead to weak joints and potential leaks.

Overheating the pipes during soldering may cause damage to both the pipes and surrounding components.

Inadequate support for long runs of copper piping can result in sagging or stress on the connections over time.

Performance Over Time

Short-term performance

In the initial stages, copper pipes exhibit exceptional thermal conductivity, ensuring efficient heat transfer within air conditioning systems. The seamless flow of refrigerant through these pipes contributes to quick cooling cycles, enhancing overall system performance.

Long-term durability

With regular maintenance and upkeep, copper pipes can withstand years of operation without significant degradation. Their resistance to corrosion and oxidation prolongs their lifespan, providing reliable service throughout the lifecycle of an air conditioning unit.

Troubleshooting

Common issues

One common issue that arises with copper pipes is pinhole leaks caused by external factors like water composition or improper installation techniques.

Corrosion due to exposure to harsh chemicals or environmental elements can weaken the structural integrity of copper piping over time.

Solutions and tips

To address pinhole leaks, consider reinforcing affected areas with epoxy or professional-grade sealing products for temporary fixes.

Implement routine inspections and maintenance schedules to detect early signs of corrosion or wear on copper pipes, preventing extensive damage in the long run.

When selecting copper pipes for air conditioning systems, the importance of quality cannot be overstated. Opting for high-quality copper pipes ensures longevity and efficiency in HVAC operations. Among the top air conditioning copper pipes reviewed, Mandev, Mexflow, and Type K offer exceptional features tailored to diverse applications. Installers worldwide endorse copper pipes for their reliability and recyclability, making them the preferred choice in the industry.

See Also

The Benefits of Selecting Copper Tubing for Air Conditioning

The Impact of Copper Piping on Air Conditioning Innovation

The Importance of Copper Tubing for Effective Air Conditioning

Key Factors in the Copper Piping Revolution for Air Conditioning

Exploring 5 Methods Copper Tubing Transforms Air Conditioning