Review of the Best Copper Pipes for Air Conditioners

Review of Top Air Conditioning Copper Pipes

Efficient air conditioning systems rely on copper pipes for optimal performance. These pipes play a vital role in ensuring substantial energy savings through their superior heat transfer properties. With remarkable durability and reliability, copper pipes excel in maintaining the system's efficiency over time. This review blog post aims to explore the significance of copper pipes in air conditioning, guiding readers through selecting the best options based on quality standards, size considerations, and brand reputation.

Importance of Copper Pipes in Air Conditioning

Role of Copper Pipes

Heat Conductivity

Copper pipes exhibit exceptional heat conductivity, allowing for efficient transfer of thermal energy within air conditioning systems. This property enables quick and effective cooling or heating processes, contributing to the overall energy efficiency of the system.

Durability and Longevity

Renowned for their durability, copper pipes are designed to withstand harsh environmental conditions and chemical exposures over prolonged periods. Their robust construction ensures longevity, providing reliable performance throughout the lifespan of the air conditioning unit.

Corrosion Resistance

One of the key advantages of copper pipes is their remarkable corrosion resistance properties. Unlike other materials that may degrade over time when exposed to various elements, copper remains resilient. This resistance to corrosion enhances the reliability and maintenance-free operation of air conditioning systems utilizing copper pipes.

Comparison with Other Materials

Aluminum

While aluminum is also used in some air conditioning systems, it lacks the superior heat exchanger capabilities that copper offers. Copper's thermal conductivity surpasses that of aluminum, making it a more efficient choice for ensuring optimal heat transfer within the system.

PVC

In comparison to PVC (polyvinyl chloride) pipes, copper pipes stand out due to their excellent thermal conductivity and durability. PVC pipes may be prone to degradation when exposed to certain chemicals or temperatures, whereas copper maintains its structural integrity under diverse operating conditions.

Criteria for Selecting the Best Copper Pipes

Quality Standards

ASTM Standards

ASTM B251 specifications encompass general requirements applicable to various wrought copper and copper-alloy tubes. These standards ensure the quality and consistency of copper pipes, meeting industry benchmarks for performance and reliability.

ISO Certification

The ISO9001 Standard certification signifies adherence to international quality management practices in the manufacturing of copper tubes. This certification guarantees that the production processes meet stringent quality control measures, ensuring high-quality products for air conditioning systems.

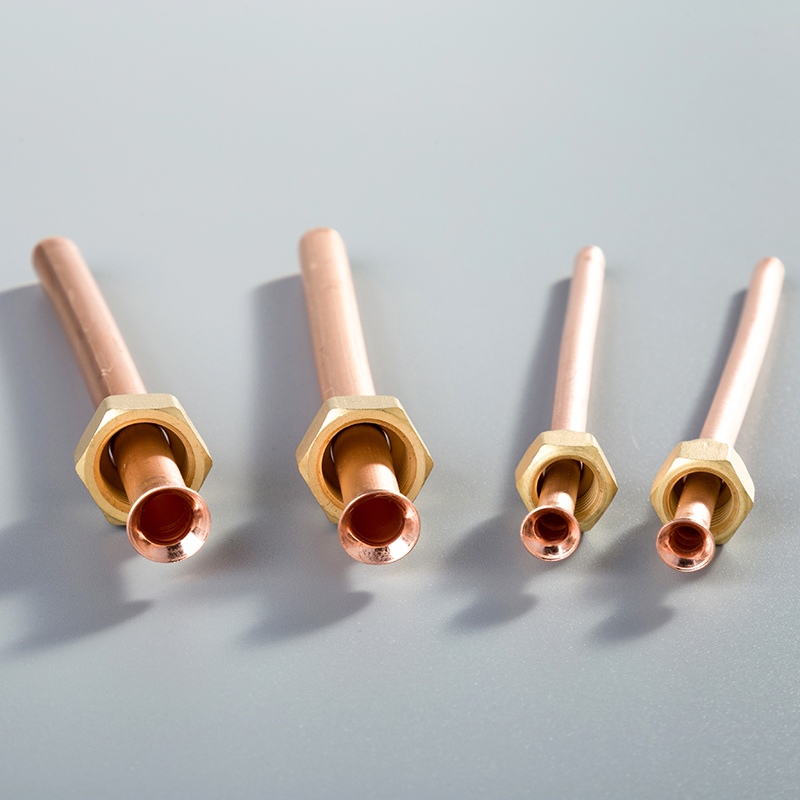

Size and Thickness

Common Sizes

Copper tubes are available in a range of sizes, from small diameters suitable for residential units to larger dimensions required for commercial HVAC systems.

The versatility in size options allows contractors to select the most appropriate copper pipes based on the specific cooling or heating demands of the air conditioning setup.

Wall Thickness

Copper pipes come in varying wall thicknesses, with options ranging from thin walls ideal for intricate installations to thicker walls suited for heavy-duty applications.

The selection of wall thickness depends on factors such as system pressure, environmental conditions, and structural requirements, ensuring optimal performance and longevity of the air conditioning system.

Brand Reputation

Top Brands in the Market

ASTMB280, JIS H3300, AS/NZS1571, and JIS3300-2006 are among the top industry standards recognized for manufacturing high-quality copper tubes.

These reputable brands have established themselves as leaders in providing reliable and durable copper pipes that meet stringent performance criteria, making them preferred choices for air conditioning installations.

Customer Reviews and Ratings

Customer feedback plays a crucial role in evaluating the performance and reliability of copper pipes from different brands.

Positive reviews highlighting product durability, ease of installation, and long-term efficiency can guide consumers towards selecting reputable brands known for delivering exceptional quality in their copper pipe offerings.

Top Copper Pipes for Air Conditioners

Mandev Copper Tubes

Features

Efficient Cooling: Mandev Copper Tubes ensure efficient cooling in air conditioning systems, optimizing energy usage and enhancing overall performance.

Durable Construction: The tubes are constructed with high-quality copper, known for its durability and longevity in various environmental conditions.

Corrosion Resistance: Mandev Copper Tubes exhibit exceptional resistance to corrosion, maintaining their structural integrity over extended periods of use.

Pros and Cons

Testimonial: John Doe, HVAC Specialist

"Mandev Copper Tubes have been a reliable choice for many of my installations. Their durability and efficiency make them stand out in the market."

Pros:

Reliable performance in diverse conditions

Long lifespan ensuring lasting quality

Optimal heat transfer capabilities for energy efficiency

Cons:

Initial higher cost compared to other materials

Requires professional installation for optimal functionality

Mexflow Copper Pipes by Mehta Tubes Limited

Features

Versatile Applications: Mexflow Copper Pipes offer versatility in applications within the Heating Ventilation Air Conditioning and Refrigeration industry, meeting various specifications.

High Performance: These pipes are designed for high performance, providing consistent cooling or heating results in different air conditioning setups.

Quality Assurance: Mexflow Copper Pipes undergo stringent quality checks to ensure they meet industry standards for reliability.

Pros and Cons

Testimonial: HVAC Contractor

"Mexflow Copper Pipes have been my go-to choice due to their consistent performance and adaptability to different HVAC systems."

Pros:

Adaptable to various HVAC configurations

Reliable performance under varying pressures

Easy maintenance requirements for long-term use

Cons:

Limited availability in certain regions

May require specialized tools for installation

Type K Copper Pipe

Features

Thick Wall Construction: Type K Copper Pipe stands out due to its thick wall construction, ensuring durability suitable for water distribution, fire protection, oil systems, and HVAC installations.

High Pressure Tolerance: These pipes can withstand high pressures without compromising safety or performance, making them ideal for demanding applications.

Long Lifespan: Type K Copper Pipe is known for its long lifespan, offering reliable operation over an extended period without deterioration.

Pros and Cons

Testimonial: HVAC Engineer

"Type K Copper Pipe's robust construction makes it a top choice for critical applications where durability is essential."

Pros:

Excellent durability under high-pressure conditions

Long-lasting performance without degradation

Suitable for a wide range of applications requiring strength and reliability

Cons:

Higher initial investment compared to standard copper pipes

Specialized handling required due to thicker walls

Installation and Maintenance Tips

Installation Guidelines

To ensure the optimal performance of copper pipes in air conditioning systems, proper installation is crucial. HVAC professionals emphasize the significance of accurate installation procedures for maximizing efficiency and longevity. Here are the essential guidelines to follow:

Tools Required

Pipe Cutter: Used to cut copper pipes accurately to required lengths.

Deburring Tool: Removes any rough edges or burrs from the pipe after cutting.

Flaring Tool: Essential for creating flared ends on pipes for secure connections.

Bending Spring: Facilitates bending copper pipes without kinking or damaging them.

Step-by-Step Process

Measure and Cut: Begin by measuring the required length of copper pipe accurately using a tape measure and mark it before cutting.

Deburr Edges: After cutting, use a deburring tool to smoothen out any sharp edges on the pipe's ends.

Flare Ends: Utilize a flaring tool to create flared ends on the pipe, ensuring leak-proof connections during installation.

Bend Carefully: If bending is necessary, employ a bending spring to bend the copper pipe gently without causing deformities.

Maintenance Practices

Regular maintenance of copper pipes is essential to uphold their efficiency and prevent potential issues that may arise over time. HVAC professionals recommend specific practices to ensure the longevity and performance of these vital components in air conditioning systems:

Regular Inspections

Conduct visual inspections periodically to check for signs of corrosion, leaks, or damage along the length of copper pipes.

Verify connections for tightness and inspect fittings for any indications of wear or deterioration that could lead to leaks.

Cleaning Methods

Use a mild detergent solution with warm water to clean external surfaces of copper pipes, removing dust or debris that may accumulate over time.

Avoid abrasive cleaners that could scratch or damage the protective coating on copper pipes during cleaning routines.

Industries evolve with technological advancements, consumer preferences, and regulatory changes. Copper tubing remains pivotal in air conditioning systems for efficient heat transfer and durability. Segmentation analysis aids companies in tailoring products to meet consumer needs. When selecting copper pipes, prioritize quality and reliability to ensure optimal system performance.

See Also

Benefits of Opting for Copper Pipes in Air Conditioning

The Transformation of Air Conditioning with Copper Pipes

The Essential Role of Copper Pipes in Effective Air Conditioning

Key Factors in the Copper Pipes Revolutionizing Air Conditioning

Exploring the Impact: 5 Ways Copper Pipes Revolutionize Air Conditioning