Step-by-Step Guide: How to Solder Copper Pipes

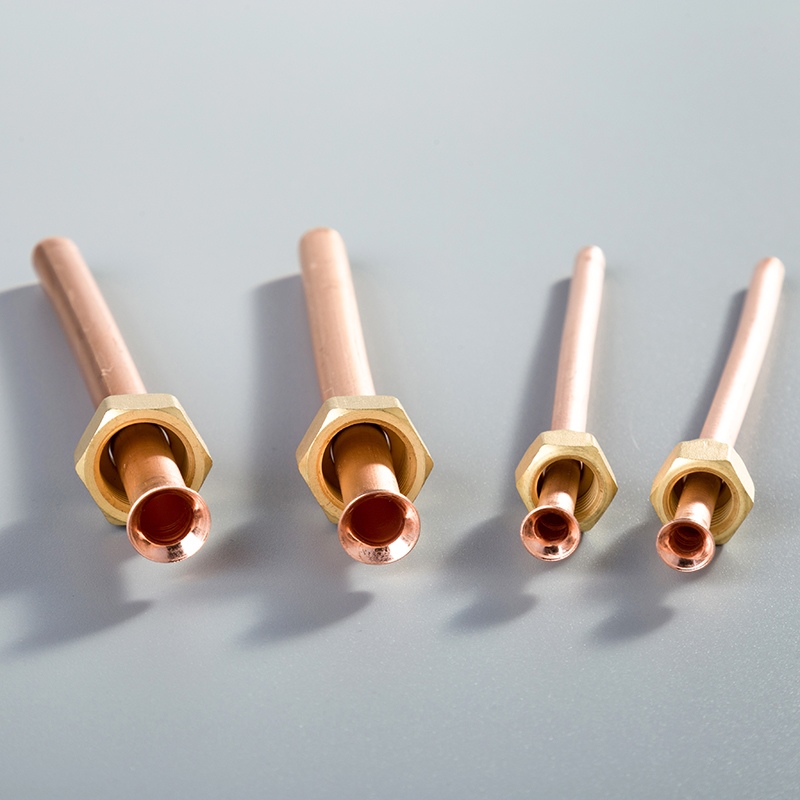

Copper pipes play a vital role in plumbing and DIY projects, making soldering copper pipes a fundamental skill. The process not only ensures secure connections but also guarantees the durability and versatility of the plumbing system. Understanding the nuances of types of copper pipe is essential for successful soldering endeavors. From threaded copper pipe to type l copper pipe, each variation serves a specific purpose, enriching the applications of this traditional yet reliable technique.

Tools and Materials Needed

When embarking on a project involving soldering copper pipes, having the right tools and materials is crucial for a successful outcome. Here is a breakdown of the essential items required:

Essential Tools

To begin, a pipe cutter is indispensable for accurately cutting the copper pipes to the desired length. This tool ensures clean and precise cuts, which are vital for seamless connections. Next, a torch becomes your best ally in heating the pipes and fittings to the optimal temperature for soldering. Lastly, a flux brush is essential for applying flux evenly on the surfaces to be soldered, promoting strong adhesion between the materials.

Required Materials

When it comes to materials, type l copper pipe stands out as a reliable choice due to its durability and versatility in various applications. Additionally, solder plays a critical role in creating secure joints by melting and filling the gaps between connected pipes. Completing this trio is flux, which aids in cleaning and preparing the surfaces before soldering, ensuring a strong bond.

Safety Equipment

Prioritizing safety during any project is paramount. Equip yourself with gloves to protect your hands from heat and sharp edges while handling materials. Furthermore, donning safety glasses shields your eyes from potential sparks or debris that may occur during the soldering process.

Preparation Steps

Measuring and Cutting

To initiate the soldering process effectively, accurate measurements and precise cuts are imperative. Utilizing a pipe cutter ensures clean and smooth cuts on the copper pipes, facilitating seamless connections. By employing this tool, individuals can achieve the desired length with precision, setting the foundation for a secure joint. Ensuring accurate measurements is equally crucial to prevent any discrepancies during the assembly process.

Cleaning the Pipes

Before proceeding with soldering, it is essential to prepare the surfaces adequately by cleaning them thoroughly. Using either sandpaper or Scotchbrite, remove any impurities or oxidized layers present on the pipe ends. This meticulous cleaning process guarantees optimal adhesion between the materials, promoting a robust and enduring connection. Emphasizing the importance of clean surfaces, this step significantly contributes to the overall integrity of the soldered joint.

Applying Flux

An integral part of the soldering procedure involves applying flux onto the cleaned surfaces before joining them together. Achieving an even application using an acid brush ensures uniform coverage, enhancing the effectiveness of the flux in facilitating solder flow. Additionally, preparing the fitting hub by applying flux sets the stage for a seamless connection between components. By meticulously following these steps, individuals can optimize their soldering experience and create durable plumbing installations that stand the test of time.

Soldering Process

Heating the Joint

To begin the soldering process effectively, direct the torch flame precisely towards the joint area. Maintain a consistent distance between the flame and the fitting to ensure optimal heating. By controlling the torch with precision, you can avoid overheating and achieve a uniform temperature distribution along the joint.

Applying Solder

When it's time to apply solder, remember that capillary action is your ally in creating a strong bond. Touch the solder to the heated joint, allowing it to melt and flow smoothly into the connection. This natural process guarantees a secure attachment by filling any gaps between the pipes seamlessly. After applying the solder, allow ample time for the joint to cool naturally without any external interference.

Inspecting the Joint

After completing the soldering process, conduct a thorough inspection of the joint to verify its integrity. Check meticulously for any signs of leaks or irregularities that may compromise its strength. Ensuring a secure connection is paramount for long-lasting plumbing installations; therefore, confirm that all components are firmly joined without any gaps or loose ends. By conducting a detailed examination post-soldering, you guarantee a reliable and durable outcome for your project.

Recap of the soldering process:

Review the meticulous steps from cutting to cleaning, ensuring a flawless connection.

Revisit the significance of accurate measurements and even flux application for optimal results.

Importance of each step for a secure connection:

Emphasize the critical role of precise cuts in preventing leaks and enhancing durability.

Highlight the necessity of thorough cleaning for strong adhesion and lasting plumbing installations.

Suggestions for further practice and safety tips:

Practice measuring accurately and applying flux uniformly for improved soldering proficiency.

Prioritize safety by wearing gloves and safety glasses to safeguard against potential hazards during soldering tasks.

See Also

Basic Guide: Soldering Copper Pipes for Novices

Quick Guide: Soldering Copper Pipes Safely

Expert Advice: Simple Tricks for 1 1/2 Copper Pipes