Steps to Remove a Compression Fitting from a Copper Pipe

Steps to Remove a Compression Fitting from a Copper Pipe

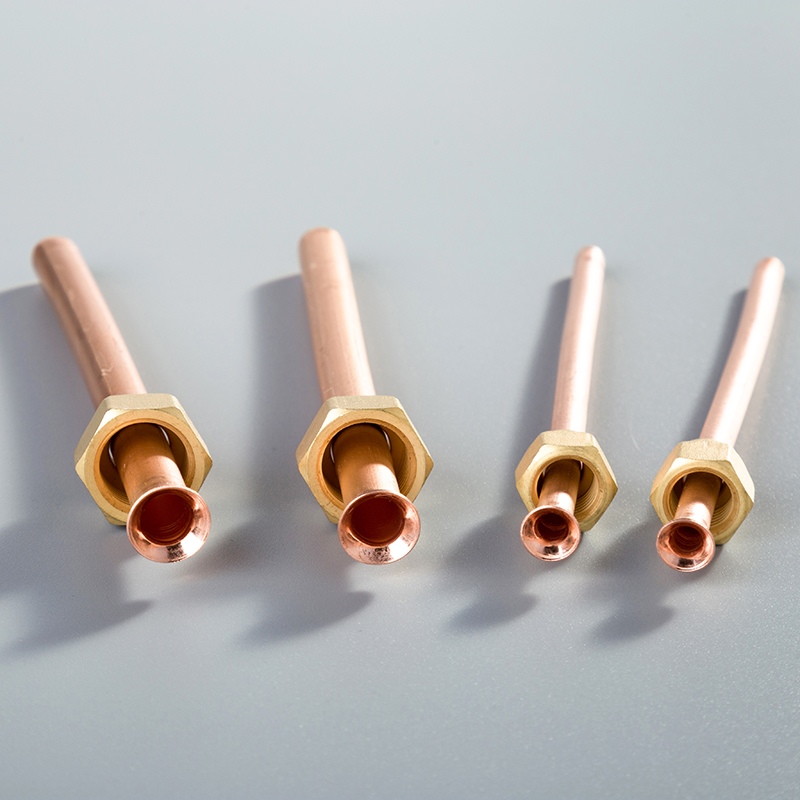

Compression fittings are widely used in various industries for their efficiency and reliability. Ideal for high-pressure applications, these fittings offer a secure connection between pipes without the need for soldering. Understanding how to remove a compression fitting from a copper pipe is crucial for maintenance tasks. Prior to initiating the removal process, it is essential to consider safety precautions to prevent accidents. Additionally, having the necessary tools and materials readily available ensures a smooth removal procedure.

Preparing for the Removal

Gathering Tools and Materials

List of Required Tools

Precision 'Jab Saw': Essential for making precise cuts during the removal process.

Vice-Grips: Used for a secure grip and handling of various components.

Adjustable Wrench: Necessary for loosening nuts and bolts securely.

Safety Gear and Precautions

Gloves, coveralls, respirators: Each plays a crucial role in ensuring safety during plumbing tasks.

Eye protection: Vital for safeguarding your eyes from potential harm while working.

Back and Knee Protection: Due to the nature of plumbing work, protecting your back and knees is paramount.

Shutting Off Water Supply

Locating the Main Water Valve

Before commencing the removal process, it is imperative to locate the main water valve to ensure a safe working environment.

Draining the Pipe

Draining the pipe before removal prevents unnecessary spillage or leaks, reducing potential mess and hazards during the procedure.

Step-by-Step Removal Process

Loosening the Compression Nut

To begin the removal process, position the wrench securely on the compression nut. Apply steady pressure in a counterclockwise direction to loosen the nut effectively. Ensure a firm grip on the wrench to prevent slippage and maintain control over the nut.

Applying Penetrating Oil for Stuck Nuts

In cases where the compression nut is stubbornly stuck, utilize penetrating oil as a lubricant. Allow the oil to seep into the threads of the nut for enhanced loosening. Wait for a few minutes to let the oil work its way through before attempting to loosen the nut again.

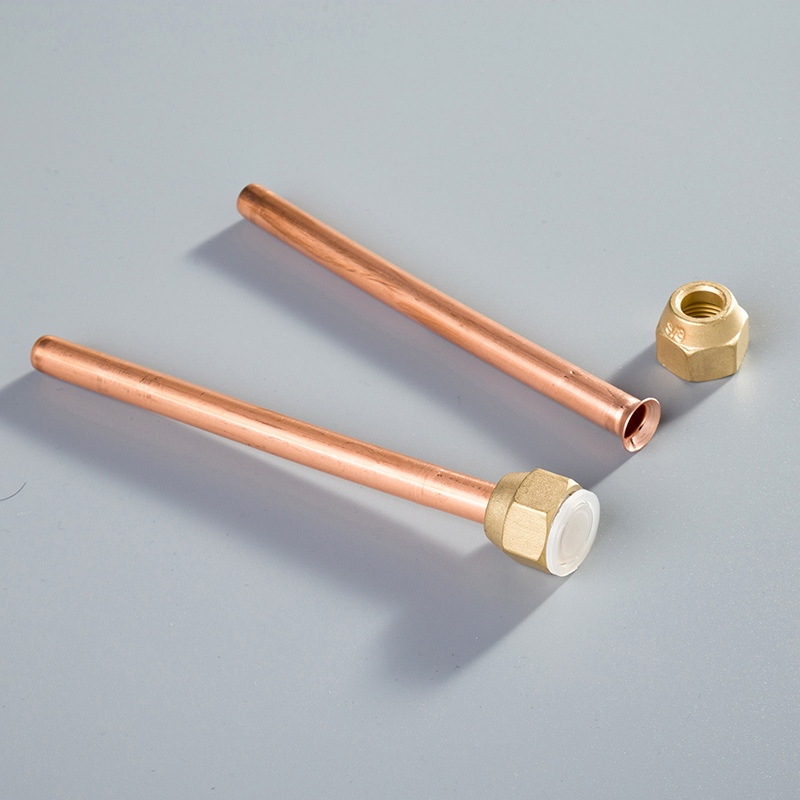

Removing the Compression Ring

Once the nut is loosened, focus on removing the compression ring from the copper pipe. Employ gentle twisting motions to ease off the ring from its position. Exercise caution to avoid damaging the pipe while detaching the ring.

Troubleshooting Stuck Rings

If you encounter resistance when removing the compression ring, consider using a ferrule puller tool. This specialized tool can assist in effortlessly pulling off even stubborn rings from copper pipes. Remember to maintain a steady hand and apply consistent pressure for optimal results.

Detaching the Compression Fitting

With both the nut and ring removed, proceed with detaching the compression fitting itself from the pipe. Gently pull off the fitting while ensuring smooth separation from any remaining components. Once detached, take a moment to carefully inspect the end of your copper pipe for any signs of damage or wear.

Troubleshooting Common Issues

Dealing with Corroded Fittings

When faced with corroded fittings, it is essential to address the issue promptly to prevent further damage. The presence of corrosion can lead to rigidity and strength reduction in the fittings, impacting their overall performance. To tackle this challenge effectively, consider the following strategies:

Using a Hacksaw or Dremel Tool:

Employing a hacksaw or Dremel tool can facilitate the removal of corroded fittings. These tools enable precise cutting, allowing you to navigate through the affected area with accuracy.

Applying Muriatic Acid:

Muriatic acid can be a valuable solution for combating stubborn corrosion on fittings. By applying a small amount of acid to a clean cloth and rubbing it over the affected area, you can initiate the removal process effectively.

Addressing Stuck Compression Nuts

Stuck compression nuts can pose a significant challenge during the removal process, requiring careful attention and strategic solutions. To overcome this obstacle and ensure a successful extraction, consider the following approaches:

Using a Nut Splitter:

A nut splitter is a specialized tool designed to assist in separating stuck compression nuts from pipes. By utilizing this tool correctly, you can effectively split the nut and proceed with the removal process seamlessly.

Alternative Methods:

In cases where traditional methods may not suffice, exploring alternative approaches can be beneficial. Techniques such as applying mild heat from outside or using penetrating oil can help loosen stuck nuts without causing damage.

Summarize the outlined procedures for removing a compression fitting from a copper pipe.

Prioritize examining the copper pipe for any potential damage post-removal.

Consider consulting with a professional plumber for complex removal scenarios.

Remember to adhere to safety guidelines and equip yourself adequately for future plumbing tasks.

See Also

Straightforward Guide: Attaching Compression Fittings to Bent Copper Pipes

Key Pointers for Utilizing 1/4 Copper Pipe Fittings

Basic Guide: Soldering a Copper Pipe for Novices