How Technology Enhances Quality Control in Copper Pipe Manufacturing

In copper pipe manufacturing, ensuring quality control is paramount to uphold the reputation of manufacturers. The rigorous testing processes at each production stage have solidified their standing in the industry. By automating quality control, organizations aim to reduce errors, increase inspection speed, and maintain product standards. Examine the role of technology in enhancing quality control for 1/4 3/8 twin copper pipe coils manuf. Technology has revolutionized this sector, offering innovative solutions that enhance efficiency and accuracy in quality assessments.

Technological Advancements in Quality Control

In the realm of copper pipe manufacturing, technological advancements have paved the way for significant improvements in quality control processes. These innovations have revolutionized the industry, offering manufacturers a competitive edge by enhancing efficiency and precision in their operations.

Automated Quality Control Systems

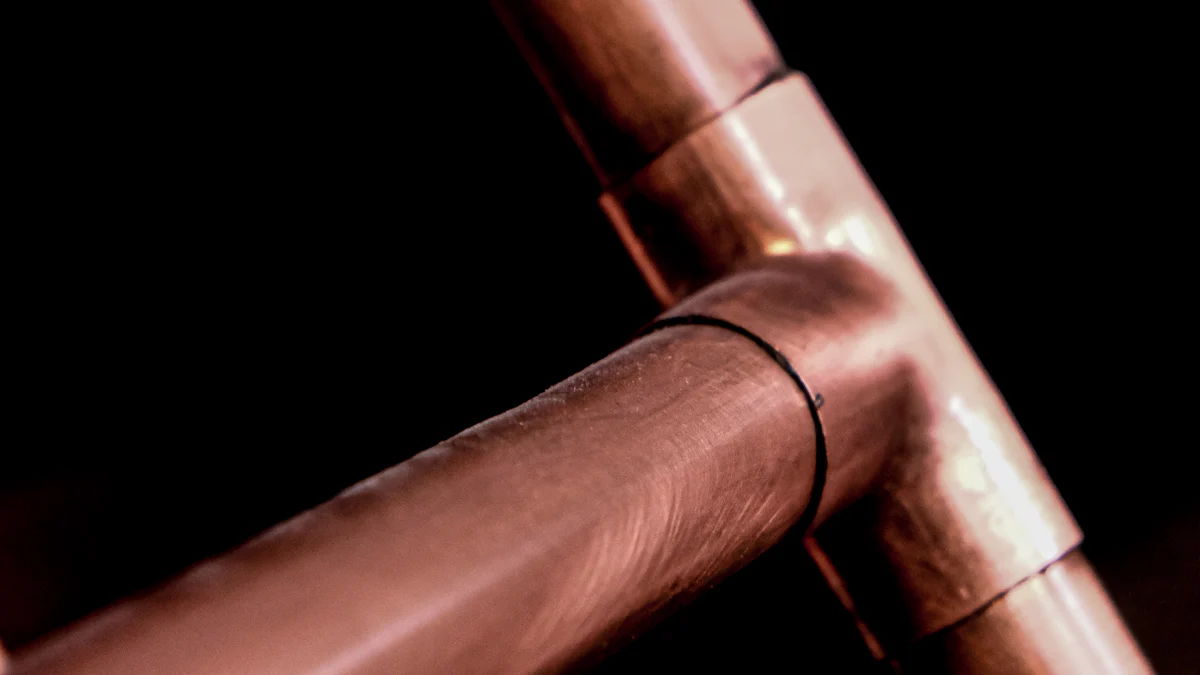

Implementing automated quality control systems has been a game-changer for manufacturers seeking to streamline their production processes. High-Speed Joint Inspection systems, for instance, utilize cutting-edge technology to swiftly examine the integrity of joints in copper pipes. By automating this crucial aspect of quality assessment, manufacturers can detect potential issues promptly and ensure that only top-notch products reach the market.

Visual indicators and logos play a pivotal role in maintaining quality standards throughout the manufacturing process. These Visual Indicators and Logos serve as visual cues that signify adherence to specific quality criteria. By incorporating these markers into their products, manufacturers can easily identify any deviations from the desired specifications and take corrective actions promptly.

Non-Destructive Testing Methods

Non-destructive testing methods have become indispensable tools in ensuring the quality and reliability of copper pipes. Eddy Current Testing techniques allow manufacturers to assess the structural integrity of copper tubes used in critical applications such as air-conditioning and refrigeration systems. This non-invasive method helps identify potential defects without compromising the integrity of the pipes.

Another essential non-destructive testing method is Ultrasonic Thickness Measurement, which enables precise measurement of copper pipe thickness. Particularly useful for large pipes, this method ensures that products meet stringent dimensional requirements without causing any damage during inspection.

Examine the role of technology in enhancing quality control for 1/4 3/8 twin copper pipe coils manuf

In the production of 1/4 3/8 twin copper pipe coils, technology plays a vital role in elevating quality control standards to new heights. RFID Systems offer real-time tracking and monitoring capabilities, allowing manufacturers to oversee every stage of production with unparalleled accuracy. By leveraging RFID technology, organizations can optimize workflow efficiency and minimize errors throughout the manufacturing process.

Furthermore, Decentralized Control Systems empower manufacturers with greater flexibility and control over their operations. By distributing decision-making authority across various production units, decentralized control systems enhance responsiveness and adaptability in dynamic manufacturing environments.

Specific Technologies in Copper Pipe Manufacturing

In the realm of copper pipe manufacturing, the implementation of specific technologies plays a pivotal role in ensuring the highest standards of quality control. By meticulously planning and executing quality measures, manufacturers can uphold their reputation for excellence in the industry.

Quality Plans and Execution

Pre-Production Planning

Prior to commencing production, meticulous Pre-Production Planning is essential to outline the quality benchmarks that need to be met at each stage. This strategic approach involves setting clear objectives, defining quality parameters, and establishing protocols to monitor adherence to these standards throughout the manufacturing process.

Real-Time Monitoring

Real-time monitoring emerges as a crucial aspect of maintaining quality control in copper pipe manufacturing. Through Real-Time Monitoring, manufacturers can track key performance indicators, identify deviations from set quality norms promptly, and take corrective actions swiftly. This proactive approach ensures that any potential issues are addressed in real-time, minimizing disruptions and enhancing overall product quality.

Equipment for Quality Assessment

Specialized Devices for Natural Gas Installations

The use of Specialized Devices tailored for natural gas installations is imperative to ensure that copper pipes meet stringent safety requirements. These devices are designed to assess critical aspects such as pressure resistance, leak detection, and material integrity specific to natural gas applications. By utilizing specialized equipment, manufacturers can guarantee that their products adhere to industry regulations and deliver optimal performance.

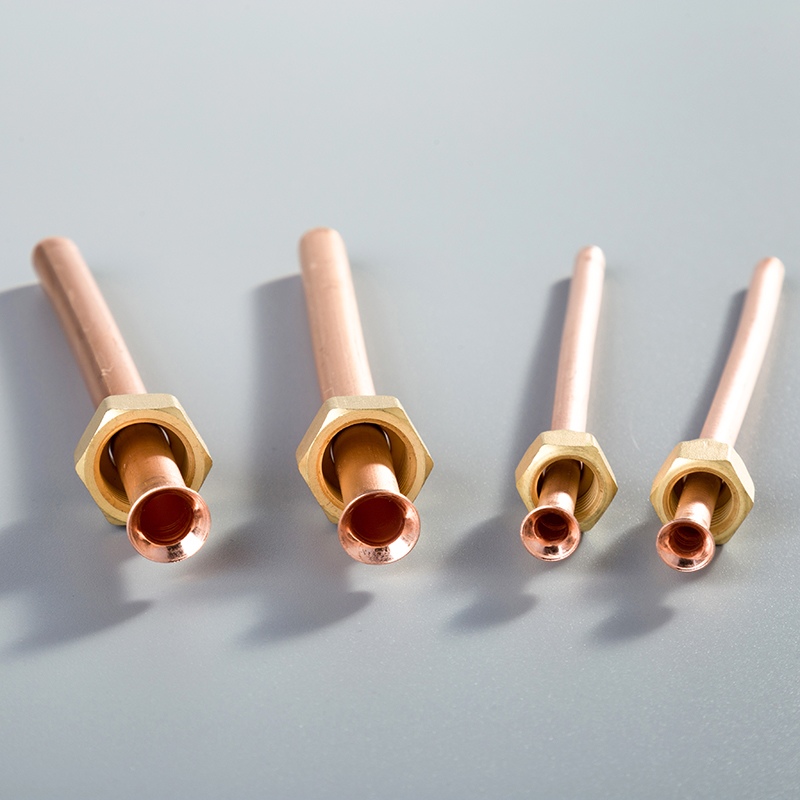

Standards Compliance (ASTM B42, B280)

Adhering to established standards such as ASTM B42 and B280 is non-negotiable in copper pipe manufacturing. These standards define the precise specifications for seamless copper tubes used across various applications like air conditioning, refrigeration systems, and plumbing. By ensuring compliance with these rigorous standards, manufacturers certify the reliability and durability of their products while instilling confidence in consumers regarding product safety and performance.

Flow-Induced Failure Mechanisms

Corrosion Prevention

Preventing corrosion is a paramount concern in maintaining the longevity of copper pipes within potable water systems. Robust Corrosion Prevention strategies involve implementing protective coatings or treatments on copper surfaces to inhibit corrosion processes effectively. By proactively addressing this potential issue through preventive measures, manufacturers safeguard the structural integrity of their products against corrosive elements present in water systems.

Material Inspection

Thorough inspection of raw materials is a fundamental step in ensuring the quality of copper pipes from inception. Material Inspection involves rigorous testing procedures to verify material purity, dimensional accuracy, and structural integrity before initiating the manufacturing process. By conducting comprehensive material inspections using advanced testing methods like spectroscopy or microscopy, manufacturers guarantee that only high-quality materials are utilized in their production processes.

Future Trends and Recommendations

Emerging Technologies

AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning are at the forefront of revolutionizing quality control in copper pipe manufacturing. By harnessing the power of AI algorithms, manufacturers can analyze vast amounts of data to identify patterns and anomalies that may indicate potential defects. Machine Learning models enable predictive maintenance strategies, allowing organizations to preemptively address issues before they escalate. The integration of AI technologies not only enhances the efficiency of quality control processes but also ensures the production of high-quality copper pipes that meet stringent industry standards.

IoT Integration

The integration of Internet of Things (IoT) technology offers unprecedented opportunities for enhancing quality control in copper pipe manufacturing. IoT devices embedded within production facilities collect real-time data on various parameters such as temperature, pressure, and flow rates. This continuous stream of information enables manufacturers to monitor the production process closely and detect deviations from expected norms promptly. By leveraging IoT integration, organizations can implement proactive quality measures that prevent defective products from entering the market, thereby safeguarding their reputation and ensuring customer satisfaction.

Manufacturers prioritize automating quality control processes to enhance efficiency and accuracy in defect identification. By utilizing automated systems, defects are promptly detected, reducing material wastage and ensuring product adherence to standards. The integration of IoT sensors offers solutions for optimizing oil/gas flow, preventing corrosion, and predicting maintenance needs effectively. Implementing remote operation through robots not only improves product quality but also enhances safety measures within manufacturing environments. Embracing these technological advancements is pivotal for the future of quality control in copper pipe manufacturing, ensuring continuous innovation and excellence in the industry.

See Also

Exploring Quality Assurance Techniques for Copper Pipe Coil Production

Perfecting Quality Management for Copper Pipe Coil Analysis

Innovative Approaches to Ensuring Copper Pipe Coil Quality

Exploring Cutting-Edge Technologies for Dual Copper Pipe Coils

Revealing the Next Generation of Copper Pipe Coil Technology