Comprehensive Guide to Thermal Insulation for Copper Pipes in Air Conditioners

Guide to Thermal Insulation for Copper Pipes in Air Conditioners

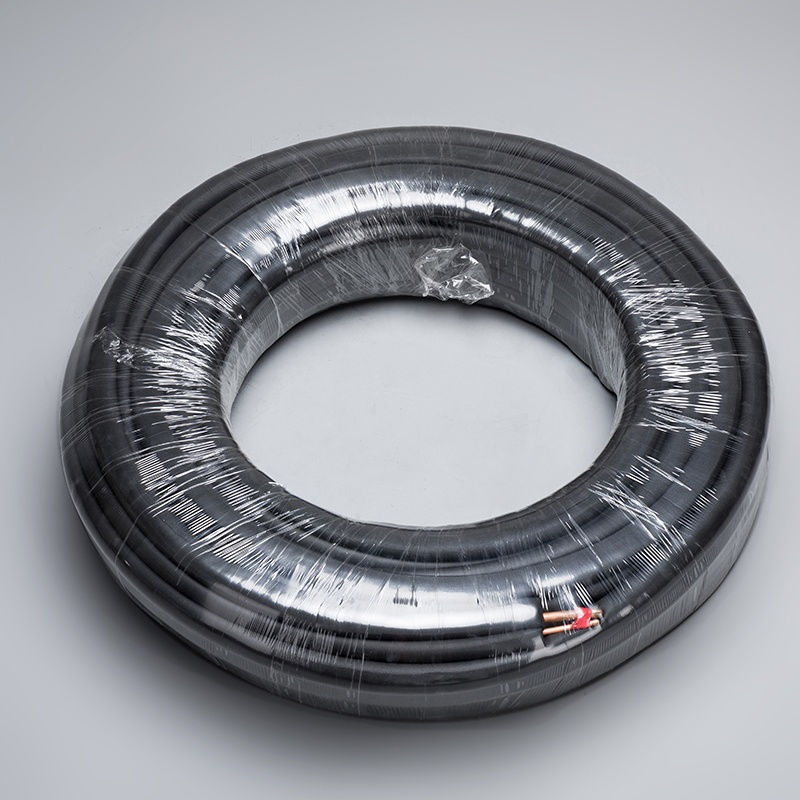

Insulating copper pipes in air conditioners is essential for maintaining energy efficiency and preventing heat loss. Homeowners who invest in proper insulation can save an average of $3.74 per linear foot annually. Without insulation, copper lines may not deliver the required cold refrigerant to the evaporator coil, impacting system performance. Additionally, uninsulated pipes lead to quicker heat loss, causing boilers to work harder to maintain desired temperatures. Understanding the significance of thermal insulation and choosing the right materials and techniques is key to optimizing your air conditioning system.

Importance of Thermal Insulation

Maintaining energy efficiency is crucial when it comes to air conditioning systems. By insulating copper pipes, homeowners can significantly reduce their energy consumption and achieve substantial cost savings. Reducing Energy Consumption is a primary benefit of proper insulation. When copper pipes are adequately insulated, heat loss or gain is minimized, allowing the system to operate more efficiently without unnecessary energy expenditure.

In addition to reducing energy consumption, effective thermal insulation plays a vital role in achieving Cost Savings for homeowners. Insulated copper pipes help maintain the desired temperature levels within the air conditioning system, reducing the workload on other components such as compressors and fans. This results in lower utility bills and overall cost-effectiveness for the household.

Preventing water leakage is another critical aspect of insulating copper pipes in air conditioners. Avoiding Damage caused by condensation buildup or leaks due to uninsulated pipes is essential for preserving the integrity of the entire system. Proper insulation not only protects against immediate damage but also ensures the Longevity of the air conditioning unit by preventing corrosion and deterioration over time.

Enhancing performance through thermal insulation contributes to maintaining optimal conditions within the air conditioning system. By Maintaining Optimal Temperature, insulated copper pipes ensure that refrigerant flows smoothly without any heat exchange with the surrounding environment. This leads to improved overall efficiency and performance of the AC unit, providing consistent cooling output when needed.

Moreover, Improving System Efficiency is a direct result of effective thermal insulation for copper pipes in air conditioners. Insulation materials like polyurethane foam or elastomeric rubber foam create a barrier that minimizes heat transfer, allowing the system to operate at its peak performance levels without unnecessary energy losses.

Types of Insulation Materials

Polyurethane Foam

Thermal Insulation Properties

Polyurethane foam, a favored choice for insulating copper pipes, boasts exceptional thermal insulation properties. It provides a reliable barrier against heat transfer, ensuring that the refrigerant within the pipes maintains its desired temperature efficiently. This material's ability to minimize heat exchange contributes significantly to the overall energy efficiency of air conditioning systems.

Moisture Resistance

In addition to its thermal insulation benefits, polyurethane foam offers remarkable moisture resistance capabilities. By preventing moisture buildup on the surface of copper pipes, this material safeguards against potential corrosion issues that could compromise the system's functionality. The moisture-resistant nature of polyurethane foam ensures long-lasting protection for the copper pipes in air conditioners.

Phenolic Foam

Durability

Phenolic foam stands out as a durable option for insulating copper pipes in air conditioning systems. Its robust structure and high-density composition make it highly resilient to external factors, ensuring long-term performance and reliability. With phenolic foam insulation, homeowners can trust in a solution that maintains its effectiveness over extended periods.

Application Methods

When it comes to applying phenolic foam insulation, various methods can be employed to achieve optimal results. Whether through spray application or rigid board installation, phenolic foam adapts well to different techniques, allowing for customized solutions tailored to specific project requirements. The versatility in application methods makes phenolic foam a versatile choice for insulating copper pipes effectively.

XLPE Insulation Tubing

Wall Thickness Variations

When considering XLPE insulation tubing for copper pipes in air conditioners, homeowners benefit from its versatile design that accommodates various wall thickness options. This flexibility allows for customized solutions based on specific project requirements and environmental factors. By selecting the appropriate wall thickness, individuals can ensure optimal insulation performance tailored to their air conditioning system's needs.

Usage Scenarios

XLPE insulation tubing finds extensive application in diverse scenarios within air conditioning systems. Whether in residential or commercial settings, this tubing offers a reliable solution for insulating copper pipes effectively. Its adaptability to different environments and conditions makes it a versatile choice for ensuring energy efficiency and system longevity. Homeowners can trust XLPE insulation tubing to provide consistent thermal protection and prevent heat loss or gain in their AC units.

Installation Techniques

Preparing the Pipes

Cleaning and Drying

To ensure proper insulation for copper pipes in air conditioners, start by thoroughly cleaning and drying the pipes. Use a clean cloth to wipe off any dust or debris that may have accumulated on the surface. This step is crucial as it allows the insulation material to adhere securely to the pipes without any obstructions. By maintaining a clean surface, you guarantee a seamless application of the insulation, enhancing its effectiveness in preventing heat transfer.

Measuring and Cutting Insulation

After cleaning the pipes, accurately measure the length of insulation needed for each section. XLPE Insulation Tubing offers various wall thickness options to accommodate different pipe diameters effectively. Once measured, carefully cut the insulation material to fit precisely around the copper pipes. Precision is key in this step to ensure complete coverage and optimal thermal protection for your air conditioning system.

Applying Insulation

Wrapping Techniques

When applying insulation to copper pipes, consider using wrapping techniques that provide a snug fit around the pipes. Aflex-Eco Nitrile Insulation Foam offers tubes with different wall thicknesses suitable for various pipe diameters, ensuring a customized fit. Begin wrapping the insulation material around the pipes in a tight spiral motion, overlapping each layer slightly for maximum coverage. This method creates a barrier that minimizes heat exchange and enhances energy efficiency.

Securing Insulation

After wrapping the copper pipes with insulation material, secure it in place to prevent any gaps or movement. Closed-cell insulation materials like Aerofoam® XLPE Polyolefin Insulation Tubes are durable and long-lasting, offering reliable protection once properly secured. Use adhesive tapes or fasteners to secure the insulation firmly along its length, ensuring it remains intact over time. Properly securing the insulation guarantees consistent thermal performance and prolongs the lifespan of your air conditioning system.

Checking for Gaps

Sealing Methods

To avoid heat loss or gain through gaps in the insulation, employ effective sealing methods along joints or connections between sections of copper pipes. Special insulations designed for small pipes and electrical pipelines provide fire-rated protection against moisture and improve thermal efficiency when sleeved over hot or cold water pipes. Apply sealants or tapes at junction points to create a seamless barrier that prevents energy wastage due to leaks or inadequate coverage.

Ensuring Complete Coverage

Inspect all insulated sections of copper pipes meticulously to ensure complete coverage without any exposed areas. PVC (Polyvinyl Chloride) insulation is a durable option resistant to moisture and UV radiation suitable for outdoor HVAC installations where exposure is higher. Check for any gaps or gaps in coverage along the entire length of the pipes and address them promptly by adding additional layers of insulation where necessary. Complete coverage guarantees optimal thermal efficiency and protects your air conditioning system from unnecessary energy losses.

Maintenance Tips

Regular Inspections

Conduct regular inspections of the insulated copper pipes to ensure optimal thermal efficiency and performance.

Check for any signs of wear, damage, or gaps in the insulation that may compromise the system's effectiveness.

Inspect the entire length of the pipes meticulously, focusing on areas prone to moisture buildup or external damage.

Repairing Damages

Address any damages or gaps in the insulation promptly to prevent energy losses and maintain system efficiency.

Use durable materials like Closed-cell insulation to repair any worn-out sections effectively.

Apply sealants or tapes at junction points to create a seamless barrier that prevents heat exchange and ensures consistent thermal protection.

Recap: Enhancing energy efficiency and preventing heat loss are crucial benefits of insulating copper pipes in air conditioners. Proper insulation not only reduces utility bills but also ensures optimal performance of the HVAC system, benefiting homeowners in the long run.

Summary: From polyurethane foam to XLPE insulation tubing, a variety of materials offer exceptional thermal protection for copper pipes. Techniques like measuring and cutting insulation accurately and checking for gaps ensure efficient installation and maintenance practices.

Future Considerations: Consulting with HVAC professionals for expert advice on selecting the right type and thickness of insulation can further optimize the efficiency and longevity of copper pipe coils. Regular inspections and prompt repairs will help maintain the integrity of the system over time.

See Also

Exploring Optimal Insulation for Copper Tubing

Revealing Tips: Enhance AC Efficiency using Copper Tubing

Benefits of Selecting Copper Tubing for Air Conditioners