Comprehensive Guide to Thermal Insulation Materials for Air Conditioners

Enhancing the efficiency of air conditioners goes beyond mere functionality; it's about optimizing energy consumption and ensuring sustainable cost savings. This comprehensive Guide delves into the realm of thermal insulation materials for air conditioners, shedding light on their pivotal role in maintaining optimal performance. By understanding these materials, users can make informed decisions that not only improve energy efficiency but also contribute to long-term savings. Let's embark on this insightful journey to explore the world of thermal insulation in air conditioners in this Guide to Materials Used for Thermal Insulation in Air Conditioners.

Understanding Thermal Insulation

In the realm of air conditioning systems, thermal insulation plays a crucial role in maintaining optimal performance and energy efficiency. Let's delve into the fundamental aspects of thermal insulation to grasp its significance.

Definition and Purpose

What is Thermal Insulation?

Thermal insulation refers to materials or structures that prevent heat transfer between objects with different temperatures. By reducing heat flow, insulation helps maintain desired temperatures within a space, enhancing comfort and energy efficiency.

Why is it Important?

The importance of thermal insulation cannot be overstated. It significantly contributes to energy savings, reduces noise transmission, prevents fires, and prolongs the lifespan of equipment. In air conditioners specifically, proper insulation minimizes heat loss or gain, allowing the system to operate efficiently.

How Thermal Insulation Works

Mechanism of Heat Transfer

Heat transfer occurs through three primary mechanisms: conduction, convection, and radiation. Thermal insulation materials disrupt these mechanisms by impeding the flow of heat energy, thereby maintaining stable indoor temperatures.

Role in Air Conditioners

In air conditioning systems, thermal insulation serves as a barrier against external temperature influences. By insulating components such as pipes and ducts, it prevents heat exchange with the surrounding environment. This not only enhances the system's efficiency but also ensures consistent cooling performance.

Common Insulation Materials

Polyethylene Foam

Polyethylene Foam stands out as a versatile and durable material in the realm of thermal insulation. With its impact-resistant and highly resilient nature, it serves as a critical component for various applications. Its soft texture, coupled with resistance to dusting, tearing, and degradation, makes it a preferred choice for insulation needs. The properties of Polyethylene Foam include high flexibility, durability, and corrosion resistance. This closed-cell thermoplastic foam material offers an effective temperature barrier while remaining lightweight and flexible.

Properties

Impact-resistant and highly resilient

Soft texture with resistance to dusting, tearing, and degradation

High flexibility, durability, and corrosion resistance

Lightweight despite its closed-cell structure

Applications

Packaging: Used in packaging applications due to its firmness and protective qualities.

Flotation Devices: Ideal for creating buoyant flotation devices that require resilience.

Insulation: Valued for its temperature barrier properties in various insulation applications.

Fiberglass

When it comes to thermal insulation, Fiberglass emerges as a reliable choice known for its robust properties and versatile applications. This material is characterized by its strength and durability, making it suitable for demanding environments where insulation performance is crucial. Fiberglass is valued for its thermal resistance capabilities and ability to withstand varying temperatures without compromising efficiency.

Properties

Strength and durability suitable for demanding environments

Excellent thermal resistance capabilities

Ability to withstand varying temperatures effectively

Applications

HVAC Systems: Widely used in heating, ventilation, and air conditioning systems for efficient insulation.

Industrial Settings: Applied in industrial settings where high-performance insulation is required.

Residential Construction: Utilized in residential construction projects to enhance energy efficiency.

Foam Rubber

Foam Rubber, another common insulation material, offers unique characteristics that cater to specific requirements in thermal insulation applications. Known for its cushioning properties and flexibility, this material provides both comfort and protection in diverse settings where insulation is essential.

Properties

Cushioning properties ideal for comfort applications

Flexibility allowing adaptation to various shapes and structures

Applications

Automotive Industry: Used in vehicles to provide cushioning against vibrations.

Home Insulation: Applied in homes to maintain optimal indoor temperatures.

Sports Equipment: Utilized in sports equipment due to its shock-absorbing qualities.

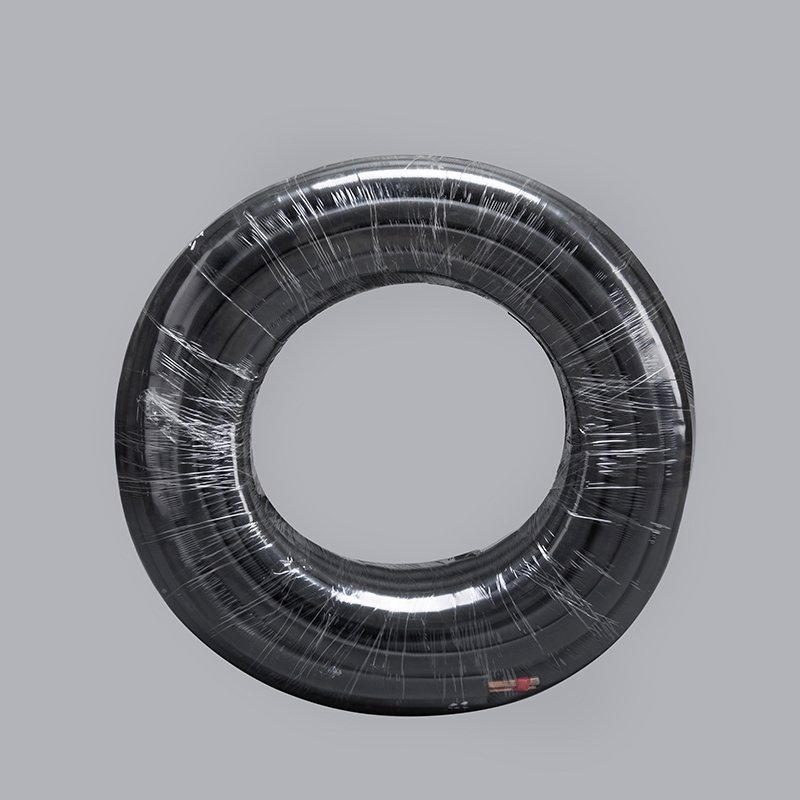

Closed-cell Elastomeric Foam

Closed-cell Elastomeric Foam stands as a top choice for insulating AC pipes due to its efficiency, flexibility, and built-in vapor barrier. This specialized foam material offers exceptional properties that cater to the unique requirements of thermal insulation applications.

Properties

Resilient and durable material

Flexible structure for easy installation

Built-in vapor barrier for moisture resistance

Efficient thermal insulation capabilities

In the realm of air conditioning systems, Closed-cell Elastomeric Foam plays a crucial role in maintaining optimal performance and energy efficiency. Its closed-cell structure ensures minimal heat transfer, enhancing the overall effectiveness of the insulation.

Applications

AC Pipe Insulation: Widely used to insulate air conditioning pipes in residential and commercial settings.

HVAC Systems: Applied in heating, ventilation, and air conditioning systems to improve energy efficiency.

Refrigeration Units: Utilized in refrigeration units to prevent condensation and maintain temperature stability.

By choosing Closed-cell Elastomeric Foam for thermal insulation needs, users can benefit from its superior properties that contribute to enhanced system performance and longevity.

Mineral Wool

Mineral Wool, a versatile insulation material, offers excellent thermal properties ideal for various applications in air conditioning systems. This mineral-based material provides effective insulation while ensuring durability and long-term performance.

Properties

High thermal resistance for efficient heat retention

Fire-resistant properties for enhanced safety

Excellent sound absorption capabilities

Durable composition suitable for long-lasting use

When it comes to insulating air conditioners, Mineral Wool stands out as a reliable choice due to its ability to maintain desired temperatures effectively.

Applications

Duct Insulation: Used in HVAC ducts to prevent heat loss or gain during air transfer.

Equipment Enclosures: Applied in equipment enclosures to regulate internal temperatures.

Industrial Settings: Utilized in industrial settings where high-performance insulation is essential.

With its exceptional thermal properties and versatility, Mineral Wool serves as a valuable solution for enhancing energy efficiency and optimizing the performance of air conditioning systems.

Choosing the Right Material

Factors to Consider

Efficiency

When selecting insulation materials for air conditioners, efficiency stands out as a critical factor to consider.

Optimal efficiency ensures that the chosen material effectively reduces heat transfer, enhancing the overall performance of the air conditioning system.

Closed-cell elastomeric foam insulation is renowned for its exceptional efficiency in controlling condensation and preventing mold growth on cold mechanical systems.

This type of insulation offers a flexible closed-cell structure that effectively minimizes heat exchange, contributing to energy savings.

Cost

Cost plays a significant role in the decision-making process when choosing insulation materials for air conditioners.

It is essential to strike a balance between quality and affordability to ensure long-term cost-effectiveness.

Mineral Wool, which contains an average of 70% post-industrial recycled content, provides high fire resistance at a competitive price point.

By opting for cost-effective solutions like mineral wool, users can achieve efficient insulation without compromising on performance or sustainability.

Durability

The durability of insulation materials is crucial for maintaining long-lasting thermal performance in air conditioning systems.

Selecting durable materials ensures that the insulation remains effective over time, reducing the need for frequent replacements.

Closed-cell elastomeric foam insulation offers a durable solution with low-VOC emissions and fiber-free composition, making it ideal for various applications.

With its resilient properties and ability to withstand environmental factors, this type of insulation guarantees prolonged efficiency and reliability.

Enhancing air conditioning efficiency requires a strategic approach to thermal insulation. By carefully selecting the right materials, users can optimize energy consumption and achieve sustainable cost savings. The key lies in understanding the significance of proper insulation, which not only enhances comfort but also contributes to long-term equipment durability. Looking ahead, future trends emphasize factors like R-value, ease of installation, and cost-effectiveness in insulation choices. As expert Brian Pontolilo suggests, prioritizing criteria such as air permeability and moisture tolerance can lead to significant improvements in energy efficiency. Improving the thermal performance of building envelopes remains crucial for overall energy conservation efforts.

See Also

Enhance Air Conditioner Performance with Copper Pipe Insulation

Revealing the Top 5 Effective Insulation Materials

Complete Guide to Insulation Thickness: Essential Information

Comparing Efficiency: Copper vs. Aluminum Tubing in Air Conditioning

Revealing the Cooling Benefits: Pure Copper Tubing for AC Units